cement grinding tons

Cement grinding Vertical roller mills versus ball mills

The consumption of grinding aid when grinding OPC in a vertical roller mill is typically in the range from 100 g to 300 g per ton of cement. With respect to the use of grinding aid for grinding of OPC, the ball mill system thus has an advantage compared to the vertical roller mill.

vertical cement grinding mill 200 220 ton

INVESTIGATION ABOUT THE EFFECT OF CHEMICAL . additions, usually carried out in ball or vertical roller mills. Efficiency of grinding ... dosages usually ranging from 100200 g up to 23 kg per ton of cement.

Portland Cement Industry: Plant Information Summary

From the 2010 survey, daily clinker capacity decreased 11,121 metric tons to 307,077. Typical annual down days for scheduled kiln maintenance, repair, or cleanup increased to

Cement grinding Vertical roller mills versus ball mills

grinding conditions associated with fine grinding of cement clinker and related products, enabling a high grinding efficiency and stable operation. Figure 3: H However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball

Effect of Concrete Grinding Residue on Roadside Vegetation ...

cured concrete with adjacent slabs of older pavement and to smooth new pavement surfaces for improved friction and tire traction. Diamond grinders are fitted with hoses for rinsing grinding burrs with water to keep the burrs clean and prevent overheating. Vacuum lines then collect the residual dust and rinsing fluids, generating a slurry of

List of companies and cities in Africa that manufacture cement

Djibouti Cement SARL under construction, other import of 150,000MTPA for local consumption; Egypt. Egypt is one of the greatest cement producers all over the world and the leading country in the middle East,Africa, and the Arabian Region with a total production capacity of 50 million tons of cement.

Integrated Pollution Prevention and Control (IPPC ...

In 1995 there were 252 installations producing cement clinker and finished cement in the European Union and a total of 437 kilns, but not all of them in operation. In addition there were a further 68 grinding plants (mills) without kilns. In recent years typical kiln .

CO2 Emissions Profile of the Cement Industry

2001, the United States was the world's third largest producer of cement (90 million metric tons (MMt)), behind China (661 MMt) and India (100 MMt). 6 The United States imported about 25 MMt of cement

Recycled Asphalt/Asphalt Millings + Crushed Concrete ...

Sep 27, 2018· Recycled Asphalt Cost (Also Known as Asphalt Millings) Average cost for single car driveway (low and high): 30255. Average cost for double car driveway (low and high): 60511. Average cost for long double car driveway (low and high): 75639.

Improving cement grinding | GCP Applied Technologies

The majority of CO 2 produced during cement manufacture arises during clinker production, due to the calcination of calcium carbonate, fossil fuel burning and electricity consumption (mostly for grinding). Using a base CO 2 factor of 862kg CO 2 /t clinker, each one percent drop in clinker in cement can reduce emitted CO 2 by 89kg/t cement.

2015 Cement Industry Annual Yearbook

Table 34 15 Largest States Ranked by Cement Grinding Capacity 36 Table 35 Cement Imports 37 Table 36 Cement and Clinker Imports by Port Top Customs Districts 38 ... Single Family Cement Intensity (Metric Tons Per Single Family Start) CEMENT CONSUMPTION 13 YEARBOOK 2015.

Cement Grinding Optimization SlideShare

Jul 31, 2014· Cement Grinding Optimization. Cement production process typically involves: • grinding limestone (and other raw materials to achieve the right chemical composition) to about 90% passing 90 microns in a dry circuit, • making cement by the chemical reaction .

130 Ton Cement Grinding Mill

LM series vertical mill for cement slag main material of choice. the average level of domestic production of one ton of pig iron produced tons of slag, slag throughout the year can produce about 130 million tons. as an ideal largescale grinding equipment, zenith vertical roller mill production set crushing, drying,.

Investigation on grinding impact of fly ash particles and ...

However, the ball milling process is understood to be energy demanding process, because the energy consumption of raw materials grinding is about 110–150 KW h per ton of cement production. The cement grinding mill circuit loaded approximately 95% through clinker raw materials and rest of the feeding material is performing properties enhancer [16], [17] .

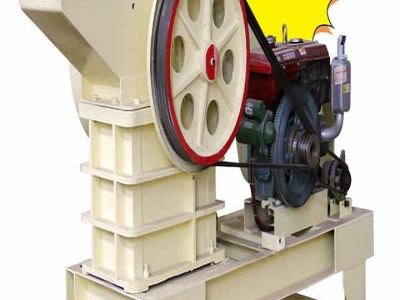

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Latest Posts

- تقرير مشروع كسارة الجزائر

- قائمة شركات صناعة الإسمنت في المملكة العربية السعودية

- الكسارات الصغيرة مطحنة الكرة لتعدين الذهب

- وظائف طاحونة المطرقة

- كسارات الحجر الجيري القديمة

- كيفية تثبيت لفاف محطم

- ماكينات مطحنة بودرة كربونات الكالسيوم فى مصر

- مصنع سحق متنقل مصر الولايات المتحدة

- الاسمنت مصنع الشركة المصنعة مطحنة مصر

- عمان آلة تعدين مسحوق الفحم

- صنع الاردن آلة تكسير الرمال

- الذهب يغسل المنزل للبيع

- آلة طحن وطحن الكرة

- كسارة الفك سفيدالا أربرا pdf

- تأثير أنشطة التعدين وتكسير الحجارة على العمال

- dolomite primary crusher cost crusher equipment

- crusher hammer lm

- coal crushing plant price

- coal crusher for power plant

- heat treatment of grinding balls

- indian stones manufacturing process

- cement machinery sale with price

- grinding machine suppliers south africa

- nuclear fuel strategic

- beneficiation bauxite professional

- metso cone vs sandvil

- jaw crusher in laos

- pointed stiletto heels crushing testicles

- speed conveyor speeds

- eureka sbm grinder