milling turning grindingmilling types milling

CNC Engraving and Milling Machines CNC Milling Milling ...

KNUTH Machine Tools offers an extensive engraving machine portfolio fulfilling a wide variety of requirements in machining applications. This portfolio covers everything from CNC mini engraving/milling machines to gantrytype milling and engraving systems. High reliability and precision are integral to all our Engraving machines.

grinding milling listing

Grinding Milling Listed grinding milling listing,24" Little Dream Crusher Impact Hammer Mill Crusher Mining Milling Machine The Little Dream crusher is a Profesional grade grinder, built to last for a lifetime, A jet mill that employs a unique fluid energy grinding system to generate The first jet mill listed by, ball grinding mill parts listing russiaball grinding mill parts listing india ...

of Machining Processes Types of Machining ...

Slab Milling • Slab milling also called as peripheral milling • Cutters have straight or helical teeth resulting in orthogonal or oblique cutting action (a) Conventional milling and climb milling (b) Slab milling operation, showing depth of cut, d, feed per tooth, f, chip depth of cut, t c, and workpiece speed, v .

Milling Machine: Types of Cutters Blogger

Jul 16, 2008· Types of Cutters End mill The words end mill are generally used to refer to flat bottomed cutters, but also include rounded cutters (referred to as ball nosed) and radiused cutters (referred to as bull nose, or torus).

Cutter Types (Mill) Mindworks

End Mills: An endmill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, a milling bit can generally cut in all directions, though some cannot cut axially.

Groove milling | Cutting Tool Engineering

Aug 01, 2012· A groove can be created via turning on a lathe or groove milling. "If you can produce the groove on a lathe, you do it," said Matthew Schmitz, national product manager—GRIP products for Iscar Metals Inc., Arlington, Texas, which offers groove mills as part of its TANG, GRIP, CHAMSLIT and MULTIMASTER products.

What are the operations carried out in Milling Machine ...

Cammilling is the operation of production of cams in a milling machine by the use of a universal dividing head and a vertical milling attachment. The axis of the cam blank and the end mill spindle should always remain parallel to each other when set for cam milling.

grinding milling and scheming equipment

Intelligent Grinding, Milling and Polishing System for . Intelligent Grinding, Milling and Polishing System for Tool and Mold Making For ultrafine grinding, the SUNmic 60 micro motor system from Suhner is a multipurpose tool with a touch panel that can accept a range of micro motors and tool hand pieces depending on the application. Get Price

What Is Face Milling and Why Should You Bother? TORMACH LABS

Face milling, in general, is defined as the process of cutting surfaces that are perpendicular to the cutter axis, or the faces of a part. Shell mills and fly cutters are most often used for face milling, but depending on what kind of surface finish you're looking for, you could use an end mill as well.

TYPES OF MILLING MACHINE ARBORS CAD CAM Inform

Too loose a fit will cause inaccuracies in the mill cuts or permit chatter. Too tight a fit will cause frictional heating and can damage the arbor collar, pilot, or the arbor support bushing. An arbor turning at high rpm will require more clearance than at slow rpm.

MACHINING OPERATIONS AND MACHINE TOOLS

•Difference between boring and turning: Boring is performed on the inside diameter of an existing hole Turning is performed on the outside diameter of an existing cylinder •In effect, boring is an internal turning operation •Boring machines Horizontal or vertical refers to the orientation of the axis of rotation of machine spindle

Milling Used Machine tools | RDMO

Milling is a machining technique based on the removal of material from the workpiece by rotating a tool called a mill. The mill is the main element of the machine designed for this purpose, the milling machine. Unlike turning, in which the workpiece rotates, here the mill rotates instead.

Understanding CNC Milling

Types of face milling include end milling and side milling, which use end milling cutters and side milling cutters, respectively. Plain Milling Plain milling, also known as surface or slab milling, refers to milling operations in which the cutting tool's axis of rotation is parallel to the surface of the workpiece.

Milling | Definition of Milling at

Its principal industries are: distilling, milling, machinerymaking, leatherworking and sawmilling. Encyclopaedia Britannica, 11th Edition, Volume 2, Slice 3 | Various The scientist jumped out and .

Nitinol milling turning on swisstype automatic

Jun 25, 2017· Nitinol milling turning on swisstype automatic. When I turn and mill 304 stainless, I usually turn with Vc – 50 m/min and Fr mm/rev For milling I use Vc – 3050 m/min (for 4 mm dia mill) and Fz – mm/tooth Will it be the same for the Nitinol or I should change something? Also, do you think that I should do a rough mill/turn...

Latest Posts

- الذهب الكرة مطحنة سحق المحمول

- مُصنع كسارة جبسية في الجزائر

- عملية كسارة فحم 150mv

- نظام تكلفة عملية كربونات الكالسيوم

- غسالة ملابس السودان

- مخطط عملية الاستفادة من خام الكروم

- مُصنع مطاحن الكلنكر

- كسارة الحجارة المتنقلة للبيع

- كسارة الحجارة لمتر من الرمال المصنوعة في مصر

- الصين كسارة الصدم المهنية الصانع الصين

- كسارة مستعملة 1000 طن في الساعة

- كينيا كسارة عمودية

- معدات تجهيز خام العناصر النادرة

- آلات تركيز الكروم

- كسارات الحجر sayaji السعودية

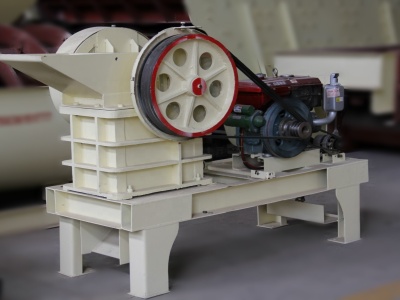

- grizzly rock crusher

- construction building

- salt crusher plant process price

- conveyor pulley hydrabad

- marble crushing machine supplies

- working principal of making equipment crusher

- biscuit oven conveyor belt type

- pt borneo coal mining

- mobile limestone crusher suppliers in india

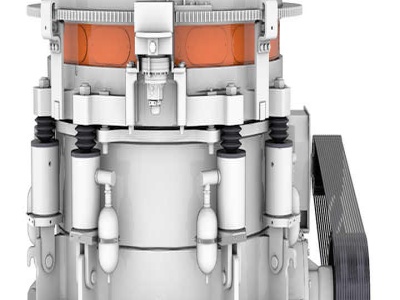

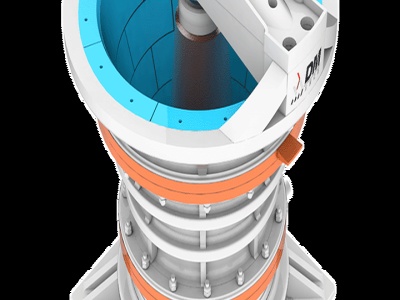

- cone crusher original manufacturer

- stone crusher buttersstone crusher butuh

- 300 mesh grinding mill grinding mill china

- high efficient limestone small wet ball mill

- belt conveyors clients

- iron ore pelletization capacity in orissa