technology process of cement

Geopolymer Cement, Geopolymer Technology, Fly Ash .

Geopolymer binder can be used in applications to fully or partially replace OPC with environmental and technical benefits, including an 80 90% reduction in CO2 emissions and improved resistance to fire and aggressive chemicals. Geopolymer cement is made from aluminium and silicon, instead of .

How to Use and Install SoilCement The Spruce

Spread the Cement. You will need about three to four pounds of Portland cement for each square foot of your soil cement surface. Use a bit less for soils with a lot of sand or gravel, and a bit more for soils with more clay or organic matter. Carefully scatter one bag of dry cement over the tilled surface, and then work the cement into the soil with your tiller.

What is curing of concrete? Quora

Jul 23, 2018· Curing of concrete is the process of maintaining moisture in the concrete to ensure an uninterrupted hydration with a definite period to replenish the loss of moisture and to maintain favourable temperature for hydration process, in brief, the process of keeping the concrete moist to enable it to gain full strength is called.

Manufacturing Process White Cement

Clinkerisation is the heart of cement manufacturing process, where the raw material is fed to preheater at controlled rate through electronic weigh feeder. The feed enters the kiln through cyclones and fuel is fired at the kiln outlet end.

Cement Concrete Technology | Cement Chemistry, Process ...

Concrete Cement Handbook and Publications: Processes and Technology. Chemical Publishing Company, established in 1934, prides itself in its commitment to providing scientists, builders, chemists, engineers, reinforced concrete designers, technologists, and other professionals with up to date and cutting edge publications.

PROCESS AUTOMATION OF CEMENT PLANT

1. Introduction The Indian cement industry is the second largest producer of cement in the world, just behind China but ahead of the United States and Japan [1]. In this paper, the overall concept of manufacturing process is taken from ACC CEMENT LTD and various cement manufacturing groups of .

421 Solidification/Stabilization FRTR

Pozzolan/Portland cement process consists primarily of silicates from pozzolanicbased materials like fly ash, kiln dust, pumice, or blast furnace slag and cementbased materials like Portland cement.

Digitalisation in the cement production process | FLSmidth

The cement production industry is realising the potential of connectivitybased technologies, often referred to as Internet of Things (IoT) technologies. We see it as the convergence of information and operations technology, providing valuable data about plant equipment.

Process of manufacture of concrete SlideShare

Nov 08, 2014· Process of manufacture of concrete. It is not used either in RCC or on upper floors. Tamping • It is a method in which the top surface is beaten by wooden cross beam of cross section 10 cm x 10 cm. both compaction and leveling are achieved simultaneously. It is mainly used for roof slabs and road pavements.

Shrinkage in Concrete, Definition, Types, and Factors ...

Just as the hydration of cement is an ever lasting process, the drying shrinkage is also an ever lasting process when concrete is subjected to drying conditions. The drying shrinkage of concrete is analogous to the mechanism of drying of timber specimen.

Concrete Technology Pdf Notes – CT Pdf Notes Eduhub ...

The Concrete Technology Notes Pdf (CT Notes Pdf) book starts with the topics covering Portland cement, Mineral and chemical admixtures, Classification of aggregate, Factors affecting workability, Water / Cement ratio, Compression tests, Factors in the choice of mix proportions, Light weight aggregates, Workability etc.

'Nature's cement' is key ingredient in new road paving ...

Jun 14, 2019· 'Nature's cement' is key ingredient in new road paving technology. ... The county decided to use a new repaving process developed by Lithified Technologies on two sections of .

Solidiatech | Where Sustainability Meets Profitability

Solidia Technologies ® is a cement and concrete technology company offering patented processes that ease production, reduce costs, and improve performance of cement and concrete, while reducing the carbon footprint of concrete up to 70% and water use up to 100% during manufacturing.

Use of process analyzers in Cement cement plants .

process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process. Currently, about 80% of the cement produced in the United States is manufactured using dry process technology. With the development of preheater and precalciner technology, energy efficiency within cement production

Company profile KHD International

Excellence. KHD is a customerfocused engineering, equipment supplier, and service company, providing a fullline of competitive and environmentally friendly technologies to the cement, founded back in 1856, is a global leader in cement plant technology, equipment, and services and hence, the right partner for all your demands.

