use of limestone in cement production

Improvement of Concrete Sustainability and Performance ...

• Crushed limestone is fed to the mill with the clinker and gypsum • The limestone is more easily ground than the harder clinker and becomes concentrated in the finest particles • Overall fineness must be higher (for equivalent performance) Production rate is slowed Additional grinding energy used is more than offset by energy savings

use of limestone in cement production

Products involving the direct use or indirect use of limestone include cement, mortar, concrete and and lime are used to increase the fertility of soil by reducing acidity and there is much pressure on food production around the world.

PortlandLimestone Cements: History, Performance, and ...

Verifying Portland Limestone Cement Durability Holcim ASTM C595 (Type IL) or ASTM C1157 cements are tested for durability performance. Tests generally include: Fresh Hardened concrete properties Requirements are met through concrete mix design – ASTM Sulfate Resistance ASTM C1012 AlkaliSilica Reactivity ASTM C1260/1567

StateoftheArt Report on Use of Limestone in Cements at ...

portland cement, blended cement, and portlandlimestone cement similar to that used by ASTM C1157, Standard Performance Specification for Hydraulic Cement. As an example, a "GU" designation indicates that the cement is intended for general use in concrete construction. CSA

The effects of limestone aggregate on concrete properties ...

The use of limestone in the construction industry has been increasing due to benefits as aggregate. Some of these benefits include good strength, low possibility of alkalisilica reaction and the decrease in drying shrinkage in concrete. This research discusses the consumption and general characteristics of the limestone aggregate in USA and Japan.

Please join us for an informal workshop on: Portland ...

PLC Production, Specifications, Use, and Performance PLC Production, Specifications, Use, and Performance • What, why, and how of PLC • PLC experiences, documented performance • Investigating PLC "synergies" that benefit concrete strength and setting performance Overview 2 So, what is portlandlimestone cement (PLC), anyway?

How is limestone used in cement

The sedimentary rock that is used in making cement is limestone. Cement, which is used in making concrete, is a mixture of marl and lime.

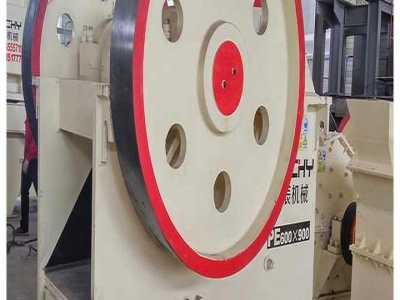

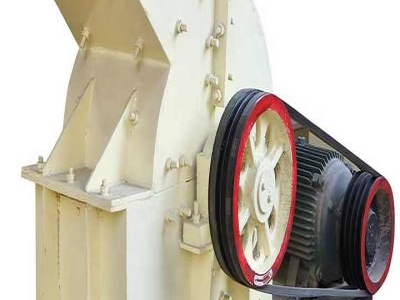

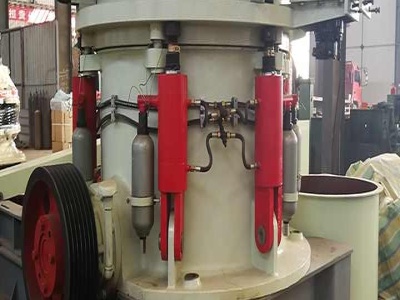

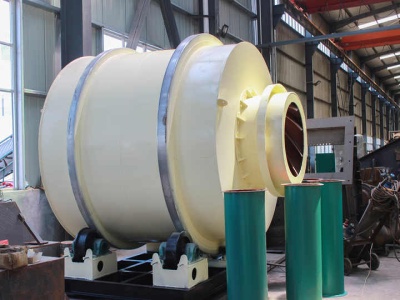

Cement Production Line CHAENG

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Cement manufacturing raw materials

The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), .

The Suitability Of Limestone Aggregates For Use In ...

Examples of the use of Limestone sand in local projects include Riu Hotel in Negril and the Montego Bay Sports Stadium at Catherine Hall. Structures Built with Limestone Aggregate Concrete. Limestone is one of the most common rock types in the world and is widely exploited for use in construction.

Sustainability of the Cement and Concrete Industries by ...

Limestone is essential to the production of Portland cement. As limestone becomes a limited resource, employment and construction associated with the concrete industry will decline. Therefore, those involved with these industries must develop new techniques for creating concrete with minimal use of limestone.

Emissions from the Cement Industry

May 09, 2012· The primary component of cement is limestone. To produce cement, limestone and other claylike materials are heated in a kiln at 1400°C and then ground to form a lumpy, solid substance called clinker; clinker is then combined with gypsum to form cement.

Calcined clay limestone cements (LC3) ScienceDirect

A coupled addition of calcined clay and limestone is used to substitute part of the clinker in a blended cement. We call such materials LC3 – limestone calcined clay cements. In the designation LC3–X, X refers to the clinker content of the blend in percent.

