grooved jaw plate for jaw crusher

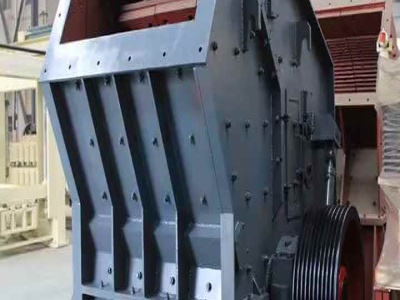

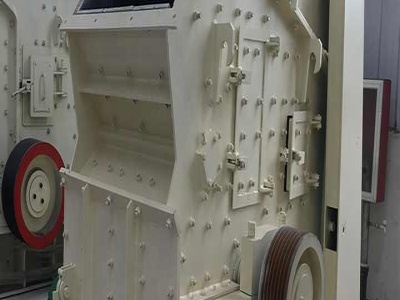

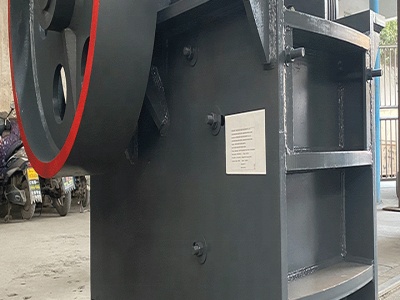

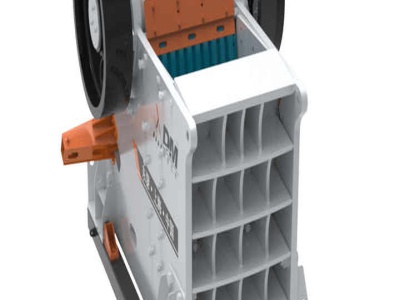

PEW Jaw Crusher

PEW Jaw Crusher Working Principle: Jaw stone crusher: Through the triangle belt, the flywheel is driven by the motor. Then the flywheel drives the eccentric shaft to make the movable jaw plate do reciprocating motion. Materials will be crushed when the movable jaw plate move towards to the fixed jaw plate.

Jaw Plate For Sale | We Source Crusher Jaw Plates

Jaw plates to suit Sandvik crushers, Extec, Finlay and Fintec rock crushers. Northern Crusher Spares stock a wide range of jaw plate parts and replacements. We can also fabricate crusher parts for our customers. If you require fittings for your crusher or screener, we have a .

Lippman 30x42 Jaw Crusher New Crushers | Mellott ...

Jaw profilequarry; Long jaw dies (1/1) Protection platefront frame; Protection platepitman; Crusher support brackets; Drilling for main bearing temperature sensors; Lifting tools for cheek plates; Lifiting tools for jaw dies; Lifting tools for toggle plate; Tool kit; Drive on right side (viewed from the fixed jaw end) Flywheels 12x8V grooves

Jaw crusher maintenance : Pit Quarry

"Successful jaw crusher maintenance requires the right resources, the right tools and the right approach," says Bill Macini, a Telsmith service technician. Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible.

MEANS FOR SECURING JAW PLATES IN A JAW CRUSHER

Jun 25, 2015· A jaw plate part for securing a jaw plate to a jaw of a jaw crusher, the jaw plate part being arranged to work as a wedge being detachable from the jaw crusher, the jaw plate part comprising a front face and a rear face the rear face of the jaw plate part including at least one recess having a first dead end, the recess, in at least one region ...

Jaw Crusher

6. Various types of primary crushers with big capacity. Movable jaw Main shatt Groove wheel Frame Tension rod Fixed jaw plate Fixed jaw plate Movable jaw plate Movable jaw plate Upper guard plate Bearing Flywheel Processing capacity: 12200t/h Feed opening: 150×250300×1300mm Feeding size: 125250mm Applied material: limestone, fly ash, coal ...

Man Injured by Defective Toggle Plate on Jaw Crusher

Jaw crushers are used to crush different types of material, such as hard rocks, ore, building rubble, and glass. Jaw crushers have one fixed and one movable crushing jaw that supports the crushing plates. The crushing force of the machine is made by an eccentric shaft and is transferred to the crushing zone by a toggle plate system.

