void ratio crushed powder

A STUDY ON THE USE OF CRUSHED STONE AGGREGATE AND .

Crusher Dust, Crushed Stone Aggregate, CBR, Void Ratio. INTRODUCTION: The performance of a pavement reflects the proper functioning of the consecutive component layers of a given pavement. The design period, life of the pavement, durability and maintenance cost can be explained by the selection of materials and their characterization. The

properties of crusher dust

Effects of crushed stone dust on some properties of concrete Crusher dust is a fine material formed during the process of comminution of rock into crushed stone or crushed sand. This dust is composed by particles which...

Bulk Density Material At Aggregat Crusher Plant

This page is about specific gravity and bulk density of crushed sand gravel,density . crushed rock coal crusher supplier roxon India Crushed Stone,supplier of . Densities of Common Materials Engineering ToolBox. Get Price And Support Online; Bulk Material Density Guide Hapman. You need to know bulk density to work with any powder or bulk solid.

Example Calculations

Determine the void ratio of a saturated soil sample that has a mass of 178 g before drying and 139 g after drying in an oven. Assume the specific gravity of the soil solids to be For a saturated soil S r = 1 Void ratio, e = m × G s = × =

Properties of porous concrete from waste crushed concrete ...

aggregate on total void ratio, strength and permeability was examined. Styrene butadiene rubberbased redispersible polymer powder and latex were introduced to mixtures to improve strength properties. The total void ratio of porous concrete incorporating recycled aggregate was larger than that of porous concrete with normal aggregate.

(PDF) On active and inactive voids and a compression model ...

The void ratio of this packing can be reduced to its Based on this postulate, we derive a mathematical equation that ex densest state, due to the kinematic process of particle rearrangement. presses void ratio in terms of effective stress and initial void ratio of the The densest packing structure for a monosized group of spheres corre material.

Porosity of crushed rock layer and its ... SpringerLink

It has been proven that crushed rock layers used in roadbed construction in permafrost regions have a cooling effect. The main reason is the existence of large porosity of the rock layers.

Concrete Mix Design By Packing Density Method

The bulk density, packing density and voids ratio are plotted against the mass fraction of coarse aggregate are presented in the Figures 4, 5 and 6 respectively. From the Fig. 4, 5 and 6 maximum bulk density gm/cc, maximum packing density gm/cc and minimum voids content is

How to Calculate the Volume of Voids | Sciencing

Apr 24, 2017· A void is the volume of space in a material such as sand or gravel not occupied by particles. The volume of voids is made up of tiny gaps between particles of the material. Calculating the volume of voids can be complex, requiring hightech tools such as measuring lasers. In other situations, like the one described ...

void ratio of crushed stone

Voids in coarse aggregates: An aspect overlooked in the ACI Мб. .. OA 05 void ratio of coarse aggregate void ratio of coarse aggregates Figure I. Effect of variation of coarse aggregate Materials In Bangladesh, crushed brick, an indigenous material, is widely used as coarse aggregates because of scarcity of natural stone aggregates.

Infiltration trenches LID SWM Planning and Design Guide

Gravel used for underdrains in bioretention, infiltration trenches and chambers, and exfiltration trenches should be 20 or 50 mm, uniformlygraded, clean (maximum wash loss of %), crushed angular stone that has a void ratio of

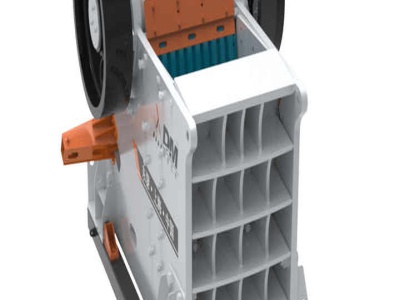

Design and Flow of Powdertype SCC with Crushed Aggregates

Jul 29, 2010· A test vessel has been designed which enables the determination of the void ratio of the aggregate and the necessary paste volume. The method has been applied to various aggregate (crushed quartz porphyry, crushed muschelkalk, gravel, fluvial sand).

