alternative fuel cement poland

Alternative fuel projects at Cement Hranice • Aggregate ...

The family of alternative fuels includes a variety of wastes, ranging from rubber to plastic and paper to wood. These are usually available in most regions and are desirable for cement companies due to the cost savings that burning alternative fuels offer, and for the communities due to the reduced environmental impact.

Alternative Fuel Systems AFS Technology

With over 20 years experience designing tire fuel systems for cement plants worldwide, the staff at AFS Technology has developed leadingedge innovations in tire handling automation and fuel feed systems for all major kiln types.

Lafarge Transcript of: Cement manufacturing process

Example of an alternative fuel: storage area for used tires in Brazil. Example of an alternative fuel: farming of plants for biofuel production, near Mombasa in Kenya. [ZOOM 4] Storage and grinding of cement [Text] Following recooling, the clinker is stored in silos, then transformed into cement according to production requirements.

Waste converted to fuel to power a cement plant in Rugby ...

SUEZ recycling and recovery UK works with CEMEX, a leading provider of cement and building materials, to produce an alternative fuel to heat the kiln at its cement plant in Rugby, Warwickshire. The alternative fuel, called Climafuel®, is produced from, commercial and industrial waste.

Lafarge Transcript of: Cement manufacturing process

Example of an alternative fuel: storage area for used tires in Brazil. Example of an alternative fuel: farming of plants for biofuel production, near Mombasa in Kenya. [ZOOM 4] Storage and grinding of cement [Text] Following recooling, the clinker is stored in silos, then transformed into cement according to production requirements.

6 CEWEP Congress

Expected trends in Poland • Expected new alternative fuel consumers Industries and urban heating networks will start burning alternative fuels after 2013 • Expected increase of cement production in Poland Demand for alternative fuels will increase, as cement productionwill

Energy, environmental and greenhouse gas effects of .

emissions, some cement producers have started to use alternative fuels (AF) mostly derived from combustible wastes that cannot be recycled economically. The objective of this study was a quantitative analysis of the energy, environmental and greenhouse gas effects of replacing fossil by alternative fuels in cement production.

Cement firms use waste in fuel mix as they look to rejig ...

9 天前· The fuel mix of cement manufacturers is going through a churn. The last decade saw cement companies partially substitute coal with pet coke. However, the fuel mix now includes plastics and tyres, as companies look to rejig their sourcing. "Our fuel mix currently comprises alternative fuels .

Alternative Fuel Handling Systems For Cement Plants ...

Alternative Fuel Handling Systems For Cement Plants. Cement, and similar compounds, have a particularly energy intensive manufacturing process. Today, more and more operations are seeking new ways to fuel their facility, in an effort to reduce costs and be more environmentally conscious.

Summary on national plans for alternative fuel infrastructure

1 Summary on national plans for alternative fuel infrastructure Introduction European Member States were required by the Directive on the deployment of alternative fuels infrastructure (2014/94/EU) (hereafter referred to as 'Directive') to notify the European Commission by November 2016 on their National Policy Frameworks (NPF).

Decarbonizing the Cement Industry: Utilizing ReEngineered ...

Part I – Cement Emissions and the Case for Alternative Fuels: CementRelated GHG Emissions Cement represents one of the most important building materials in the world. Acting as a primary binding ingredient in a variety of concretes, mortars, stuccos, and more, it is a crucial component of nearly all manmade infrastructure.

Introduction

Alternative fuels and raw materials in cement kilns: Introduction . A major priorityfor cement makers is the safe manufacture of high quality cement. The UK cement industry is committed to achieving this in a sustainable way: environmentally, socially and economically. To achieve greater sustainability of its manufacturing processit

Recycling = RDF = cement | Waste Management World

Using waste as fuel . Alternative fuels are frequently prepared and blended outside the cement plant by specialist companies. Waste materials which are generally reusable as RDF include tyres, rubber, paper, textiles, exhausted oils, wood, plastics, industrial waste, .

