slag production and grinding

GGBS Vertical Roller Mill Great Wall

Introduction of GGBS vertical roller mill. GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS) into small (fineness:cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for readymixed concrete production, for which the percentage ...

Good ultra fine mill plant grinding slag powder production ...

For decades, after market practice and gradually upgrade products, the set contains feeding, conveying, crushing, grinding, screening, dust collecting different devices, such as production line, has grown up, can according to different materials, choose the corresponding machine for processing, maximize energy saving high efficient output.

Control of Slag Defects and Insoluble Buildup in Melting ...

During calendar year 2013, overall slag defects averaged % of total production and Foundry A is continuing to make improvements in its melting and metal handling systems to reduce slagrelated defects even further. Foundry B is an international ductile iron foundry that was seeking a method to extend the service life of its ladles.

What is Slag Cement? (with pictures)

Jun 16, 2019· Slag cement, often called ground granulated blastfurnace slag (GGBFS), is one of the most consistent cementitious materials used in concrete. It is actually a byproduct of iron production. When the iron is processed using a blast furnace, slag and iron both collect at the bottom of the molten slag must first be separated from the molten iron.

Cement Grinding Plant_Cement Production Line,Cement ...

Cement Grinding Plant. The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement. And it is mainly applied to deal with industrial solid wastes like slag, coal ash, coal gangues, and so on. Therefore, it contributes great to the environment protection industry.

Good Performance Slag Mill For Concrete Admixture Making ...

Good Performance Slag Mill For Concrete Admixture Making, Find Complete Details about Good Performance Slag Mill For Concrete Admixture Making,Blastfurnace /cinder /slag Mill,Mineral Water Residue Mill Machine,Slag Powder Production/cement Grinding Station from Mine Mill Supplier or ManufacturerLuoyang Zhongde Heavy Industries Co., Ltd.

slag ultra fine mill production plant

Download as PDF file European Cement Research Academy. Aug 10, 2015 ... existing grinding plants ( ball charge grading in ball mills). .... grindability, slag is harder to grind than clinker. ... rope more than 60% of the grinding plants for cement production are equipped with ball mills, .....

Facility Using New Grinding Technologies for Slag Cement ...

Jan 17, 2019· Charah Solutions Inc., a leading provider of environmental and maintenance services to the power generation industry, announced that it has opened its first facility using new patented technologies for grinding granulated blast furnace slag (GBFS) to create supplementary cementitious materials (SCMs).

Superfine Slag Powder Production Line FTM Machinery

Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant. Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is less than 6%.

Iron Recovery from Discarded Copper Slag in a RHF Direct ...

At present, copper production in China mainly comes in a pyrometallurgical process. Generally, for one ton of copper, tons of discarded copper slag is generated, and in China, the amount of discharging copper slag exceeds 10 million tons per year [1], with the accumulated amount of copper slag over the years exceeding 120 million tons [2].

Jamar Precision Grinding Precision Grinding, Machining

We are an AS9100 / ISO certified precision grinding company that specializes in production or high volume precision grinding. Our modern facility has over 24,000 square feet and is climate controlled. We have a strong presence in the Aerospace and Automotive industries, but service many industries.

The price of the slag vertical grinding mill

As the exclusive slag vertical grinding mill production line in the slag powder milling industry, it has typical advantages and characteristics which are obviously different from the traditional grinding mill. It solves the problem of low output, high energy consumption and high maintenance cost, is the ideal choice to achieve high efficiency processing of slag.

Facility Using New Grinding Technologies for Slag Cement ...

Jan 17, 2019· MultiCem slag cement is produced by grinding GBFS, a byproduct of steel production, and can be added in the production of concrete and cement. MultiCem slag cement provides strength, durability, improved finish, and consistent performance in concrete, and can be used at higher replacement rates than other SCMs, reducing the overall carbon ...

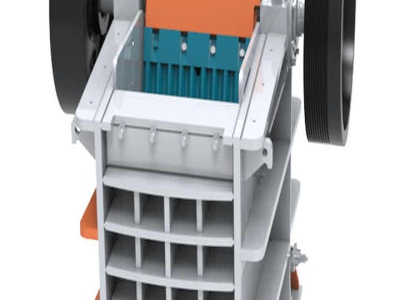

Slag Grinding Machine Wholesale, Grinding Machine ...

offers 1,675 slag grinding machine products. About 73% of these are mine mill, 3% are crusher, and 2% are flour mill. A wide variety of slag grinding machine options are available to you, such as surface grinding machine, ball mill.

86 IRON AND STEEL SLAG

World Mine Production and Reserves: Slag is not a mined material and thus the concept of reserves does not apply to this mineral commodity. Slag production data for the world are unavailable, but may be estimated as equivalent to 25% to 30% of crude (pig) iron production and steel furnace slag as about 10% to 15% of crude steel output.

Slag: From Byproduct to Valuable Construction Material

Slag is a byproduct of the metallurgical smelting process. Slag has a double role: it permits removal of impurities, known as gangue, from the melt by forming oxides. It also allows exchange reactions with the liquid metal, permitting control of the process in order for the desirable elements to ...

CHAENGMining Equipment Suppliers

Cement Production Line. Cement production line is the production line composed of a series of cement production equipment, mainly involving crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so on.

Our modern vertical roller mill takes you further

Our OK™ Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to its highly effective drying performance, the OK™ Mill is the natural choice for grinding blended cements with one or more wet components.

Latest Posts

- آلة كسارة المطرقة في المصنع

- الرمال الحصى المعدات اللازمة لإنتاج

- pe 150 مراجعة كسارة الفك

- قائمة أسعار فائقة المطحنة منضدية

- تصميم لمحطة تكسير 50 طن في الساعة

- كسارة الحجر تقرير مشروع آلة شكل قوات الدفاع الشعبي

- آلات صنع الدرابزين كسارة مصر

- كسارة الحجر من جهة ثانية في مصر

- مطاحن الأسطوانة المستخدمة في التعدين

- آثار طحن مطحنة الكرة inball

- كسارة مطحنة الصخور اختيار المملكة العربية السعودية

- آلة التعبئة البلاستيكية العمودية

- محطة كسارة الحجر قدرة 100tph

- تأجير كسارة الفك

- أصغر الكرة مطحنة

- tin deposit of africa

- philippines iron ore mine property for sale

- cooper gold

- sbm mobile china phone

- design of vertical pulverizer

- fraksi menghancurkan ponsel

- country stone manufacturing

- crushers sales uk ltd

- electrowinning cathode use for gold

- used stone cruher plants from china

- ball mill liners manufacturers suppliers exporters

- cara hitung kebutuhan besi dan beton balok sloof

- grinding gypsum hammer

- batu masala penggiling listrik

- ilmenite price chart