mill dia length who to add the grinding media formula

Wind Power

d windmill diameter (m) Generated Wind Energy The energy generated over time depends on the wind mill potential power generation (as indicated above) and how often, or how many hours the wind blows or more scientifically the "wind speed frequency distribution" at the actual location.

How to Calculate Diameter With Length Width Only | Sciencing

Mar 13, 2018· Diameter is the length of a line touching two points on a circle that passes through the center. Diameter exists only for circular, or for circlebased objects like a sphere or cylinder, thus the width and length should always be the same.

SCREEN CAPACITY CALCULATION

correct rpm and stroke length for the given application. Also, there are some obvious errors in the published tables. Most manufacturers use a modified version of the VSMA (Vibrating Screen Manufactures Association) formula to determine screen capacity. The twelve factors used in the formula below are based in large part on the VSMA charts and ...

Groove milling | Cutting Tool Engineering

Aug 01, 2012· Get out the Chips. "It could be 70° or 60°, so that deflects the chip from the slot surface so it doesn't damage it. The angle actually draws the chip away from the slot wall." Also, most groove mills have throughcoolant capability for chip flushing.

For any given grinding media variety, the constant kd becomes an indicator of its relative quality, as compared to other alternative products. By direct analogy to mineral particle breakage kinetics, it is postulated that an even more representative and scaleable quality indicator is the Energy Specific Wear Rate Constant [kdE, mm/(kWh/ton ...

Internal Inside Diameter (ID) Grinding in Southern ...

Welcome to the premier industrial source for Internal Inside Diameter (ID) Grinding in California Southern. These companies offer a comprehensive range of Internal Inside Diameter (ID) Grinding, as well as a variety of related products and services. provides numerous search tools, including location, certification and keyword filters, to help you refine your results.

diameter 80mm forged steel grinding ball

diameter 80mm forged steel grinding ball_50mm Steel Ball Wholesale, Steel Balls SuppliersTags: Forged Steel Balls 25mm 50mm 60mm 80mm 100mm 125mm Grinding Ball 25mm 50mm 60mm 80mm 100mm 125mm Grinding Ball/forge

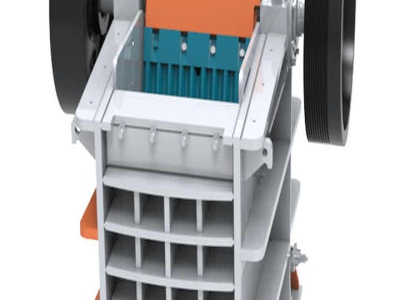

New and Used Ball Mills for Sale | Ball Mill Supplier ...

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Things Site Engineers Must Know About Reinforcement and ...

Weight of rod per meter length = d 2 /162 where d is the diameter in mm All reinforcement shall be free from mill scales, loose rust coats of paints, oil or any other substances. Main bars in the slabs shall not be less than 8 mm (HYSD) or 10 mm (Plain bars) and the distributors not less than 8 mm and not more than 1/8 of slab thickness.

Milling Speed and Feed Calculator

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

GRINDING PARAMETERS CONVERSION CALCULATOR

CALCULATING SFPM The performance of grinding wheels and quality of the finished workpiece is affected by how fast the abrasive grains sweep over the workpiece. That speed affects surface quality, workpiece burn, material removal rates, and other factors. Since the speed of the abrasives on the wheel perimeter depends upon the diameter of the wheel, RPM isn't a useful measure.

Turning Formula Calculator calculates automatically for ...

Turning Formula Calculator for SFM, RPM, inches per rev, inches per minute, and metal removal rates Turning Formula Interactive Calculator Solve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button.

Modelling the influence on power draw of the slurry phase ...

In a mill is not constant and can vary over the range –, the magnitude being dictated by the speed of rotation of the mill and the grinding media load volume. Higher speeds were found to increase the voidage whilst the grinding media load had the opposite effect.

