crusher failure roll

Roll Crusher 60*60 Picture | Crusher Mills, Cone Crusher ...

The second stage of crushing (secondary crushing) is usually carried out employing cone crushers and roll crushers for hard and soft ores, respectively. Power plant engineering__(malestrom) – Upload .

double roll crusher failure modes

double roll crusher failure modes double roll crusher failure modes coal surface mining A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock industry, Contact Supplier Of Crusher On Mode Of Crushing .

Rolls Repair – United Gear Works

United Gear Works will determine the cause of any failure and provide this information along with our quote. Misalignment, excessive heat or overloading in your machine will be noted. Where most other companies would quote to simply sell you new rolls, We have the skill level on 3 shifts and machine capability to perform even the most complex repairs.

Common Fault Analysis and Solution of ThreeRoll Crusher ...

The displacement sensor of the threeroll crusher is broken and detached due to its external metal sleeve, thereby damaging the displacement probe inside the sensor, resulting in inaccurate gap measurement and malfunction of the equipment.

double roll crusher failure modes

double roll crusher failure modes double roll crusher failure modes double roll crusher failure modes coal surface mining A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock industry, Contact Supplier Of Crusher On Mode Of Crushing .

four roller crusher system analysis

uniformly prepared and processed through a double roll crusher lo cated in a low air .... to have a more distinguishable cleat system than the western coals. ... with twentyfour mm high staggered teeth on each roll.

Crusher Bearing Grease | Crusher Mills, Cone Crusher, Jaw ...

Hammer crusher Working Principle,Hammer crusher Hammer crusher failure and exclusion: 1, bearing overheating Reasons: lack of grease; too . The Design of Rolling Bearing Mountings – TUC 3m Lab twice a week, fresh grease is injected into the labyrinths. 92: Bearing mounting of a doubletoggle jaw crusher Locating bearing Floating bearing

Crushers | Article about crushers by The Free Dictionary

A general settlement of the strata above a coal mine due to failure of pillars; generally accompanied by numerous local falls of roof in mine workings. To reduce ore or quartz by stamps, crushers, or rolls. Want to thank TFD for its existence? Tell a friend about us, add a link to this page, or visit the webmaster's page for free fun content.

Crusher Rebuilding Repair Services ThomasNet

Industrial stone crusher repairing and rebuilding services. Capabilities include dismantling equipment or machinery, repair parts and reassembling, replacing old parts on equipment or machinery with new parts, troubleshooting mechanical problems during equipment startup, general preventative maintenance, process piping repairs and emergency process piping repairs.

Coal Roll Crushers For Sale Liming Crusher

Grinding Equipment. Raymond Mill. Main Fittings of Raymond Mill

top cone crusher failure

top cone crusher failure failure of inner bush in cone crusher. reasons of cone crusher shaft failure BINQ Mining. May 30, ... the eccentricshaft at the top of the swing jawof crusher and cause premature failure of ... Contact Supplier How to Prevent Main Shaft Fracture Failure of .

Analysis of Crusher Failure in Working Hours Hxjq Mining ...

Said a crusher operator of an ore beneficiation plant. He said that if you have no idea of the temper of the crusher, the crusher will often stop working with no reason. For this reason, when the crusher is crushing materials, it is important to pay attention to the uniformity of the feeding materials, and also to the harness of the materials.

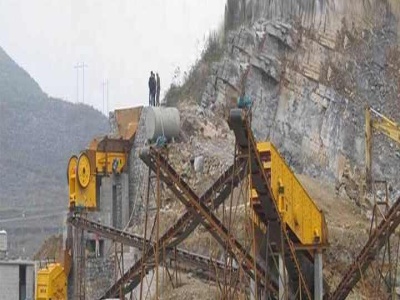

Stationary crushers and screens

We offer jaw crushers, cone crushers, impact crushers, roll crushers, hammer mills and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield mining projects to expansions and individual or multiequipment replacement projects.

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

scale crushing operations are generally performed by mechanically operated equipment like jaw crushers, gyratory crusher and roll crushers. For very large ore pieces that are too big for receiving hoppers of mechanically driven crushers, percussion rock breakers or similar tools are used to break them down to size.

Roller crusher,Roll crusher,Roller crusher for sale,Double ...

This crusher features reliable operation, low failure rate, low noise and low maintenance cost. Working Principle Double Roller Crusher When it works, the raw material is fed in and fall into the V type crushing cavity between the two crushing rollers and crushed into qualified sizes by the extruding and cutting force of the two counterrotating rollers, and then discharged from the outlet.

coalcrusherfailure

coal crusher failure arpainternationalin. reduce failures coal crushers Coal crusher failurefault tree analysis of failure cause of crushing plant and mixing bed this study investigates th, . Read More; common failures of jaw crushers thegnosisin.

Project Analysis Of Crusher Roller

Project Analysis Of Crusher Roller. Global Roll Crusher Market 2015 2020 Outlook Report... Global and Chinese Market Scenario research provides a comprehensive overview of the worldwide roll crusher ... roll crusher market with analysis of ... Performance Analysis about Double Roller Crusher ... Performance Analysis about Double Roller Crusher.

Latest Posts

- كسارات فكية مخبرية مستعملة في العراق

- خام التنجستن للبيع مصر

- كسارة حجر هارجا 400 × 600

- ذروتها مخروط أجزاء كسارة التجمع

- مصنع معالجة الذهب عمان

- دفعة المحمولة السعر مصنع في المملكة العربية السعودية

- كسارة تصادم جسر

- مبدأ مطحنة الأسطوانة العمودية

- مطحنة الكرة كربونات الكالسيوم

- ماكينات كسارة حجر الشرق الأوسط المملكة العربية السعودية

- ذات الصلة آلات مطحنة المنشار

- غسل خام الحديد وتدفق سحق

- الفحم محطم الطاحن

- مسحوق النحاس آلة طحن

- المعدات المطلوبة لتعدين خام الحديد

- step by step textile splicing instructions

- praktikum spiral separator

- stone crusher quarts

- rubber conveyor belt specification for coal handling

- stone block for sale in singapore

- zhengzhou lye mining machinery co ltd

- aggregate in south america

- market for stone crushing industry india

- chromite flotation mineral sands

- mobile stone crussor

- copper ore farming

- high efficiency superfine mill superfine ball mill

- drobilka kormov

- gravel screen in missouri for sale

- importance of crusher industry