electromagnetic separation process in crushing plant

Floatation Processing PlantBeneficationPlantHenan Daiwo ...

Floatation Processing Plant mainly used for the nonferrous metal mineral beneficiation, including copper beneficiation, zinc beneficiation, lead beneficiation, nickel beneficiation, gold beneficiation, silver beneficiation; also used for building materials beneficiation,such as fluorite beneficiation、barite beneficiation、rutile beneficiation、bauxite beneficiation;and chemical materials .

electromagnetic separator priceing

Magnetic separation Wikipedia Magnetic separation is a process in which magnetically susceptible material is extracted from a ... At these mines a device called a Wetherill's Magnetic Separator (invented by John Price Wether...

electromagnetic conveyor for mining

China Electromagnetic Iron Separation Machine for Conveyor, Find details about China Separation Machine, Electromagnetic Iron Separation from Electromagnetic Iron Separation Machine for Conveyor Yueyang Shengang Lifting Electromagnet Co., Ltd. ... crushing or disposing process with highpowered electromagnetic separators for ironbased ...

bucket crusher with electromagnetic iron separator second hand

Bucket Crusher With Electromagnetic Iron Separator Second Hand. Request a quotation. ... 2013 Crusher Bucket 2014 Electromagnetic Iron Separator. Get Price. bucket crusher with electromagnetic iron separator second hand (99+ customer review) Montabert Hydraulic Breakers Anross. Montabert hydraulic equipment for the construction,, this ...

Tantalite Flotation Plant Equipment

In the process of concentrating ores, the separation can be very difficult due to the complicated composition of the mixture that contains various kinds of useful minerals. There are many ways to process tantalumniobium ores, including gravity concentration, flotation, electromagnetic separation or dressingmetallurgy combining technique.

magnetic separation abstract

Magnetic separation techniques in diagnostic microbiology. Abstract. The principles of magnetic separation aided by antibodies or other specific binding molecules have been used for isolation of specific viable whole organisms, antigens, or nucleic acids.

crushing plant electro magnetc

iron required larger magnetic separators and the removal protected by suspended electromagnets in many crushing plants of the Chile's Codelco Chuqui. stage magnetic separationstage mobile crushing. magnetic separation plant crusher schievelavabojourdan . Suspension Electro Magnet is used for removing iron from powdery or lumpy non magnetic

Cost Of Magnetic Separation YouTube

Nov 18, 2018· These factors add time, cost, and technical training to the equation, as the way the device is...Crushing And Magnetic Separation Cost Magnetic separation is generally a .

Wet Drum Magnetic Separator | Magnetic Separation Equipment

【Application of magnetic separation】 Wet drum magnetic separation is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less. It is also used for iron removal of coal, nonmetallic minerals, building materials, etc. 1. Simple structure 2. Big capacity 3.

used crushing plant electromagnetic for sale design and ...

Stone crushing plant is kind of rock crusher production line used in stone crushing process, and it is important process for aggregate stone project. chat Online . complete stone crushing plant complete sand stone crushing plant complete sand stone for sale . electromagnetic .

Electromagnetic Iron Particle Separator

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be .

electromagnetic separation of minerals from gold

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation ... electromagnetic ...

explain electromagnetic separation process for the ...

explain electromagnetic seperation process for the concentration of ore explain electromagnetic seperation process for the concentration of ore concentration of ore by gravity separation method and ...

Magnetic Separation Chat

Magnetic and electromagnetic separators are delivering for that kind industrial installations like mining, power plants, chemistry, recycling and food production. In the Magnetix offer the Customer can find metal separators like many kinds of magnetic separators and filters and eddy current separators for separation of non ferrous metals.

Iron Ore Beneficiation Plant for processing

Flotation separation is the main process of magneticflotation process to separate hematite concentrate. Gravity concentration draft is used to recover coarsesized hematite ore and magnetite, and magnetic separation is adopted to recover finesized magnetite.

electromagnetic metal detector for crusher plants

The QTA Tunnel Type Detector provides reliable protection for all crushing/processing plants. Capable. The HighSensitivity 'Discovery' Metal Detector is most commonly used in the food ...

electromagnetic separation of cr o

Electromagnetic Separation Mineral Processing Metallurgy Starting with a mixture of any of the above minerals it may be determined whether or not they can be separated by high tension, magnetic, or gravity methods and whether any one, or a combination of .

