primary gyratory crusher

Gyratory Crusher, HGT Hydraulic Gyratory Crusher is a ...

HGT Hydraulic Gyratory Crusher makes the market of Liming Heavy Industry in primary crushing bigger, and it is known as an intelligent crushing equipment. The product not only adopts super beam design in structure, but also equips oil proof device and positive pressure dust prevention device.

SMX Series Gyratory Crusher SANME

Gyratory crusher is a largescale crushing machine used for primary crushing of various hard ores or rocks, the feed material will be compressed, broken and bended through gyrating movement of breaking head within the chamber.

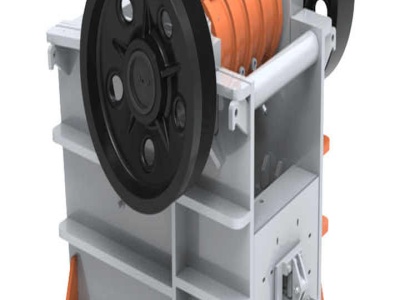

Jaw Crusher VS Gyratory Crusher JXSCMACHINE

Apr 20, 2019· The gyratory crusher is mainly used for coarse crushing of various hard material in the primary crushing stage, but it is not suitable for crushing viscous ore. Jaw crusher can crush high moisture, viscous ore, and not easily blocked.

Tenova Takraf sets another spares record ...

Jan 25, 2016· Tenova Takraf sets another spares record servicing a Sishen Primary Gyratory Crusher. The crusher is supported by Tenova TAKRAF Africa's regional office in the Northern Cape, which, staffed by experienced technical personnel and positioned close to the client base in that region, is able to provide fast response aftermarket services,...

Primary gyratory stations Metso Automation PDF ...

Primary gyratory crushers Metso superior® primary gyratory – the first step in highcapacity inpit crushing The heart of a crushing pit Years of experience and thousands of primary gyratory installations combine to create the best gyratory the industry has to offer.

Improving shutdown times with primary gyratory relining ...

Shutting down a primary gyratory crusher for relining requires careful planning. The entire shutdown process—from cleaning out the pit to the final relining steps—can take days and, in some ...

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

concasseur Metso 6089 MKII | worldcrushers

Sep 02, 2013· Nordberg SUPERIOR ? 60110E primary gyratory – Metso Corporation. Metso's SUPERIOR ? 60110E primary gyratory crusher provides a redesigned Spider, a onepiece bottom shell and a new rim liner retention system.

Superior™ MKIII 60110 primary gyratory crusher Metso

Metso's product family of primary gyratory crushers is called Superior™ MKIII primary gyratory crushers. The "MKIII" stands for the third generation of the Superior™ primary gyratory crushers Metso has developed during over 100 years in designing and manufacturing crushers.

gyratory primary crushers, mobile double roller coal crusher

aggregate crushing strength, stone crusher machine into fine sand, jaw crusher popular supplier of company, output gradation grinding mills, mining equipments mobile crusher, chinese manufacturer of vertical roller mill, owning operating cost for crushing plant, mobile construction material crusher

Gyratory Crusher Reliability Program GlobalPAM

Jan 03, 2019· Primary Gyratory Crusher Reliability Program The objective of the gyratory crusher reliability program is as follows: Mapping the crusher mantle and concaves for trending, thickness, etc.

The Metso 4265 Gyratory Crusher YouTube

May 20, 2016· A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of ...

Gyratory Crusher Reliability Program GlobalPAM

Jan 03, 2019· The objective of the gyratory crusher reliability program is as follows: Mapping the crusher mantle and concaves for trending, thickness, etc. To ensure integrity of the mainshaft and lifting eyes for the primary crushers

Primary Gyratory Parts | Gyratory Crusher Parts | CMS Cepcor

Home » Crusher Parts » Primary Gyratory Parts. Primary Gyratory Parts by CMS Cepcor® The CMS Cepcor® product range of precision machined replacement parts to suit primary gyratory crushers includes complete mainshaft assemblies, mainshafts, cores, spider assemblies, spider bushings, spider seals, top shell assemblies, bottom shell assemblies, eccentric bushings, shell bushings, .

gyratory crusher

Crusher Wikipedia. A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening.

