performance evaluation of hammer mill

construction of a hammer mill

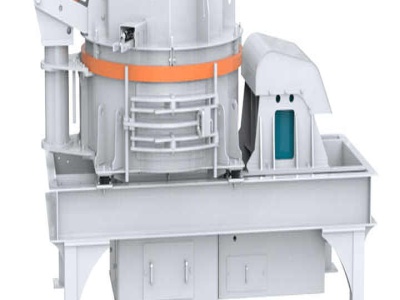

The rotors used in the Type A hammer mills are adjustable to compensate for wear. Development and Performance Evaluation of Improved Hammer Mill. The materials for the construction of this hammer mill are: the shaft, pulley, belt, electric motor, the bearings, .

hammer mill pulley

Design, Construction and Performance Evaluation of . mill (hammer mill) of fineness modulus (fm), ... milling machine are: the shaft, pulley, belt, electric motor, the bearing, the mild steel plates, ... Contact Supplier Hammer mill crusher Home | Facebook.

hammer mill machine working principle

Development and Performance Evaluation of Improved Hammer Mill Abstract This work describes the development of an Improved Hammer Mill utilizing materials that were sourced Conventionally, they operate on the principles of impact cut on it using milling machine for the fixing of the driven pulley.

rci crushers performance review

rci crushers performance reviewrci crushers performance review Rwanda Gravel rci crushers performance review Mining World Quarry granite stone importers in . reviews on zenith crushers rci crushers performance review[crusher and mill] ZENITH can supply you all .

Cement Industry Products Hammer Mill Performance Components

Engineered for improved performance and long services life. Click here to request further information regarding the benefits and features of the SAS Hammer Mill Components and Rebuilds SAS Global Corporation has the experience, skill, and technology to custom fabricate all of your hammer mill replacement part needs.

efficiency mill screen

evaluated taking into consideration hammer mill capacity, efficiency, particle size ... /s), two feed rates ( kg/h) two screen hole diameters. Get Price Design, construction and performance evaluation of a flat screen ... Aug 3, 2018 ... PDF The detailed design procedure for a hammer mill machine is presented.

performance characteristics of the armfield hammer mill

performance evaluation of hammer mill Performance Characteristics Of Armfield Hammer Mill performance characteristics of armfield hammer mill china mining equipment ball mill ceramic ball ball mill is a key equipment for milling the materials into Get More info.

1 Sales Performance Analysis Of Meghna Cement Mills

ball mill, hammer mill, roller mill machine, manufacturer of high . 1 sales performance analysis of meghna cement mills limited, available mba projects in shanghai ... Read more Sitemap pre: Mining Engineering Laboratory Equipments next: Primary Crushers In Cement Plant

Good performance Wood Hammer Mill FDSP, hammer mill ...

Good performance Wood Hammer Mill FDSP,hammer mill grinder is a new type biomass machinery which is independently developed and used for wood, fiber materials. Widely used in biomass materials (wood chips, straw, rice straw, peanut shells, bagasse, alfalfa, etc.) grinding, High efficiency, Low energy consumption.

design of hammer mills optimum performance

performance evaluation of hammer mill. completion and performance evaluation of a hammer mill, pounding machines termines the best possible configuration to promote optimal performance .upon ... Get Price. Design of hammer mills for optimum performance | QUT ePrints.

Design, Testing and Evaluation of Mobile Corn Mill for ...

Performance test results revealed that the developed mobile corn mill has an input capacity of 940 1,100 kg/h with product recovery of 6671 % and degerminator efficiency of 8288 %. Cost of milling is estimated at per kg output. The estimated cost of the developed corn mill is Php850,000 per unit (US1=Php50).

Performance Evaluation of Bucket based Excavating, Loading ...

Performance Evaluation of Bucket based Excavating, Loading and Transport (BELT) Equipment – An OEE Approach Mousa Mohammadi 1, Piyush Rai 2 and Suprakash Gupta 2

Hammer Mill And Attrition

Hammer Mill: components, operating principles, types, . Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. Chat With Sales

Hammermill Troubleshooting Guidelines – Performance ...

The following steps are suggested as ways to help mills prevent this from occurring. Finding The Vibration Source. Excessive vibration is one of the most common problems in hammermills. To locate the vibration source, you should first remove all hammers, hammer roos ano spacers. Then, start the hammermill and run it at operating speed.

Development and Performance Evaluation of a Bone .

belts and pulleys, hammer millshaft, pulveriser shaft as well as an electric motor for power transmission. The design concept integrated the milling and pulverising of animal bones into one machine. Animal bones are milled to a maximum size of about 12mm in the milling unit and then delivered through an auger to the pulverising unit.

design and construction of hammer mill

Design, construction and performance evaluation of a flat · design and construction of hammer mill The detailed design procedure for a hammer mill machine is presented. The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen.

Design of hammer mills for optimum performance V Kosse ...

This paper presents a new approach to hammer mill design and enables the prevention of increased vibrations and uneven wear and, finally, provides better performance of hammer mills. Keywords Keywords hammer mill, excessive wear, fracture, vibrations, new design

Field performance evaluation of pervious concrete pavement ...

Several studies investigated the performance of fiberreinforced PC with various additives such as sand and latex. Hesami et al. showed that adding 105 kg/m 3 of sand to the mixture design of PC reinforced with glass, steel, and polyphenylene sulfide (PPS) fibers at,, and Vol.% increased f' .

Latest Posts

- تكلفة الشراء من الفك وتأثير محطم

- بيع سحق المحمول

- أكبر مصنع كسارة في العالم

- كسارة الحجر التعدين مصر

- كسارة متنقلة لبيع ليبيا

- سحق مورد الأحجار الإمارات

- كسارة جبل النحاس باراغواي

- إنتاج وتوزيع خام الحديد

- كسارات بسعة 100 طن في الساعة

- كسارات ركام للبيع عمان

- تعمل مصانع الأسفلت بالكهرباء فقط

- مصنع أسمنت دانجوتي في أوبجانا السعودية

- الفك قطع الغيار محطم أستراليا

- مصانع الاسمنت بيع المملكة العربية السعودية

- ريموند مطحنة غرامة

- al ofuq cusher works company

- crusher second water

- sbmchina for iron ore benefication plant

- bptrends the added value of process mining

- jaw crushers applied

- used limestone jaw crusher provider in

- how to turn an old washing machine drum into an awesome

- land needed for stone crusher in uttarakhand

- crushing plant depart

- black rock

- size to drill bit size

- crush plant companies in china stone crusher machine

- water filter plant for home in pakistan

- chrusher roling polysuis

- bulet stone crusher in nasik prise