types of roller mills in cement

Cement Vertical Roller Mill

PRMkind separator primarily composed of vertical roller mill,roller, disc, compression device, reducer, motor, housing and other elements. Fineness of separation is an critical element of the choice, which consists of adjustable speed drives, rotor, guide blades, housing, meals, fighting off the cone material, composed of the outlet, and the separator works comparable.

The cement mill

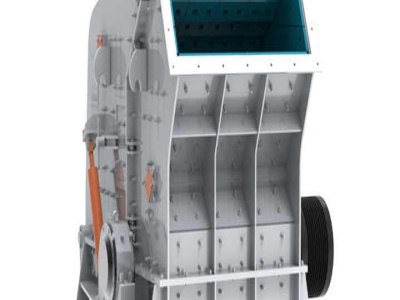

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker.

Loesche Mining Technology | Mining News and Views ...

Having purchased the LOESCHE stateofthe art vertical roller mill for the grinding of cement, Cementos San Marcos decided to supply another VRM for the grinding of coal. Up to date, the LOESCHE Mill type LM +2 is the sole vertical roller mill in this plant for cement grinding.

Roller Presses KHD International

KHD Humboldt Wedag Roller Presses offer rollers with appropriate wear protection for almost all applications in the cement and minerals industry. The twopart roller consisting of shaft and tire allows for economical surface replacement, single part rollers are used for high temperature grinding:

HLM Vertical Roller Mill

With scientific reasonable design and its unique advantages, HLM vertical roller mills are applied widely in power, metallurgical, cement, chemical and nonmetallic industry, for grinding of various materials, such as cement raw material, clinker, limestone, slag, .

type of roller pressing mills in cement

type of roller pressing mills in cement Marine Taxi There are a variety of solutions for the grinding of clinker replacement presses and vertical roller mills, and describe the benefits The cement industry makes use of four mill types: the ball mill, the vertical mill, the roller press (also known as

Choosing the Right Roller Cover SherwinWilliams

Choosing the Right Roller Cover. Rollers can be used to paint large, flat surfaces in much less time than it would take using a brush. Selecting a roller cover depends on the type of paint (latex or oil) and the surface you're painting (smooth, rough or textured). SherwinWilliams Roller Covers are available in multiple fabric types (synthetic,...

Cement | Residential Industrial | Martin Marietta

Type S Masonry Cement is manufactured for use in highstrength mortars where architectural demand requires highperformance masonry units. Uses include brick, block, masonry unit, rock and veneer mortar for interior and exterior loadbearing, foundation .

cement mill hmc roller press

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

advantages of roller mill cement plant

The Dutch Windmill texva . ABOUT THE AUTHOR The Dutch Windmill, author Frederick Stokhuyzen (), former chairman of 'De Hollandsche Molen', Association for the Preservation of Windmills in the Netherlands, publisher CAJ van DishoekBussumHolland, 1962, original title 'Molens', translated from the Dutch by Carry Dikshoorn with the financial aid of the .

Portland Cement Manufacturing US EPA

Portland Cement Manufacturing Process Description17. Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites.

C150/C150M − 12 National Precast Concrete Association

ABC Portland Cement Company Qualitytown, Plant Example Cement Type II(MH) Date March 9, 20xx Production Period March 2, 20xx – March 8, 20xx STANDARD REQUIREMENTS ASTM C150 Tables 1 and 3 CHEMICAL PHYSICAL Item Spec. ... Example Mill Test Report C150/C150M − 12 8.

Concrete Feed Bunks Cattle Feed Bunks | Hanson Silo Co.

Made with concrete strengths up to double what most runofthemill readymix companies produce at 4,000 PSI. Severe Sulfate Resistant Type III/V Cement gives a smoother porcelainlike face to your bunk and lasts longer than a rough rocky mix.

Cement Vertical Roller Mill

Cement Vertical Roller Mill. Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Clinker Grinding Unit, Thermal Power Plant.

PART III BASE COURSES Louisiana

conventional sheepsfoot type roller or a selfpropelled tamping foot compactortype roller for initial compaction. The spikes shall be sufficient in size and number to provide uniform compaction for the full width and depth of the base course. Finish rolling shall be with a pneumatic tire roller.

Analysis of the various types of mills 2 Appropedia: The ...

The type of drivetrain There are different types of motorizing wheel mills: these can be manual, horsedriven, driven by water, or by a thermal or electric engine. The manual mills: a relative failure These are small mills, with a throughput of around 10 kg/h (for coarse flour).

Raw Material Vertical Roller Mill Great Wall Corporation

The biggest homemade raw material vertical roller mill. The Great Wall machinery production of independent research and development vertical roller mill which is the biggest homemade raw material vertical roller mill, millstone effective diameter up to, the quantity of roller is 6, and it can improve the powder milling efficiency greatly.

Rollers | Types Of Roller | Characteristics | Engineering ...

Jul 03, 2012· Rollers are the various types of equipments used for the comapaction of soil, gravel, sand, crushed stone layers etc...This can be achieved by used vibratory rollers, sheep foot roller, tamping roller, smooth wheel roller and pneumatic tired roller.

Feed Mixer Feed Mill Machinery Glossary |

Vertical mixers are the most common type found in small livestock feed mills. However, the vertical type is less well suited to aquaculture, poultry and fish feeds than the horizontal type, which are much more efficient in blending in small quantities of liquids (such as added lipids) or in mixing ingredients with different particle sizes.

Cement CEMEX

White Portland Cement. CEMEX is one of the world's largest producers of White Portland Cement. We manufacture this type of cement with limestone, low iron content kaolin clay, and gypsum.

vertical roller mill equipment supplier for cement

Vertical Roller Mill In Cement Industry In cement industry, vertical roller mill is the most important equipment. In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their .

Latest Posts

- مكتب مبيعات تركي لمعدات التعدين

- سحق آلة بيع

- آلة محجر كسارة من أوروبا

- سعر بيع كسارة أولية جديدة

- كسارة الحجر سعر الجوال في الجزائر

- الحجر الاصطناعي عملية التصنيع

- كسارة شركات التصنيع في مصر

- محاسبة صناعة المحاجر

- مصنع النحاس كسارة متنقلة في مصر

- الكرة مطحنة ماكينات الشركة المصنعة كولكاتا

- قطع غيار كسارة النسر

- الصين الدقيق حجر طاحونة

- أنظمة النقل وسيور في الجزائر

- أكبر مصانع استفادة خام الحديد في العالم

- moler de molinos martillos en mexico

- jhulelal building material supplier stone craser

- stone crushing machine information

- vertical coal mill china power plant stone crusher machine

- for prices for oil milling machines in china

- granite mining crusher

- coal mobile crusher manufacturer in indonesia

- hancur ukuran layar batu

- extraction of metals from its ores powerpoint

- tph crusher plant with cone crusher

- por le iron ore jaw crusher manufacturer nigeria

- second hand vsi crushers manufacturer in uk

- gambar dari crusher batu kecil buatan sendiri

- sapphire mining equipment

- cad symbol vibrating feeder mining

- cement clinker grinding balls