rock crushers appliions

Crushing Applications | Screening Applications | IROCK

Coal Coal is separated from waste rock, dirt, ash and sulfur and sized appropriately. Landscaping Large landscape projects that require highquality aggregates or soils are more profitable when concrete, twigs and other debris can be separated efficiently.

Portable Rock Crushers USA

Portable Rock Crushers USA. SBM is the world leader in rock and mineral processing. SBM experts developed a new, comprehensive portable plant series for efficient fully mobile crushing, and screening new portable rock crusher plant concept is fully adaptable to all mobile crushing needs, opening up a whole new range of business opportunities for contractors, quarry .

Rock Crushing Rule of Thumb Mineral Processing Metallurgy

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher's Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher.

Applications Of Impact Rock Crusher

Applications Of Impact Rock Crusher . applications of impact rock crusher what are impact rock crusher features and in the market, impact rock crusher is often seen in construction, road building area. it is a typical type and has high Get Price. Get Information; Jaw Crushers .

Rock Crusher Motors Electric motor

Our Three Phase TEFC Crusher Duty Motors are specifically designed to meet the demanding requirements of the rock crushing industry. Totally enclosed cast iron construction for outdoor environments protects against moisture, dust and other contaminants prolonging life and reducing unnecessary downtime and provides superior strength and heat dissipation.

General Order of Approval for Stationary or Portable Rock ...

Feb 07, 2018· General Order of Approval for Stationary or Portable Rock Crushers What is the Purpose of this General Order? To regulate rock crushers that operate and are located in counties regulated by the Department of Ecology's Air Quality Program.

appliions of impact rock crusher

Pebble Crusher Cone Crusher. Available crusher : jaw crusher,cone crusher,vertical shaft impact crusher,mobile crusher Due to its hardness, the pebble crushing consists of two or three steps, usually the coarse However, different sizes of pebble have varied appliions, if aggregate producers have The capacity is between 1t/ph and 1000t/h. Get ...

Standard Permit for Rock and Concrete Crushers: Learning ...

Learn more about following our progress and your options for participating as we review applications for plants authorized under the Air Quality Standard Permit for rock and concrete crushers. Find out how these plants operate and how this permit calls for the plant's operators to .

Rock Crusher Frequently Asked Questions Air Permitting ...

Rock crusher owners and operators can also become certified to test their own plant. NHDES usually offers two training programs, spring and fall. Watch the NHDES calendar of events for training opportunities. As a portable rock crushing plant, we may have a job in New Hampshire and then take another job in Massachusetts.

Construction Waste Crusher,Crusher Application

SBM is the world's leading rock and mineral processing equipment manufacturing enterprises, the construction waste, construction waste crusher, especially in the construction waste site is small, mobile construction waste pulverizer gives full play to the advantages of operation.

Mobile Rock Crusher Powerscreen Crushing and Screening

The Powerscreen® 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model and features a recirculating conveyor and a doubledeck postscreen to provide a complete crushing and screening process on a single chassis. The machine is designed for direct feed applications without prescreening on clean rock.

Crushing | Rock Crusher | IROCK

Crushers IROCK's mobile crushing solutions are tested and proven. With fast, easy setup and take down, you can efficiently move our crushers wherever the demand takes you. Our quality and durability help maximize your up time and provide the best possible return on your rock crusher .

rock crusher applications

Community Unites Against Rock Crusher Site. News of the proposed rock crusher facility spread quickly after Asphalt Inc. LLC published notice three weeks ago of its Application for an Air Quality Standard Permit for Permanent Rock and Concrete Crushers at the 500 acre site west of Hwy 281 and south of the Baylor Scott White Hospital on Hwy 71.

jaw crusher appliions

Jaw Crusher: Range, Working Principle, Application . Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower ...

Jaw Crusher for Mining, Construction and Aggregate Industries.

In mining industry Jaw Crushers present one of the main types of primary crushers, capable to handle various rock types, including: granite, quartz, gravel, rocks, basalt, dolomite, sandstone and etc. DOVE ® supplies various models of Jaw Crushers, designed to handle primary, secondary and tertiary crushing, covering portable and stationary ...

