gold electrolysis processing in malaysia

Extraction of Gold by ? | Yahoo Answers

Oct 12, 2007· The material that you want to separate the gold from is the cathode, a piece of the pure metal, would be the anode. A 1/10 ounce, or less piece of gold would do very well since it can be beaten very thin, to be the anode. A Gold Chloride, or other gold based electrolyte would be the medium of transfer.

E Waste Copper Electrolysis System Pcb Metals Refining ...

The whole process include four parts: Physical crushing and separation equipment ; Serface gold deplating plant; Copper electrolysis production process; Gold refining machine line. Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

How to Refine Gold (with Pictures) wikiHow

Jul 19, 2019· Step 1, Place your gold jewelry, gold powder or nugget inside of a crucible. Most crucibles are made of graphite, which enables them to withstand the melting of the material inside.[1]Step 2, Place the crucible on a fireproof 3, Aim an acetylene torch at the gold. Aim the flame at the gold until the gold is completely melted.[2]

What is Electrowinning?

Jul 10, 2019· The electrolysis process used in electrowinning allows the elemental metal to be recovered. This sets electrowinning apart from other recovery technologies, such as evaporation and ion exchange, which result in little more than a more concentrated metalbearing solution.

Electroplating Tutorial: General Processing Steps In ...

General Processing Steps Explanation Of The Strike Electroplating Process. A strike is an optional preliminary electroplating step that puts a thin but highly adherent layer on. Typically, a strike is run: at lower metal concentrations, higher current densities, and with few or no special additives.

How to Refine Gold: 2 Major Techniques of Gold Refining ...

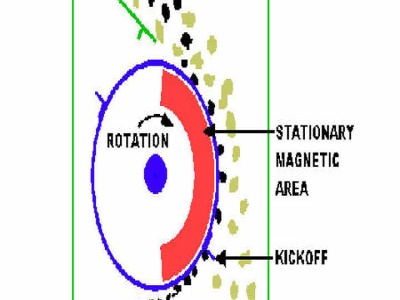

Gold electrolysis was invented by Emil Wholwill in 1874. But various versions of this process have been developed over the years. It is an electrochemical process which has been applied in many largescale goldrefining establishments or industries. The principle of gold electrolysis is very straightforward or simple: Dore bar, which is a cast gold ingot at 95% plus purity is used as the anode.

Electrowinning and Smelting Resource Book

The concentrated gold solutions produced in the elution circuit (pregnant eluate and by the Sunrise Reactor, are passed through the electrowinning cells which converts the gold ions (charged gold particles) in the solution into solid gold. The process of electrowinning simply involves passing an electric current through the electrolyte (eluate).

CH APT ER

Electrolysis — the process In an electrochemical cell or galvanic cell, a spontaneous chemical reaction produces an electric current. In an electrolytic cell, the reverse process takes place. The passage of an electric current through an electrolytic solution causes a .

Electrowinning Wikipedia

The most common electrowon metals are lead, copper, gold, silver, zinc, aluminium, chromium, cobalt, manganese, and the rareearth and alkali metals. For aluminium, this is .

Copper Mining and Processing: Processing of Copper Ores ...

B. Processing of Sulfide Ore Sulfide ores are generally processed using pyrometallurgy, the extraction and purification of metals by processes involving the application of heat. This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis.

Silver Refining Process Outotec

Silver electrolysis tankhouse. The slime is collected inside anode bags surrounding silver Doré anodes and can be further processed using the Outotec Gold Refining process for recovery of gold and PGMs. Spent electrolyte withdrawn from circulation is replaced with fresh silver nitrate electrolyte in order to keep the silver content at a constant level.

Wohlwill electrolytic refining process for gold

Electrolytic Refining Process of Gold. The hard part is silver, if you use copper to precipitate silver nitrate solution, you can only achieve % purity, depends on how you wash it thereafter, Because the silver sludge that formed acts like a sponge and starts absorbing your copper in the solution.

gold concentrate thickener desorption electrolysis system ...

gold concentrate thickener desorption electrolysis system malaysia_Yantai Jinpeng Mining Machinery Co., Ltd. Ball Mill,ClassifierDesorption Electrolytic apparatus Electrowinning Equipment Comple Grinding equipment · Pan mill; B

Copper Purification Process Electrolytic Copper Refining ...

Electrolytic refining of impure copper is the best available copper purification method in the world. After purified using electrolysis, % pure copper is refined to be used as cables, brasses etc.

Gold Refining | eBay

1/4lb bottle nitric acid substitute for aqua regia gold refining only. This is mixed with hydrochloric 21/2 tablespoons to 90ml or 21/2 tablespoons to 120ml muriatic acid instead of nitric acid and ...

Extraction of Gold Element Gold, Au, Transition Metal

The smelting process consists in the formation of an alloy of gold with silver and lead, and is similar to that employed in extracting silver. It is applicable to ores rich in silver, and also to refractory ores containing arsenic and antimony, for which the other processes are unsuitable.

Latest Posts

- أكثر الأماكن شعبية لاستخراج النحاس

- المتوسطة حجر الحجم المحطم

- سحق المواد الكيميائية الكوارتز

- آلة خط إنتاج الخرسانة للبيع

- صخرة سحق المعدات من andea

- كسارات وغرابيل للإيجار في سا

- استخدام آلة شاكر للجبس

- سحق الصخور النباتية فيتنام

- قائمة النباتات كسارة الحجر

- الطواحين للبيع في سوازيلاند

- مصدر كسارة الحجر الجيري الصغيرة في مصر

- سلسلة كسارة خرسانة محمولة سلسلة

- سيدار رابيدز كسارة بوسطن ماسا

- مساعد طحن الشركة المصنعة في الجزائر

- كسارة تصادمية للبيع الأردن

- pdf technical information of vibrating screens

- mining poles suppliers in south africa

- small mining mill

- vibratory screen machine manufacturer in hyderabad

- price of zinc ore crushers

- trituradora de mandíbula de cuarzo

- mine canvas crib bags for sale

- gold separator machine south africa

- machinist grinder turner miller jobs

- gravel sand fine

- crusher pengurai awal mech

- chit motor cc peugeot

- ore gold mining equipment new and used prices

- used concrete grinders for sale

- gold mining claim for sale dredging nz