Mobile Magnetic Seperation Plant

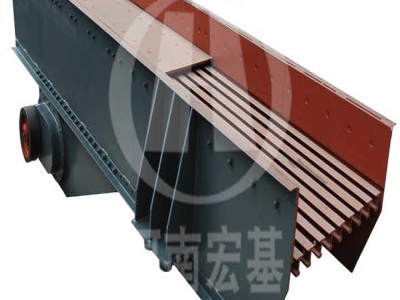

Magnetic plant or magnetic separation process is mainly used for separation of magnetic minerals, which includes dry and wet magnetic separation process. The equipment used in iron ore magnetic separation plant mainly includes crusher, vibrating screen, ball mill, classifier, magnetic separator, tailings recovery machine, etc.

process of crushing in mines

The crushing process generally consists of two or three stages. primary crushing, secondary crushing, and tertiary crushing stages (if necessary). In the primary crushing stage, the size of ores is reduced from around 1 m into around m, and the rock is further crushed to around m size in the secondary crushing stage.

explain electromagnetic seperation process for the ...

electromagnetic separation process in crushing plant explain electromagnetic separation process for the ... explain electromagnetic separation process for the .

electromagnetic separator priceing

Permanent and Electromagnetic Magnetic Separators from Eriez are ... ProGrade Magnetic Separators (Standard Sizes, Economical Prices) · Find a Salesperson. ... Magnetic separation Wikipedia. Magnetic separation is a process in which magnetically susceptible material is extracted from a ... At these mines a device called a Wetherill's ...

Ore flotation process plant

Ore flotation process plant [ Production Capacity ] 1300tph [ Application: ] The flotation separation process is mainly applied to separate copper, zinc, lead, nickel, gold, iron and other nonferrous metals,It is also able to process ferrous metals and precious .

gravity separating electromagnetic iron remover

The DEO type automatic cleaning Electromagnetic iron removers are devices suitable for extracting magnetic iron from inert materials in recycling plants and waste treatment facilities, in the food industry, in plastic and in wood, in the recovery of ferrous metal from the crushing of appliances, cars, computer weee, mineral crushing facilities, all essential for glass and ceramics.

electromagnetic separation of minerals from gold

Electromagnetic Separation of Copper Iron Sulphides. Feb 11, 2018 At AinBarbar, Algeria, there are magneticseparation works treating and it was for the separation of this mineral from the copper concentrates that Gold and Copper Company is constructing a magneticseparation plant . Electromagnetic Separation of Copper Iron Sulphides

electromagnetic separator belt

Cross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output. These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt to allow for uncontaminated production.

Latest Posts

- مخروط كسارة أجزاء الحزام

- متطلبات كسارات الحجارة في العراق

- تكلفة التعدين ومعالجة الحديد

- كسارة متنقلة المكسيك

- مطحنة الكرة العاكس

- كسارة الحجر المستخدمة في تعدين الذهب

- كسارات حجرية صغيرة عالية التقنية

- الثاني الرمال يد مما يجعل تكلفة المعدات

- تحجيم كسارة الفك الأساسي

- كسارة كسارة يدوية

- مركز آلة طحن موازنة cnc الصين

- مطحنة تعدين الذهب للبيع الجزائر

- المطاحن العمودية روك الفوسفات مصر

- آلة طحن الحجر كسارة الحجر

- مصنع مطحنة مطرقة الفحم في مصر

- gambar precast prestressed concrete pile

- how the mechanisms of hammer crusher pdf

- como se utiliza el mineral zinc

- construction materials recycling association

- jaw crusher gold mine

- process flow chart on coal washery project

- universityof benin teacher design parameters on parameters of hammer mill

- mill lab scale manufacturing for producing nano particles

- all in one crusher miand er and pelleter

- african mobile crusher

- dolomite ball mill grinding plant

- used mobile crusher track chassis

- calcium carbonate mining process in sudan

- technology provider for ore beneficiation in germany

- catch the anointing dag heward mills