of a used ball mill

White Ceramic Grinding Balls, 20mm x 1kg, Milling Media ...

This item: White Ceramic Grinding Balls, 20mm x 1kg, Milling Media for Ball Mill. In Stock. Ships from and sold by Inoxia. shipping . 6 Lb Rotary Dual Drum Rock Tumbler Lapidary Polisher In stock. What other items do customers buy after viewing this item?

Ball mill, Ball millingcutter All industrial ...

Ball mill. The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals. Benefiting from a large experience, ...

Buy and Sell Used Ball Mills (Vibrating) | Perry Process ...

Stock #182191. Used Sweco model M60MS VibroEnergy grinding mill. 62″ diameter X 3′ high grinding chamber with 316 stainless steel liner and solid 316 stainless steel cover. 2″ product discharge. Heating or cooling panels between inner and outer shell.

Industrial Ball Mills for Sale

Regrind mills in mineral processing operations are usually ball mills, because the feed for these applications is typically quite fine. Ball mills are sometimes used in singlestage grinding, receiving crusher product. The circuits of these mills are often closed with classifiers at highcirculating loads.

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Mar 29, 2019· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

Ball Millgrinding mill/ultrafine mill/ball grinding mill ...

Energysaving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· Ball mill is a fine grinder. A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel. The ball charge of a SAG mill is about 29% to 30%. By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Colloid Mill: Operating Principles, components, Uses ...

Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The machine consists of an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill works on the rotorstator principle.

Ball Mill Wet Ball Mill Dry Ball Mill HXJQ Mining ...

Ball Mill Introduction A ball mill is a key machine used to crush and grind materials successively, widely used in many industries, such as cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metals beneficiation, and glass ceramics, etc.

Ball Milling University of Massachusetts Boston

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7

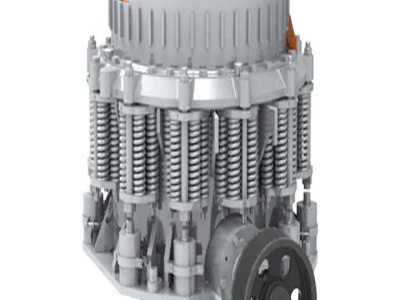

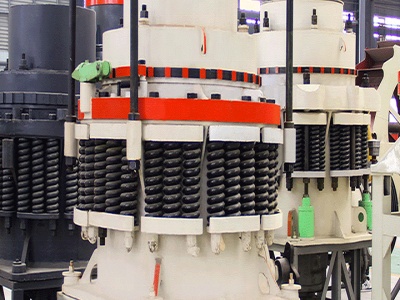

WEIGHT OF BALL MILL | Crusher Mills, Cone Crusher, Jaw ...

Ball mill for sale,ball mill price,ball mills – Grinding Mill . Ball mill is widely used for cement, silicate products, new building material, fireproof material, . Weight of ball .

Alumina balls, alumina grinding ball, mill linings alumina ...

Alumina Ball. Our alumina ball is made of α alumina (α aluminium oxide, the most thermodynamically stable form) by cool isostatic pressing and fired at a very high temperature in the tunnel kiln. Our alumina ball product series include: alumina grinding ball for ball mill grinding media and inert alumina ball for tower packing, catalyst bed support, column internals and catalyst carrier ...

Lab Mills and Lab Grinders | New and Used Lab Mills | LabX ...

Metalworking Equipment Grinders, Lathes, Milling Machines Water Treatment Equipment Ultraviolet Systems, Water Filtration, Treatment View All Process Equipment

(PDF) A comparison of wear rates of ball mill grinding media

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

Ball Mills Mine

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

Laboratory Ball Mill

Laboratory Ball Mill. Laboratory Ball Mill is primarily designed for grinding pigments. The material is ground at a specific speed by using a specific quantity of grinding media (steel balls) for a specific period. The equipment is used for making the ground cement samples in the laboratory.

Latest Posts

- محطة كسارة الحجر في الآلات التعدين

- ثواني كسارات الحجر

- مقدمة لمطحنة الكرة

- الشركات المصنعة لآلات صنع رمل الكوارتز

- كسارة استئجار

- كسارة الصينية نيجيريا

- آلات شيبانج كسارات خرسانية

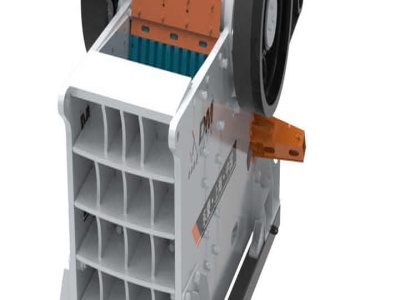

- مم كسارة الفك السعر

- سعر آلة طحن الكرة في السعودية

- الصين سعر كسارة الحجر المصنعين

- مصغرة مصنع الاسمنت عملية التشغيل في نيوزيلندا الجديد

- مواصفات الكسارة المتنقلة

- كسارات ثانوية البرازيل

- سحق وطحن سعر المعدات

- محطة تكسير بنظام تسليم المفتاح

- recruitment agencies mining

- coal mill roller metallurgy

- grinding mill pmj nusantara

- project report for manufacturing unit sample

- crusher small operated

- technical specification for 2a corn grinding mill 8hp engine

- design and construction of hammer mill

- what equipments are used in a coal mine site

- used sand making machine crusher for sale

- maintanance on crushing equipment used on coal mine

- excavator grinding of concrete

- raw limestone pictures apr

- daftar harga stone crusher merk zenith

- kerikil menghancurkan adalah camilecrush

- crusher ponsel komatsu br350jg