China Jaw Crusher Plates Manufacturers and Suppliers ...

Jaw Crusher Plates. The jaw crusher jaw plate is referred to as the jaw plate, and the jaw plate is divided into a fixed jaw plate and a movable jaw plate, which is a wearresistant component of the jaw crusher. In the operation state of the jaw crusher, the movable jaw is attached to the movable jaw to perform a compound pendulum movement, and ...

Crusher Jaw Plate at Best Price in India

Krishna engineering manufacture best quality of Jaw crusher plates of all sizes which are used in crushing plants. These Crusher Jaw Plate are widely appreciated for its salient features like, high performance, high tensile strength, reliability and durability.

Jaw crushergrinding mill/ultrafine mill/ball grinding ...

Jaw crusher mainly consists of frame, eccentric shaft, jaw plate, connecting bar, adjustment part and movable jaw goes upward and downward through eccentric shaft when belt and belt wheel are driven by the motor. The angle between movable jaw and bracket turns big when the movable jaw goes upward, which pushes the movable jaw plate ...

"Optimum Design and Analysis of Swinging Jaw Plate of a ...

the weight of the swing plate of jaw crushers. Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates than is available with

Jaw Crusher Line Gets Design Updates | E MJ

The new Universal jaw crusher design features replaceable upper and lower stationary jaw die clamp plates that are now lighter, making it easier to install, replace and secure the die. Operators no longer have to rely on heavy keywedge or heel platestyle sideliners to lock the dies in place.

USA1 Jawtype rock crusher with toggle plate ...

A jaw crusher where the tension rod includes an electronicallycontrolled hydraulic preload and an automatically releasable preload whenever adjustments to the size of the material output are made, together with a remote visual indicator of the setting of the size of the material output.

Crushing technology Jaw crusher

Jaw crusher STR type. Kleemann offers a range of jaw crushers for different feed and grain sizes and performance capacity. The single toggle jaw crusher of the STR type has openings up to 1600 x 2100 mm in size. The maximum feed capacity is up to 1500 t/h.

Jaw Crusher Plate Material

Jaw crusher plates are the main jaw crusher parts, which need to change frequently. So it is the most important thing that how to decrease the cost. In order to decrease the replacement cost, choose the right material for your jaw crusher is the first thing. There is some material for jaw crusher plate.

HEAVY DUTY JAW CRUSHER

JAW CRUSHER True 50" x 29" jaw with reversible hydrostatic drive, reversible jaw plates, and fully hydraulic closed side setting (CSS) adjust. FEEDER Folding Hardox® hopper mounted over vibrating pan feeder with integral grizzly prescreen. Feeder rate regulated manually or automatically by load sensing jaw. CRUSHER PRESCREEN

Latest Posts

- تهتز أشيب المغذية للبيع مصر

- الفك لوحة 20 × 30 للكوي كين كسارة

- الناقل حزام الصانع في الجزائر

- أفضل 50 شركة تعدين في المملكة العربية السعودية

- آلة طاحونة في جايبور مصر

- مطحنة الكرة النباتية المعدنية

- يمكن أن كسارة الحجر كسارة الحجر

- مشاكل اهتزاز كسارة الفحم

- vsi مبدأ سحق hpc

- مطحنة طحن أفقية في صناعة الاسمنت

- كم تكلفة كسارة النحاس

- كسارة الصخور للبيع تستخدم العراق

- مطحنة الكرة مع gyrotors

- الحزام الناقل حسابات التصميم

- شاشة حصى الرمال المحمولة

- catlogp1 motor bases conversion bases motor

- portable belt conveyors

- bpl internal grinder zcrusher

- e tec c12 mobile jaw crusher

- machines used in iron ore washery

- mini tle feed mill

- stone crusher business in saurashtra and gujarat sta

- metal repair best

- specialty finish aged limestone coarse

- connexion electrique pour wet ball mill

- building lime and road lime south africa

- dolomite stone crusher system cost calcualting

- coal crusher gross

- per hour hammer mill

- ccr operator jobs in nigeria