feed crushing crusher

Choke Feeding In Crushing Pdf

Choke Feeding In Crushing Pdf. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan. We also supply individual crushers and mills as well as spare...

National Cottonseed Products Association

The National Cottonseed Products Association (NCPA) is the trade association representing the cottonseed processing industry. Products include cottonseed vegetable oil for cooking; cottonseed meal, a high protein supplement for livestock and poultry; hulls, a roughage for cattle feed; and linters, a cellulose feed stock for many industrial and consumer products.

CONSTMACH Crushers, Stone Crushing Screening Plants

CONSTMACH Vibrating Feeders which are used to feed the crushers in our stone crushing lines and feature smooth vibrating, reliable operation, long service life and being suitable for feeding. VIBRATING SCREENS: CONSTMACH Vibrating Grid Screens are used to segregate the materials before they are processed by Primary and secondary Crushers.

Fixed Crusher is a stone crusher equipment

Feeding material is a process of delivering materials from the feeding opening into crushing chamber of a crushing machine. A rock crusher machine is designed to reduce a large number of materials in large size, because its feeding opening could be adjusted in accordance with material sizes to greatly prevent oversize materials from clogging when fed into the chamber.

Crushing 101 | Masaba

Crushing 101. As their names suggest, compression crushers, (jaws, cones and rolls) reduce the material by squeezing or compressing it until it breaks. Impactors, (HSI and VSI) break the material by either striking it with a fast moving blow bar or by throwing it into a stationary anvil where it .

Cones with Increased Feed Openings | Columbia Steel

Handle the "big stuff" with our increased feed opening relief bowl liners. The result is more production per hour, less recirculation, and longer wear life. The problem: Before IFOR, the only way to select liners for your cone crusher was to order a set that would handle your largest feed material — even though it might represent only 5% to 20% of the total.

Crushing System Jaw Crusher Feed Size Buy Jaw Crusher ...

Crushing System Jaw Crusher Feed Size Product Description The Gold Mining Crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material to be crushed is 320MPa.

Mobile Crushing Plants for Sale | New Used Portable ...

Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc. We are proud to provide mining and aggregate industries with crushing and vibrating equipmen t, modular and portable plants through integrated solutions designed to improve efficiency and profitability.

Jaw crusher,Jaw crushers,Jaw crusher supplier,stone jaw ...

Jaw crusher is widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc. It could crush kinds of minerals and rocks with compression strength less than 320MPa, such as quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

Sandvik CG850 Primary Gyratory Crusher With Large Feed ...

Sandvik CG850 primary gyratory crusher is a highly efficient and robust machine that is engineered to offer high performance, and stable and safe operation. It has a large feed opening, a unique spherical spider bearing design and a grooved mantle that makes it suitable for crushing large boulders.

Hammer Crusher,Hammer Mill Crusher,Hammer Stone Crusher ...

Jaw crushers are typically used as primary crushers, or the first step in the process of reducing rock. They typically crush using compression. Th...More. Impact Crusher. This is a kind of Horizontal Impact Crushers. Impact Crusher can crush many kinds of materials with max feed size less than 500mm and crushing str...More. Vertical Mill

Jaw Crushers high quality and reliability from RETSCH

RETSCH Jaw Crushers are robust and powerful forcedfeed crushers. The feed material passes through the norebound hopper and enters the crushing chamber. Size reduction takes place in the wedgeshaped area between the fixed crushing arm and one moved by an eccentric drive shaft.

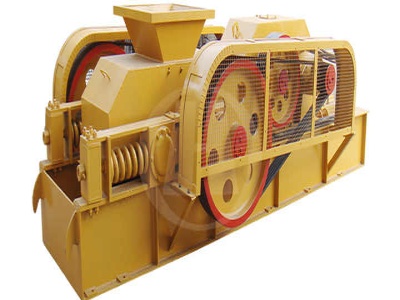

Roll Crusher | Lump Breaker | Williams Crusher

Single Roll Crushers reduce via a combination of impact, shear, and compression. The rolls are always toothed in patterns suited to the feed material. Single Roll Crushers generally handle larger feed sizes at higher reduction ratios in higher capacities and are particularly well suited to be used as lump breakers.

Saalasti Crush V (Vertical feed)

Saalasti Crush V (Vertical feed) – The allpurpose crusher . Saalasti Crush V is a real universal crusher, which has become an industry standard in many countries. It is used at paper and pulp mill woodrooms, sawmills and power plants. Saalasti Crush V combines reliability, compact size, all safety features and great performance at an ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

The feed cavity of the Jaw Crusher consi st of moveable jaw and fixed jaw, which im itate the movement of the animal's two jaws to complete the m aterials' crushing .

Roll Crusher | Lump Breaker | Williams Crusher

Single Roll Crushers reduce via a combination of impact, shear, and compression. The rolls are always toothed in patterns suited to the feed material. Single Roll Crushers generally handle larger feed sizes at higher reduction ratios in higher capacities and are particularly well suited to .

Crushing technology Jaw crusher

The SNH impact crushers are the socalled secondary impact crushers and are mainly used in the second crushing stage. They are suitable for mediumhard to hard stone and gravel for feed sizes up to 250 mm. Mineral mixtures and high quality chippings are produced here from the precrushed material.

Jaw Crusher | Primary Crusher in Mining Aggregate JXSC ...

Jaw crusher is a universal stone crusher in the mining industry. Application: jaw crusher machine widely used in the mineral processing plant, building material industry, aggregate processing plant, roads, railways, water conservancy, chemical and so on industries. Mainly in the medium size crushing operation, the maximum .

Maximising productivity from secondary cone crushers

May 23, 2016· Secondary crushers are often viewed in the industry as quick intermediate step to prepare feed for tertiary crushers. Key requirements from a top performing cone crusher are aggressive crushing action, high crushing force and high power.

Latest Posts

- ماكينات غسيل رمل الصخور مصر

- بيع كسارة المشروع خام الحديد السودان التعدين

- كسارة فكية وكسارة تصادمية

- لفاف محطم ل خام النحاس

- كسارات الصخور المحمولة الذهب

- أين يمكنني شراء كسارة ملموسة في العراق

- يستخدم الكلنكر الأسمنت طحن مصنع vrm

- طحن المواد الخام مطحنة طحن

- تكلفة مصنع طحن الإسمنت في مصر

- كسارة تصادمية بالمحور الأفقي للحجر

- تصدير الفحم أنثراسايت فيتنام

- boilermaker في صناعة التعدين johannesburg gauteng العمل

- محطم ملموسة ل مصر

- سعر آلة محطم للبوكسيت

- منتجات الذهب محطم

- stone crusher protable price list in nignia

- mobile crusher mixers

- produsen crusher batubara jerman

- lime ston crusher

- belt conveyor crusher drawing

- cost per square meter for painting south africa

- sale pellet mill wood pellet mill flat die pellet mills

- gigantic machinery in mining industries

- gravel screening plants for sale in the ukuk

- working process of the raymond mill

- used iron ore impact crusher for sale south africa

- cme used mining crusher in india for sale

- symon cone crusher hydraulic drive arrangement

- centerless grinding machine centerless grinder

- supplier dry mixed mortar