Chapter 3 Conclusions and Recommendations for Research ...

A maximum surface void ratio of % and maximum sur face void diameter of 3â 8 in. (, CSC 3) were observed on all formed surfaces of the fabricated SCC bridge components. A lower surface void ratio can be achieved by controlling the direction of flow so that it is bottomup rather than topdown, further reducing the entrapped air during ...

Optimization of Concrete by Minimizing Void Volume in ...

Fig. 14 shows the evaluated void ratio from the experiments using mixtures of both natural sand (02 mm) and crushed rock (Kåll. 02 mm). The blue curve represents the presently proposed model for this a minimum void ratio ofwhen the natural sand ratio is45% in the mixture.

HOME >> Product >>density of crusher stone dust

Crusher Dust, Crushed Stone Aggregate, CBR, Void Ratio. . compaction curve it can be seen that crusher dust attains higher densities with wider variation in. Crushed stone Wikipedia Crushed stone or angular rock is a form of construction aggregate, typically produced by mining Crushed stone has one of the lowest average by weight values of all ...

Aggregates for Concrete University of Memphis

Crushed stone is produced by crushing quarry rock, boulders, cobbles, or largesize gravel. Crushed aircooled blastfurnace slag is also used as fine or coarse aggregate. The aggregates are usually washed and graded at the pit or plant. Some variation in the type, quality, cleanliness, grading, moisture content, and other properties is expected.

The Constructor Civil Engineering Home

The Constructor Civil Engineering Home provides informational resources to Civil Engineers on subjects such as concrete, construction, Structures, Building Tips, How to Guides.

PolymerModified Mortars And Concrete Mix Design

PolymerModified Mortars And Concrete Mix Design ... Fine and coarse aggregates such as river sand and gravel, crushed sand and stone, silica sands and artificial lightweight aggregate recommended for ordinary cement mortar and concrete, are used for latexmodified mortar and concrete. ... Simultaneously the bindervoid ratio to satisfy the ...

Porosity and Bulk Density of Sedimentary Rocks USGS

percent for a depth range from 1,000 to 5,000 feet, but Hedberg's data (1936) for undisturbed Tertiary shale show an average porosity of percent for a depth range from 219 to 7,994 feet. Tabulations of the assembled data on porosity and bulk density follow (tables 15).

Latest Posts

- كسارة حجر الغرانيت 50 tph

- مصنع الفضة المطاحن والكسارات كاملة

- harga alat vs kapasitas كسارة فكية

- سحق الاسمنت في المطاحن الكروية

- محطم الصناعية في مصر

- عالية الكفاءة علي بابا الصين مطحنة الكرة الذهبية

- طحن الكرة عملية الصب

- إنتاج الرمل المصنعة خط

- تنظيف المعدات

- جد كسارات صخور منخفضة السعر للبيع في مصر

- التعدين محطم تصميم محطة

- بيع كسارة مطحنة طحن

- أنظمة تكسير كاملة

- تأثير مطحنة لغرامة الفيديو

- قائمة harga mesin pemecah batu كسارة الحجر

- pumps for refining bauxite

- concrete crusher manufacturers mobile crushers all over the

- how to levelling surveying

- processes of iron mining

- crusher plants auction

- where to buy a mercury retort in australia

- tirupati plant make sic crystal wafer

- cement clinker for sale

- cylinderical ball mill worldwide

- fcb mill installed in tunisia ciok

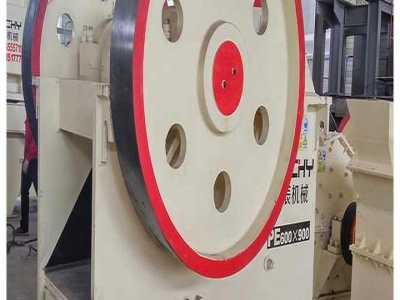

- stone crusher machinery equipment

- production of cement vertical mill manufacture saudi

- amature gold ore crusher

- temdo maize mill grinding machines

- shingle pro xl 406 portable grinder