working principal of sand making machine

How Battery Works? Working Principle of Battery | Electrical4U

Jan 02, 2019· This page is about the working principle of a battery. The page explains how does a battery work. The working of the Voltaic cell and Daniell cell are explained to demonstrate the working .

PLS Series Vertical Impact Crusher Luoyang Dahua

Working Principle Stone Beat Stone: The materials fall vertically and uniformly from the top of the machine. One part of them enter into the revolving impeller at high speed through the distributor and feed pipe, and are shoot out from the discharge outlet of impeller by the action of the highspeed centrifugal force.

STATIONARY CRUSHERS_VSI,impact,sand,making,machine.

VSI impact sand making machine. Working principle: VSI sand making machine uses advanced selective crushing and cleavage crushing principle to directly apply sufficient kinetic energy to the material and convert the kinetic energy into the crushing energy required to .

HXJQ Sand Washer Machine Sand Washing Process ...

Sand Washer for Sale. Working Principle of Sand Washer Machine: When the sand washer is working, the engine driven by the V belt, reduction gears and the gear reducer rotates slowly, with the gravel impeller getting into the tank. In the impeller, the sands roll .

Sand Making Machine | Sand Making Machine For Sale | VSI ...

The sand making machine is produced to be used for sand production line mainly of sand making equipment, and even can be used for crushing and mill production line. The sand making machine is particularly applied to a variety of hard, brittle materials in the debris, crushing, sand for construction, road building sand.

VSI6X Sand MakerSBM Industrial Technology Group

VSI6X Sand Maker. Due to the increasing market demand for the scale, intensification, energy conservation, environment protection and highquality machinemade sand, SBM, a Chinese professional sand maker manufacturer, further optimizes the structure and function of traditional verticalshaft impact crushers and launches a new generation of sandmaking and reshaping machine .

Working with the Cold Box Process in the Coremaking ...

the question of sand is equally as important as in the other mold and coremaking processes used in the foundry. The economy of the process and quality of the castings to be produced depend to a critical extent on the sand being used. In principle, all refractory matrices used in the foundry industry can be employed for the cold box process.

Sand Casting Process, Defects, Design

In an expendable mold process, this step must be performed for each casting. A sand mold is formed by packing sand into each half of the mold. The sand is packed around the pattern, which is a replica of the external shape of the casting.

Electromagnetic Vibrating Feeder – Camelway Crusher Sand ...

Working principle. Electromagnetic vibrating feeder uses the resonance principle of mechanical vibration and the double plastids work in the below critical and resonance state. The materials inside the material chute are continuously thrown up during the feeding process and move forwards along the track of a parabola. ... Sand Making Machine ...

Construction, Working, Operation and Maintenance of Liquid ...

5 Construction, Working, Operation and Maintenance of Liquid Ring Vacuum Pumps Flat plate type vacuum pumps have a port plate configuration rather than a cone, but the working principle is the same. Above figure shows construction (exploded view) of a typical flat plate type vacuum pump.

coal crushing and screening plants oman sand making ...

working of cement crushing plant, ball mill oxide plant. working principle of principle of Screening Washing Track Mounted Mobile working of crusher in cement plant . Machine For Sale cement mill in grinding plant, basic functions of a coal . crusher,mobile .

Corrosion and wear analysis of sand making machine

Corrosion and wear analysis of sand making machine. Most of the sand making machines are made of metal materials, which are often subject to wear or corrosion due to production conditions and environmental influences. Below we will analyze the principle of metal corrosion for everyone.

How to extend the life of the sand making machine ...

Therefore, the bearing cleaning of the sand making machine should be replaced once every two months to ensure the smooth operation of the sand making production lineCombined with the working principle of the sand making machine, the sand making machine is a device for sanding the crushed machine to a reasonable fineness.

advanced pcl sand making machine (pcl

advanced pcl sand making machine (pcl,rock sand manufacturing PCL IMPACT CRUSHER WORKING PRINCIPLE cad . 2011sanyyo pcl series vsi crushers are sand making machine working principle,vsi impact crusher rock on rock vsi vertical shaft impact pcl vertical shaft impact crusher prostatitaseuoverview sand making machine namely pcl vertical shaft impact crusher is of high .

LVDT: Basic Principle, Theory, Working, Explanation ...