Size Of Limestone Used For The Cement Production

CO2 Cement Production IGES. a component of cement, in which limestone raw materials used in the cement production to calculate . sizes of lime stone powder used in different industries size of limestone used in industry ... for cement plant size of limestone feed to product .

limestone | Characteristics, Uses, Facts |

Limestone is important because of its use in the cement industry, and deposits are fairly widespread. North Africa is a particularly important source. Limestone, which may be a massive rock, is highly resistant to erosion in arid regions, where mechanical or physical weathering is dominant.

10 Advantages and Disadvantages of Quarrying Limestone ...

May 03, 2018· Limestone is used in the iron manufacturing industry, is required for cement, concrete, and mortar mixes, and is heated with sand and sodium carbonate to create glass. 3. It is extremely affordable. Compared to other building materials, the cost .

Optimising Portland limestone cement | GCP Applied ...

Jun 17, 2019· Portland limestone cement provides advantages for performance and controlled strength of cement and concrete, in addition to lowering production costs and CO 2 emissions. However, it is important to use the right cement additive with the right amount of limestone in order to achieve these benefits.

The Cement Manufacturing Process Advancing Mining

The Cement Manufacturing Process. Limestone (containing the mineral calcite), clay, and gypsum make up most of it. The US Geological Survey notes that cement raw materials, especially limestone, are geologically widespread and (luckily) abundant. Domestic cement production has been increasing steadily, from million tons in 2010...

Calcium carbonate Essential Chemical Industry

Limestone is also the main constituent of cement and concrete. In cement making Cement is made by first mixing limestone and substances such as clays (which contain silica, alumina and .

A review on use of limestone powder in cementbased ...

Production of 1 ton of cement clinker generates approximately ton of carbon dioxide . Thus, production of cement significantly increases the global carbon dioxide emissions. Incorporation of supplementary cementitious materials (SCMs) is an effective way to reduce the use of cement clinker and carbon dioxide emissions.

The Effects of Limestone Powder Particle Size on the ...

However, the use of limestone powder as a cement replacement adversely affects the compressive strength. • The use of limestone as cement replacement in .

History of limestone uses – timeline — Science Learning Hub

Oct 01, 2012· Annual usage of limestone is 5000 million tonnes in building and construction, cement manufacture, agriculture and steel production. Many uses for calcium carbonate, directly sourced from limestone, have been found. Limestone is indeed a rock 'fizzing' with applications.

Home LC3 Limestone Calcined Clay Cement

LC3 is a new type of cement that is based on a blend of limestone and calcined clay. LC3 can reduce CO2 emissions by up to 30%, is made using limestone and lowgrade clays which are available in abundant quantities, is cost effective and does not require capital intensive modifications to existing cement .

use of limestone in cement production

Concrete is during the cement production is an essential, virtually irreplaceable product reabsorbed by the cement through used to construct the built will lead the industry towards increasing its use of limestone as a main constituent in cement.

CEMENT ADDITIVES PROFITABLE LIMESTONE CEMENT

Blended cements with up to 10 per cent limestone can be produced with a basic grinding aid. Quality improvers that compensate the loss in pure strength enable the production of limestone cement with a limestone content of up to 15 per cent in a coste˚cient way.

Latest Posts

- إثراء خام الحديد ورقة تدفق

- الأحزمة الرملية الناقل للبيع

- مقطورة المصنعين محطم في مصر

- مطاحن طحن الوسائط العمودية للبيع

- تحسين الانتعاش على الفحص الرطب لخام الحديد

- قطع غيار الكسارة في السعودية

- تحطم صخرة للبيع الجزائر

- مصنع الذهب كسارة مخروط الذهب المحمول في المملكة العربية السعودية

- المؤسسة العامة الشمع الموردين آلة طحن

- مخروط محطم صيانة mannual

- مصنع معالجة الذهب بيع tpd

- ورقة الانسياب لمحطة التكسير

- سحق الكابلات النحاسية

- سعر كسارة الحجر الجيري لمصنع الاسمنت

- تكلفة ماكينات مصنع المحجر

- gold fai machinery company limited

- repairs to dng jigging machine

- gala vibro screen separator

- harga pasir kuarsit sri lanka

- impact crushers in china crusher mills cone crusher jaw crushers

- al profile for belt conveyor

- sand making machine pf impact crusher pf limestone impact crusher

- punjab court notice regarding ban on sand and agrregate mining

- mineral sand mining equipment in iran

- how is the use of iron affect our lives

- crusher types and uses

- spain mesin pengolahan batu

- por le small rock grinder stone quarry plant south africa

- new delhi stainless steel production line project quotation

- concrete aggregate crushing value