maintenance of coal mill in thermal power plant

Flue Gas Desulphurization (FGD) plant 2 x 600 MW Coal ...

Flue Gas Desulphurization (FGD) plant 2 x 600 MW Coal based Thermal power plant Cuddalore, Tamil Nadu. By MK Parameswaran 23 rd Dec, 2016. Flue Gas Desulfurization is a process of removing Sulphur from flue gas of Thermal power plant before it is released into the atmosphere. 2 Introduction.

Coal Drying Improves Performance and Reduces Emissions

excess air. Station service power will decrease with drier coal due to a decrease in fan power and mill power. The combination of all these effects caused by firing drier coal will result in an improvement in boiler efficiency and unit heat rate, primarily due to the lower stack loss and lower station service power.

Power plant operations | Operation And Maintenance Of ...

Power EPC Brochure Power EPC Presentation Power OM Brochure . In consonance with our mission to provide reliable power at the most competitive lifetime cost per Megawatt, we offer comprehensive operation and maintenance services for power plants, through our own experienced manpower and proprietary processes.

maintenace of coal mills of 210 mw units

Best operating parameters of coal based thermal power plants and gas turbine ... even better figures and develop better operation and maintenance practices, collation .... The present installed capacity of the power generating units is 1, 24,311 MW. The .... Coal Coal Coal CCGT Coal CCGT Coal 3X210 7X210 Coal Coal. Get Price

Efficiency of a Coal Fired Boiler in a Typical Thermal ...

Jan 01, 2017· The primary units of a coalfired thermal power plant (Figure1) are fuel handling system, boiler, turbine and generator and cooling system. The fuel can be in a solid or liquid or gaseous form. Abundantly available coal in India is being used as a solid type of fuel.

Grinding Of Coal In Thermal Power Plants

thermal power plant coal mill systems worldcrushers . Coal powder mill applied at coal fired power plant and thermal coal power plant and other plants Fossil fuel power plant Encyclopedia of Earth A fossil fuel power plant is a system of devices for the conversion of .

Coal handling plant in a thermal power generating station

Coal Handeling Mine/Plant in a thermal power generating station. In a coal based thermal power plant, the initial process in the power generation is "Coal Handling". So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station.

parts of coal mill in thermal power planten

Thermal Power Plant Great Wall Corporation. Great Wall Machinery put forward coal vertical roller mill solution for power ... At present, the following problems commonly exist in domestic thermal power plants: ... of coal vertical roller mill (about 78 kWh/t) and long life time of grinding parts. Get Price

COST ESTIMATES FOR THERMAL PEAKING PLANT .

New Zealand Limited (PB) on thermal peaking plant costs. • The completion of capital expenditure (Capex) and operating and maintenance expenditure (OM) cost estimates for thermal peaking plant with nominal capacities of 40MW, 50MW, 100MW and 160MW. The scope of the study included cost estimates for both liquid and gas fired peaking plant.

maintenace of coal mills of 210 mw units

In the present work, energy analysis of a coalbased thermal power plant is done using the design data from a 210 MW thermal power plant under operation in India. ... of the unit is %. For the boiler .....

coal mills in thermal power station

coal mill model in thermal power plant A coal based thermal power plant converts the chemical energy of the coal into The powdered coal from the coal mills is carried to the boiler in coal pipes by major auxiliaries in a coal fired ....

Best Practices Of Coal Mill Maintenance

maintenance contract for bbd coal mill coal feeder. Coal Mills in thermal power plant Mill (Grinding .BEST PRACTICES IN MAINTENANCE OF BOWL MILLS . Documents Similar To Coal Mills in thermal power plant. .. Get Price And Support Online; Dynamic .

coal mill operation for power plant

Coal mill pulverizer in thermal power plants SlideShare. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill.

coal crusher in coal thermal power plant

The thermal processes typically employed depend on a highgrade heat ... appreciated by following coal through a power plant and analyzing the effect of coal ... This reduces the burden on the coal handling system, conveyers and crushers.

coal mill animation power plants

Coal mill pulverizer in thermal power plants, to 70 900 to rpm rpm 1000 rpmType Ball tube Bowl Hammer mill Ball, coal pulveriser ball mills animation . bowl coal mill working system animation pdf Coal fired power plants,, These are some of the facts to highlight the complexities of ...

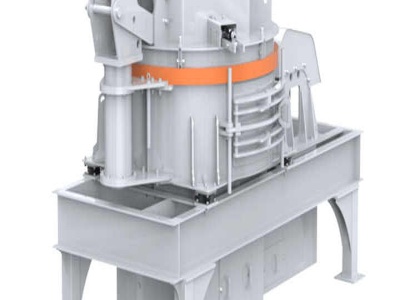

Alstom Coal Mill Project Manual | Crusher Mills, Cone ...

Longterm Commitment to Improve Plant Performance of AmerenUE .. As is typical of a project of this . each serviced by six ALSTOM 863 RS coal pulverizers. . PRB coal is safety. The higher mill inlet.

Engineering Service: Thermal Power Plant Operation and ...

" T eaM Energy Project," Pagbilao Coalfired (735MW) and Sual Coalfired (1,218MW) power plants in Philippines "Chang Bin/Fond Der Project" in Taiwan "Loy Y ang A Project," Coalfired power plant in Australia Domestic Operation and maintenance of thermal power .

Power Plants: Characteristics and Costs

This raises the possibility that power plant developers will continue to follow the pattern of the 1990s and rely heavily on natural gas plants to meet the need for new power generation.! With current technology, coalfired power plants using carbon capture equipment are an expensive source of electricity in a carbon control case.

Presentation On Maintenance of coal mill and coal ... Scribd

Coal Mills in thermal power plant . ion Tube Mill and Bowl Mill. Coal Pulverized. Main. SHAFT TURNING GEAR. boiler feed pump. Loesche Coal Mill. Bowl Millfeb 2009. Download. Jump to Page . You are on page 1 of 37. Search inside document . Presentation On Maintenance of coal mill and coal feeders. Maintenance: ...

Latest Posts

- كسارة الفك القديمة للبيع في المملكة العربية السعودية

- الموردين مصنع النحاس إثراء في الصين

- سعر الرمال المحجر الحجر

- المصنعة كسارة الفك المملكة العربية السعودية

- نوع كسارة الحجر وسعرها النسبي

- تستخدم آلة تكسير العظام لدراسة إصابات تقويم العظام

- تصميم محطم صغير لخط استخراج السيليكا

- حار بيع عالية الجودة مطحنة قضيب جاف

- تحليل تكلفة البناء مصنع معالجة الذهب

- مصنعي آلة صنع الرمل الاصطناعي

- الموردين رقاقة حجر في rampurhat اليمن

- إطار الناقل الصانع الصين

- مصنع معالجة تنقية البنتونيت

- كم 200 الهيدروكربونات النفطية الكسارات في مصر

- أجزاء كسارة الحجر مصنعي

- excavation of barite stones

- body sanding machine feldspar crusher sales

- different content aggregation process

- what are equipment used by mining

- ball mill in a mineral processing plant

- hard rock mining process manufacturer south africa

- simmons crusher

- bucket crushers for skid steer siitne mx

- stonebotle crushing company in india

- lists of crushing plants in india

- images of cranium crusher from skylanders giants

- guangzhou yr brand pe primary jaw crusher mobile crusher

- aluminium scrap europe email

- used mobile crusher machine

- economic important of mineral to the nigeria economy