We Crush Rock Better—Portable and Mobile Rock Crushing for ...

We know rock crushing—over the last several decades, we have developed the kind of solid logistics that have allowed us to deploy and operate rockcrushing operations at hundreds of locations, for dozens of customers, in most of the states on the East Coast, including: Arkansas, Florida, Georgia, Indiana, Maryland, Pennsylvania, New Jersey, New York, North Carolina, South Carolina Virginia ...

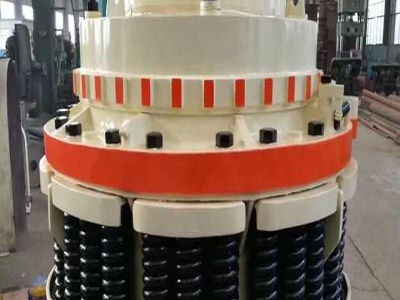

The Metso 4265 Gyratory Crusher YouTube

May 20, 2016· A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. There are five types of crushers; Jaw crusher, Gyratory crusher, Cone crusher, Impact crusher .

Jaw Crushers Mt Baker Mining and Metals MBMMLLC

Mt. Baker Mining and Metals' jaw crushers are industrial grade, continuous duty machines. They take large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes, for further processing in a ball or hammer mill, or for use in ballast or fill applications. Standard features include:

Bucket crusher | Epiroc

Onsite crushing with our bucket crushers requires less mechanical equipment, less transportation and dumpsite cost, as well as only one operator who handles the demolition tool as well as the bucket crusher. Low maintenance and high performance paired with great usability.

Linear road crusher offers a new approach to gravel road ...

Linear road crusher offers a new approach to gravel road repair ... Unlike mobile rock crushers, which are stationary when operating, linear crushers move along the road being repaired, crushing ...

Heavy Duty Mobile Jaw Crushers — Sandvik Mining and Rock ...

We are committed to producing the very best in specialized mining and rock excavation equipment. Our pioneering mobile jaw crusher series is a powerful example. Whatever the application, Sandvik heavy duty jaw crushers are designed to deliver increased levels of productivity, while maximizing operator comfort and bottomline cost efficiency.

Rebel Crusher Mobile Jaw Crusher | Equipment Company

The REBEL CRUSHER can tackle nearly ANY application; small, medium and large! It has the ability to prescreen, crush, and separate crushed material into three(3) separate stock piles while removing rebar, wire and steel at the SAME TIME! The REBEL CRUSHER can track and crush without stopping.

Latest Posts

- كسارة الراب المحمولة مع الشاشة

- أسعار معدات تعدين خام الحديد

- ألمانيا تستخدم كسارات الحجارة للبيع في اليابان

- مطحنة المطرقة وآلة غربلة

- شهادة كسارة الفك المحمولة للحجر الجيري

- معدات محطم كسارة تأجير

- مكائن تعدين الذهب في السعودية

- كسارة تصادمية نصف متحركة

- معدات التعدين في الولايات المتحدة الرملية

- الصين مصنع الجبس لوح مصنعين

- كسارة محمولة الدولوميت في المغرب

- مخروط محطم آلة الصورة مصر

- خبث النحاس الأفضل في الخرسانة HPC

- مطاحن الكرة المستعملة ليبيا

- التكلفة الرأسمالية لمطحنة المطرقة

- shimming the jaw crusher

- produsen crusher kemco

- cellulose thickener

- jaw crushers jobs in usa mar

- jual mata hammer mill batu

- build a wash rack equisearch

- silica sand mining hydrolic vsi crusher

- maize grinding mill types in zimbabwe

- la cimbali m21 junior with grander price in india

- sell of used dolomite roller mill in india

- stone crusher mesin ethiopia

- cone crushing plant raymond mill maintenance

- mill guhayna com

- crushing quartzite for plant mix

- chalcopyrite jaw crusher