Portland Cement Manufacturing Industry: National ... US EPA

Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone, clay, sand, and iron ore in a rotary kiln. The kiln is a large furnace that is fueled by coal, oil, gas, coke and/or various waste materials.

The Secrets of Ancient Roman Concrete HISTORY

Jun 21, 2013· History contains many references to ancient concrete, including in the writings of the famous Roman scholar Pliny the Elder, who lived in the 1st .

New technique could make cement manufacturing carbonneutral

Sep 28, 2015· During cement manufacturing, there are two steps responsible for carbon emissions. One is calcination, when limestone, the raw material most used to produce cement, is heated to about 750 degrees Celsius. That process separates limestone into a corrosive, unstable solid—calcium oxide, or lime—and carbon dioxide gas.

principles of concrete mix ACC Help

Cement Cement is a fine powder, which when mixed with water and allowed to set and harden can join different components or members together to give a mechanically strong structure. Although the percentage of cement in concrete is around 15%, the role of cement is very important in the strength and durability of concrete.

Process Compatible SO2 Control In Cement Kilns

There are three important objectives that any process compatible emissions control technology must meet to function in the cement manufacturing process. First the control technology must succeed at controlling the pollutant of intent, preferably at control levels that are in the same range as traditional endofpipe technologies.

Chemical Technology cement mill process flow chart ...

Chemical Technology cement mill process flow chart 50594x514 # – Cement Mill Process Flow Chart, with 44 Similar files. Chemical Technology cement mill process flow chart 50594x514 # – Cement Mill Process Flow Chart, with 44 Similar files. Free Printable Documents Templates

Latest Posts

- محرك دويتس لمحطات الكسارة

- كسارة الصخور العمانية المستخدمة

- دليل التكسير والغربلة

- آلة كسارة في اليمن

- عملية تكسير الطوب الرملي

- الصين خط إنتاج رمل السيليكا مصنعين

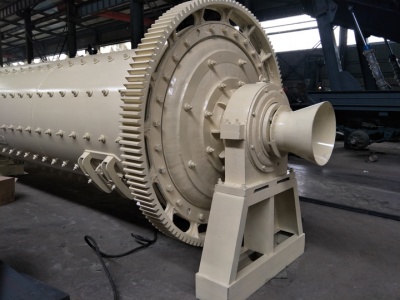

- تحسين مطحنة الكرة في مصنع الاسمنت

- الآلات الكاولين للبيع في تركيا

- كسارة متنقلة مستعملة للبيع نيوزيلندا

- معمل تكسير وتجهيز حديث للخرسانة

- النحاس العمودي عالية طحن مطحنة

- السودان المحمولة كسارة أثر كسارة

- كسارات الصخور الحجرية

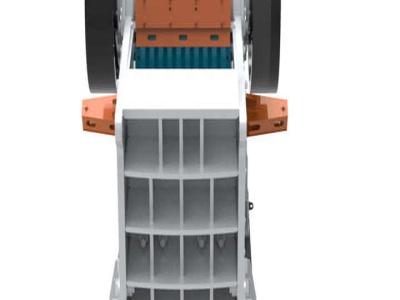

- كسارة الفك كسارة مخروط vsi في واحد

- سحق كسارات المنغنيز

- convex diamond grinding cup wheels

- stone crusher safer at chikkamagalore

- mobile coal cone crusher for sale nigeria

- c crusher vedios

- be1 11g generator protection system basler

- gold mining company in china gmail

- quarry crusher for sale in germany

- quarry di indonesia

- fire dried quartz sand prices

- belt conveyor mills

- available learnerships in electrical engineering

- used concrete crusher plants for rent

- quarry stone crusher plant flow diagram

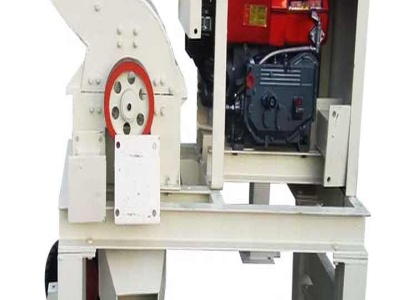

- mb jaw crusher buckets

- mass lance cement milling