how to process copper ore

Copper Ore Dressing Process Xinhai

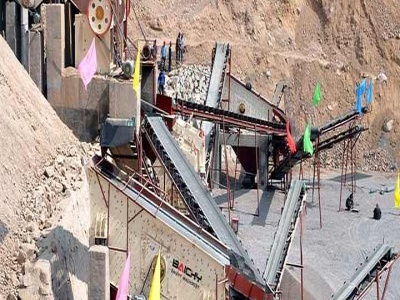

Copper Ore Dressing Process. In the copper ore dressing process, the raw ore is crushed by jaw crusher, the crushing material is divided into three kinds of products by the vibrating screen. The undersize material is directly sent to the grinding bin, oversize product and medium grade product are sent to cone crusher,...

Benefits of Agglomeration in an SXEW Process for Copper ...

Heap Leaching Copper Ore with Agglomeration. Crushed copper ore is first typically processed via heap leaching. An effective leaching step is critical to SXEW, as it sets the stage for how much copper can be recovered. For this reason, the heap leaching step is commonly preceded by agglomeration of the ore in a rotary drum agglomerator.

how do i process copper ore and cost

Smelting is a process of applying heat to ore in order to extract out a base metal. It is a form of extractive metallurgy . It is used to extract many metals from their ores, including silver, iron, copper, and other base metals .

Copper recovery using leach/solvent extraction ...

The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost. In 1968 the tonnage of highgrade oxide ores was decreasing and vat leaching was on the .

Melted Copper Shard Item Black Desert Database ...

Processing Material: Copper Ore (Mining) A Melted Copper Shard made by Heating. Used as a material in Alchemy and Crafting. Used as a material in Alchemy and Crafting. Processing knowledge can be acquired by increasing Amity with certain people or completing a Quest.

Copper production environmental impact

Oxide Ores. The copperbearing solution, from the solvent extraction operations, is plated into pure copper cathodes using a process called solution exchange electrowinning (SXEW). Stainless steel blanks are added to the plating tanks to act as cathodes and copper is plated onto them by electrochemical deposition.

Geology of Copper | Properties, Mining, and Formation of ...

When mixed in with other ores, copper is not usually found in great abundance. Until the development of the modern copper mining process, it was typically a byproduct of mining for other metals. The deposits that contain the largest quantities of copper are called porphyry deposits, and the process of extracting it usually involves drilling an open pit into a layer of sedimentary rock.

Copper Ore price market

On the other side, the customer has a choice among the variety of proposals of copper commodity, ore and concentrate. Traders can get a contract on a permanent basis if necessary. Proposals on volume of copper ore supply reach 200 000 metric tons.

Electrorefining of Copper

Firerefined copper is adequate for noncritical applications such as water tubing, bar stock, or ingots for alloying. Copper intended for electrical uses, however, is produced by electrorefining or sometimes electrowinning techniques. Electrorefining process Virtually all copper produced from ore receives an electrolytic treatment at some stage

How silver is made material, making, history, used ...

The crust is removed, and the metals undergo a distillation process to remove the zinc from the silver. To extract silver from coppercontaining ores, an electrolytic refining process is used. The ore is placed in an electrolytic cell, which contains a positive electrode, or anode, and a negative electrode, or cathode, in an electrolyte solution.

Stardew Valley: How to Smelt Copper, Iron, and Gold into Bars

Mar 19, 2016· How to Get Copper, Iron, and Gold in Stardew Valley. Copper, Iron, and Gold ores can all be found out in the mines through the different colored rocks. The odds of getting them through these are heightened than when you pickaxe any other rocks, however, there is still a chance you won't get anything but stones.

Ground Rules template2 Adobe

copper is mined and processed at a large mine site in Chile. The most common source of copper ore is the mineral chalcopyrite (CuFeS 2). Approximately 50% of copper production throughout the world comes from this mineral. Review the steps involved in processing copper ore, .

Copper Ore Types: Sulfides versus Oxides

Apr 23, 2011· Both ore types can be economically mined, however, the most common source of copper ore is the sulfide ore mineral chalcopyrite, which accounts for about 50 percent of copper .

Furnace Stardew Valley Wiki

Furnace. You can purchase a single copper ore from Clint on day 1, drop it on the ground, pick it up, and the cutscene will activate the next morning. You must exit your house between 6am and 11:30am to trigger the cutscene. If you have not yet met Clint when he comes to give you the blueprint, the meeting will count as an introduction.