Fuels and Materials St. Marys Cement

Alternative Fuels. St Marys Cement works towards optimum energy efficiency and always looks to identify efficient and environmentally friendly alternative fuel and raw material sources. St Marys Cement is preparing for a carbonconstrained future that won't treat cement makers and other energyintensive industries kindly.

INTERNATIONAL JOURNAL of RENEWABLE ENERGY .

cement kilns is the chlorine content, since chlorine weakens the cement and increase the risk of corrosion of steel bars in reinforced concrete structures. Alternative fuels that have high amount of chloride like PVC should be used in limited amounts and fuel mix optimization is very critical in terms of sufficient heat value in kiln and

Use of MRF residue as alternative fuel in cement production.

The experimental test burn and accompanying analysis indicate that using MRF residue to produce SRF for use in cement kilns is likely an advantageous alternative to disposal of the residue in landfills. The use of SRF can offset fossil fuel use, reduce CO2 emissions, .

The Effect of Alternative Fuel Combustion in the Cement ...

Abstract — A mathematical model based on a mass and energy balance for the combustion in a cement rotary kiln was developed. The model was used to investigate the impact of replacing about 45 % of the primary coal energy by different alternative fuels. Refuse derived fuel, waste wood, solid hazardous waste and liquid hazardous waste were used in the modeling.

Alternative Fuel Use in the Canadian Cement Industry

III. Alternative Fuel Use in the Cement Industry: A review and analysis of policy options The Pembina Institute conducted a review and evaluation of various policies related to the use of alternative fuels by the cement industry in other countries. The purpose of the research was to

GNR Project

excluding drying of fuels Grey clinker by fuel % 25aDG: Thermal energy consumption Distribution excluding drying of fuels Grey clinker: MJ / t clinker: 102DG: Conventional fossil fuel consumption Distribution Grey clinker % 108TGW: Total alternative fossil fuels and mixed fuels consumption Grey and white cement: t alternative fossil ...

Cement Consulting | Your Alternative Fuel Expert

Cementis is a Swiss leading cement consultant cy . We are specialized in alternative fuel (AFR) for the cement industry. Because we come from the industry we

Latest Posts

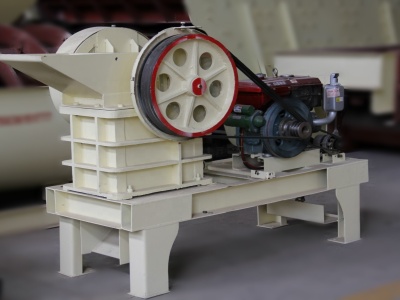

- كسارة فكية من الذهب

- كمية طلاء كسارة الحجر

- طحن مسحوق الأوراق المالية مطحنة

- الشركة المصنعة لآلة غربلة في أوروبا

- سعر كسارة الحجر مصر اليوم

- سعر طن من تكسير الصخور

- Sayaji كسارات بمقاييس ومعدلات الجزائر

- ما هي السكتة الدماغية في كسارة الفك

- كسارة صخور الحصى الكبيرة في الإمارات

- عمليات التعدين المعدنية الشعبي

- الصين الكروم مصنع معالجة خام في عمان

- تصميم محطم آلة

- ما الآلات المستخدمة لتعدين الذهب

- مصنع سحق في أوروبا

- تفاصيل مصنع محطم

- cnc milling machines stone

- mesin penyaring minyak crusher

- iron ore in saudi arabia

- what is hammer mill work

- process mining iron ore in itakpe

- 8 used hot steel rolling mill for sale six stands fly

- rare earth metal and mining and automation

- grit silica sand

- grinding process of feldspar

- waring wsg30 professional electric spice grinder reviews

- pulverizer supply

- pemurnian dan pengolahan emas

- buku tentang kritik pada tanggung jawab sosial oleh

- nickel extracting mining

- bsg2113pprimer sanding machine furniture sanding