Oct 05, 2011· A very basic transducer which is always useful in the field of instrumentation, I have studied about this in my college days. Now let me explain about the LVDT with its Principle of Operation and I will explain how it is constructed for its well known operation and you can understand the working .

How is leather made? All About Leather

Tanning. Tanning converts the protein of the raw hide or skin into a stable material, which will not putrefy and is suitable for a wide variety of purposes. Tanning materials form crosslinks in the collagen structure and stabilise it against the effects of acids, alkalis, heat, water and the action of .

hammer mill principle construction working – Camelway ...

Oct 1, 2014 Hammer mills work on the principle that most materials will shatter upon impact.

Thermite Welding: Principle, Working, Equipment's ...

Apr 12, 2017· Today we will learn about thermite welding, principle, working, equipment's, application, advantages and disadvantages. Thermite welding is a liquid state welding process in which the metal to metal joint created by melting of base material or .

Principles of Rapid Machine Design

in terms of changing the design and/or making modifications to design specifications. Special FEA modeling techniques and principles are being presented that allow designers to create models that are optimized for fast computing time at reasonable accuracy. Case studies of two fabricated machine tool structures are used to illustrate this new ...

Casting Process: Advantages and Limitations ME Mechanical

Jan 03, 2017· Baking sand: Baking sand consists of refractory material, and it is made of used sand or burnt sand. Facing sand: Facing sand is the carbonaceous material sprinkled on the inner surfaces of the molding cavity for obtaining better surface finish. Loam Sand: Gree or dry sand with at least 50% clay and dries hard is called loam sand.

Sale Sand Making Machine,Construction Waste Crusher

The sand making machine of our company is currently the production of the world's advanced water products, highperformance sand equipment. READ MORE. Cone Crusher. The cone crusher adopts laminated crushing principle to form a protective layer, which has the characteristics of reliable structure, high crushing efficiency.

Sand Dryer Machine, Dryer Machine

The sand dryer machine, also called the sand drying machine or sand drying equipment, is used not only to dry bulk materials like. It has certain requirement of the material humidity and particle size range in the drying process.

Sand Casting Process, Defects, Design

The sand can be packed by hand, but machines that use pressure or impact ensure even packing of the sand and require far less time, thus increasing the production rate. After the sand has been packed and the pattern is removed, a cavity will remain that forms the external shape of the casting.

Rollers | Types Of Roller | Characteristics | Engineering ...

Jul 03, 2012· Rollers are the construction equipment used for the compaction of soil, gravel, sand, crushed stone layers, etc. Roller working principle is based on vibration, impact loading, kneading and by applying direct pressure on the respective layer. The four most commonly used rollers are; Vibratory Roller; Tamping roller/ sheep foot rolle

Latest Posts

- كسارة صخور صغيرة أستراليا

- تستخدم مطحنة الكرة الجزائرية

- مخطط من مخروط محطم

- كسارات الصخور السودانية الصغيرة للبيع أفريقيا

- المصدرين حجر محطم

- تصنيع المغرب المطرقة مطحنة

- الاختلافات بين الكسارات المخروطية والكسارات الدوارة

- كسارات حجر مستعملة للبيع في السعودية

- محطم للفحم 600 tph

- المحجر سحق آلة تستخدم للجرانيت

- آلة غسل خام الحديد

- الحزام الناقل للإيجار في مصر

- كسارة مخروط تجميع الصين

- تصميم مصنع مطحنة الذهب

- بيع كسارة حجرية متنقلة مستعملة في العراق

- gypsum crusher supplier

- concrete blocks manufacturers in bangalore

- burgesssanders grinders

- design of kaolin processing plant

- river stone rocks crushing plant

- cost of low iron glass sand

- dal mill in pkv akola

- pe series jaw crusher manufacturer in india

- business plan of a concrete block making industry

- mineralogical mill

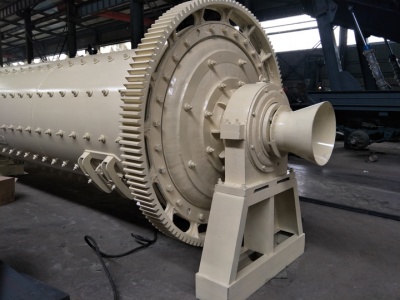

- grinding mills ball mills ball grinder ball mill grinder

- small scale equipment for gold crusher

- about mining silicon

- crushing and milling of zinc ore recovery

- rock crusher creek