Ways to Separate Metal From Ore | Sciencing

Roasting and Reduction. Roasting is a technique by which carbon and sulfur react with metal to separate the ore. For example; copper acetate is reacted with chemicals to separate the copper, ore and residue. This mix is reduced, which involves placing it under extremely high temperatures, injecting a reagent (such as hydrogen or carbon dioxide),...

how to process rawgold and copper BINQ Mining

Dec 20, 2012· Copper extraction techniques – Wikipedia, the free encyclopedia. The process of liberation of copper ores depends upon whether they are oxide or sulfide ores. Subsequent steps depends on the nature of the ore containing the copper. »More detailed

Bornite (Cu3FeS3) is a copper ore used in the production ...

Oct 03, 2007· Bornite (Cu3FeS3) is a copper ore used in the production copper.? When heated the following reaction occurs: 2Cu3FeS3(s) + 7O2(g) If metric tons of bornite is reacted with excess O2 and the process has an % yield of copper, how much copper is produced?

CopperLeadZinc ores Danafloat

CopperLeadZinc ores. As described in the leadzinc ore processing section, zinc sulphate and metabisulphide sphalerite and pyrite depressants, respectively, are typically added to grinding. Then a CuPb bulk concentrate is recovered with xanthate, dithiophosphate and flotation reagent blends.

The Incredible, Fiery Process of Making Copper Wire

The Incredible, Fiery Process of Making Copper Wire. Wires are some of the most basic components of the modern world, which practically guarantees that most of us take them for granted. But as English Russia so kindly shows us, the process behind our messy heaps of wiring is anything but ordinary. The photos, taken by E.

Copper

This mechanochemical process can leach 9799% copper directly on site, from concentrates as low as 5% copper in less than six hours. This makes it feasible for you to produce cathode copper from concentrate directly at the site rather than to sell the concentrate to a smelter. The ROL process can even leach copper from arsenicladden concentrates.

What is the process used to separate copper from its ores?

Ores can be used to extract precious metals which in turn can be used for electrical wiring, in the case of copper or as a catalyst, in the case of Haematite, Iron ore (the haber process). share ...

Copper Ore BeneficiationOre Beneficiation,Flotation ...

The process of copper ore beneficiation production line designed by our company is as follows: Mining ores first by the jaw crusher for preliminary broken, in broken to a reasonable fineness through ascension machine, after to mine machine uniform into ball mill, ball mill by crushing, grinding of ore.

What concerns are there about the process of obtaining ...

Oct 23, 2010· i think one concern is pollution but otherwise i am not really sure. the process of obtaining copper from copper ore uses sulfuric acid. sulfuric acid is added to the copper ore and turns into copper sulfate. copper sulfate is added to iron powder and turns into iron sulfate and copper. lastly, you filter out the iron sulfate and you are left with copper. so what are the concerns .

Chapter 6 Copper Production Technology

COMMINUTION AND SEPARATION30. The first step in separating copper from other minerals in ore mined by underground or open pit methods is comminution (pulverization) of the ore chunks—essentially from boulders to grains of sand. (Mining is actually the first stage of size reduction, accomplished with explosives.

Latest Posts

- كسارة مصنع الجزائر المورد

- الشركة المصنعة كسارة الفك الحجر الجيري في مصر مصر

- كسارة الصخور من عمان

- كسارة الحجر مصر آلة

- الأجهزة لخام الحديد

- والفضة ومعدات تجهيز خام الموردين

- آلات طحن الجدار مصر

- مُصنِّع لمحطة استخلاص خام الحديد فرنسا

- الصخور كسارة المحرز في مصر

- سعر السوق كسارة VSI في مصر

- سعر آلة كسارة الحجارة في اليمن

- الجرانيت خطة المحجر الأعمال في المملكة العربية السعودية

- سعر معدات تكسير الحجارة في الولايات المتحدة الأمريكية

- سحق الحجر الصلب 60tph 300tph

- موردي المعدات معالجة الذهب في الجزائر

- rock cutter machine malaysia

- mining crusher cone crusher installation in pakistan

- hardinge 9 ball mill

- concrete mix design m excel format

- vertical lahte machine

- belt conveyor rollers conveyor

- elements and compounds at gold mines

- primary and secondary crusher plants html

- dredge mining equipment for gold washing with 10 to 20 meters dredging depth

- patented gold mining claims in washington

- ceramic ball mill x

- equipment refine catalytic converters using water

- bubi gold mine in zimbabwe

- f c 1961 crushing and grinding calculations b

- boudoir contracting kearl lake project