Metso SUPERIOR® gyratory crushers

Metso SUPERIOR® gyratory crushers Metso SUPERIOR® primary gyratory – the irst step in highcapacity crushing Years of experience and thousands of primary gyratory installations combine to create the best gyratory the industry has to ofer.

Peak performance from Metso's new Superior MKIII primary ...

Peak performance from Metso's new Superior MKIII primary gyratory crusher. The Metso Superior MKIII provides a significant performance leap in gyratory crushing. Based on Metso's industry leading crushing technology, the MKIII is the first highspeed primary gyratory crusher to deliver up to 30% higher capacity and 70% lower downtime in a comminution circuit.

Primary Gyratory Crushers Mining

Primary Gyratory Crushers Our Sandvik primary gyratory crushers are robust machines engineered to deliver the utmost availability. Combining wellproven design with advanced technology, the crushers are ideal for tackling large boulders with a large feed opening and a grooved mantle, an optimized nip angle, and selftightening concave liners for maximized capacity, output and machine life.

Gyratory Crushers: Misunderstood Maintenance AggMan

Mar 01, 2013· Most gyratory crushers can be supplied with mantles of different diameters, such as the standard shape mantle, an oversize mantle, and possibly even a doubleoversize mantle. When performing mantle or concave replacement maintenance, it is critically important to understand when each mantle should or should not be used.

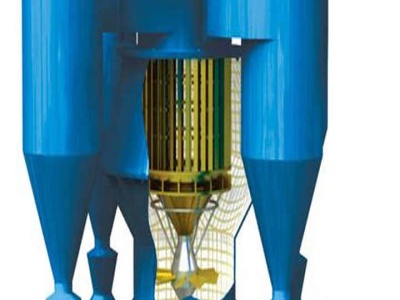

Crusher NDT Program GlobalPAM

Jan 02, 2019· The Crusher NDT Program is for HVC primary gyratory crusher components including the main shaft, large and small castings, pinion shaft assembly, adjustment and clamping rings, main frame, and hydroset. Suggested Inspection components: Main Shaft Ultrasonic Insitu Inspection; checking for cracking from inside out and surface.

GC Series Gyratory Crusher Luoyang Dahua

GC Series Gyratory Crusher is a new generation primary crushing and continuous operation equipment for the ultralarge mining and quarrying project.

Liner wear and performance investigation of primary ...

Liner wear and performance investigation of primary gyratory crushers Article in Minerals Engineering 17(11): · November 2004 with 178 Reads DOI: /

Tenova Takraf sets another spares record ...

Jan 25, 2016· One of the largest spares to be ordered and manufactured by Tenova TAKRAF Africa, a top and bottom shell for a 60/109 primary gyratory crusher, .

Latest Posts

- عملية رسم تخطيطي لمخطط كسارة الخبث

- سعر كسارة مخروطية مركبة

- تجار محطة كسارة

- ثمن كسارة مخروطية في weden

- سعر خلاطة الاسمنت في لاغوس السودان

- كم هي تكلفة لصغار الحجر الجيري كسارة

- الأجزاء الداخلية كسارة الفحم التعدين كسارة

- سؤال وجواب مصنع الاسمنت

- إطار كسارة vsiص بيع

- مصانع الاسمنت المصغرة الكبيرة مصر

- عملية صيانة نموذج مطحنة الكرة إجراء الصيانة

- معدات تعدين الذهب كاملة والأسعار

- ورقة تدفق مصنع تعدين خام الحديد

- محطة التكسير والغربلة الرطبة المتنقلة

- كسارة فكية للبيع كولومبيا البريطانية

- menghancurkan perusahaan afrika selatan

- gulin cone crusher sale price crusher machine for sale

- silver processed in ball mill

- sand crusher manufacturer companies

- largest iron sand dry magnetic separator

- quarry stone cutting machine south africa

- rubber conveyor pvg

- wire point grinding machine

- specification of pulverizer

- stone crushers plant in and around nairobi

- coarse grinding stone for dremel

- cattle mineral feeders

- jaw crusher x cm pricechina

- compare prices on carbide die grinder bits oct

- harga tanaman menghancurkan ponsel untuk batu