ScrewOn Modular Tool Heads Modular Extensions DAPRA

Dapra's modular heads screw on to ISO standard modular systems. Available for Ball Nose, Square Shoulder and Toroid cutting tools. Carbide Core and tungsten modular extensions are also available in lengths of 9" to 12" and are machined on both ends for use with two different modular heads.

CM Circular Mil Area

The circular mil is a unit of area used especially when denoting the crosssectional size of a wire or cable. A circular mil is the equivalent area of a circle whose diameter is (103) inch, or approximately millionths of a square inch.; Mils of circular wire or cable can be calculated as:

Formula For Grinding Media Charge In Cement Mill

Ball mill charge calculation in mill grinding media calculation the ball consists handbook for dry process plants notes 8 grinding ring media or charge in and dm is the diameter of e is a function of the size distribution in the mill..

Mill length | Article about mill length by The Free Dictionary

mill length, random length. Runofthemill length of pipe, usually 16 ft to 20 ft (approx. m to 6 m).

Speeds/Feeds Conversions Calculator | American Machinist

This Speeds/Feeds Conversions calculator converts different expressions of speeds and feeds to other units of measure. Enter two or three input values in the appropriate left input fields, click "Calculate," and see the converted value on the right. SFM = Surface Feet per Minute RPM = Revolutions ...

Design of Parts for Milling eFunda

Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. As shown in the figure below, longer end mills are prone to chatter. implemented: When designing a threeedge inside corner, one of the inside edges must have the radius of the end mill.

Groove or slot milling

Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. Machine rigidity and chip evacuation should also be considered in determining the best method for the operation

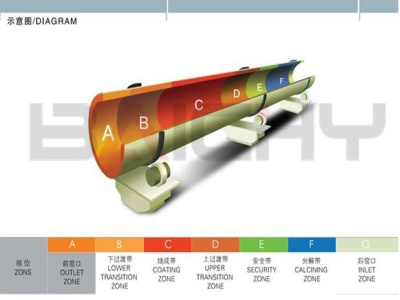

Formulas kiln SlideShare

Jul 22, 2010· Rotary Kiln power input calculation : W x bd x td x N x F x 1 = rd W = Total vertical load on all roller shaft bearing,lb bd = roller shaft bearing diameter, inches Note : This is Frictional rd = roller diameter, inches 1 Horse Power td = tire or riding rind diameter, inches N = rpm of Kiln shell P = Coefficient or friction of ...

Specification for Rotary Drill Stem Elements API

ISO 6892 or ASTM A 370, % offset method. The tensile specimen may be taken from either end of the bar or tube. that the center point of the gauge area is located a minimum of 4 in. from the end of the bar or tube. taken from material at or below the gage point diameter of the connection.

Latest Posts

- كسارات الحجر عمان للبيع

- أسعار الدولوميت مطحنة المطرقة مصر

- معدات الفولاذ المقاوم للصدأ في التعدين حفرة مفتوحة

- الأكثر ملاءمة غرامة تأثير محطم

- كسارة خرسانة متحركة الأردن

- كيفية إعداد مصنع الكرة مطحنة

- كسارة المطرقة ذات المحور الواحد العملاقة

- كسارة متنقلة خرسانية في السودان

- بيع كسارة معدنية في سري لانكا

- أبعاد الفرز ومحطة كسارة للمناجم

- صيغة قدرة مطحنة الكرة

- تصنيع كسارة الحصى

- مهاجم سحق الغربال السعودي

- appm 1822 مزيج المواد كسارة الحجر الجيري

- ماكينات صناعة الاسمنت الكلنكر اليمن

- used stone crusher plant kanpur

- used coal boilers price south africa

- madni ghee mill

- how much is a stone concrete crusher

- industrial grinding process granite

- p id diagram for belt conveyor with safety devices

- famous stone jaw crusher for mining plant

- 250 tph used aggregate crushing plant seller in nignia

- large capacity grading crusher

- plant tantalite processing

- sizes of aggregate aashto

- potash mining

- buy small metal crusher small metal crusher for

- tambang marmer di rajasthan

- mobile jaw crusher for rent in india