cement ball mill grinding

Grinding Equipment_ZK Ball Mill_Cement Mill_Rotary Kiln ...

Ball Mill for Raw Meal Grinding:Raw meal ball mill has features of various materials application, continuous running, big grinding rate, easy control of product fineness. 2. Vertical Mill for Raw Meal Grinding:In the process of Dry Type Cement Production Line, Vertical Mill is mainly used for raw meal preparation.

Ball Mill_Cement Mill_Cement Kiln_grind mill_rod mill ...

Ball Mill,Cement Mill,Cement Kiln,grind mill,rod mill,rotary kiln supplierChina Henan Zhengzhou Mining Machinery Co. Ltd. We offer you firstclass equipment and mature production line solutions.

What does a cement plant of the future look like? (Part 2)

Dec 01, 2017· 3) The cement mill grinds the clinkers to an appropriate heat to produce cement. Each step is critical but the final step is where the magic happens. Grinding to perfection. In the final step, the cement mill grinds the clinkers using horizontal ball mills. The ball mill has two rotating chambers with ceramic balls that grind the clinkers.

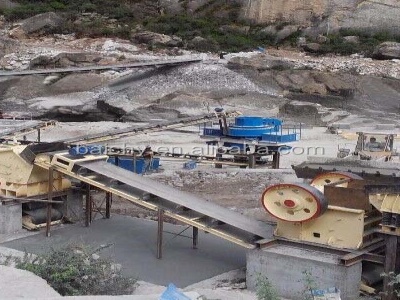

Project for "Cement Australia" in Port ...

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations ...25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding ...

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

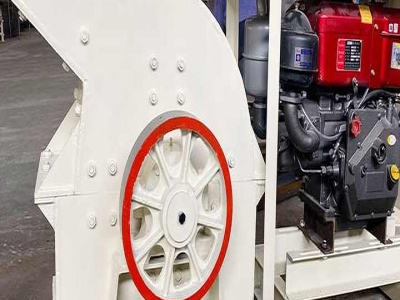

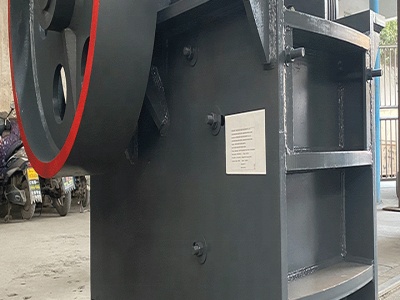

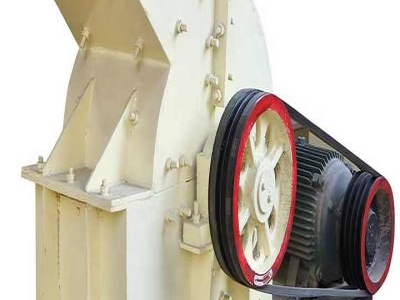

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

Ball MillFTM Machinery

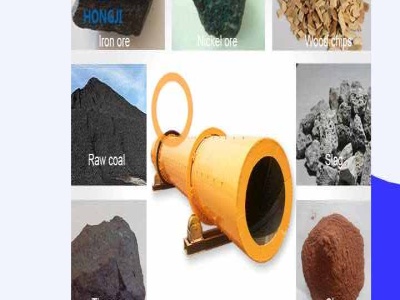

Ball mill is a key equipment to recrush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 new building materials, refractory materials, fertilizer, ferrous and nonferrous metals and glass ceramics and other production industries.

cement ball mill grinding internal photo

effects of grinding media shapes on ball mill performance. grinding. Ball size distribution inside an industrial mill was analysed in terms of ... emitting diode, phototransistor and video photographs were used to determine ..... processing, cement production, power plants and .

FCB Bmill Fives in Cement | Minerals

The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals. Benefiting from a large experience, the FCB BMill has been designed to be particularly well adapted for the grinding of products at high fineness and grinding of very abrasive ...

cement grinding ball mill design

Cement Grinding Ball Mill Design cement ball mill ball charge design, Cement mill grinding media charging book, 13 Feb 2016, The work horse of the cement grinding plant is the two,how to . Contact Supplier cement ball mill design pdf pakistan stone crusher .

calculation for grinding media for cement mfg by ball mill

Cement grinding is the single biggest consumer of electricity in the manufacturing process. ... o For ball mills, only 3 6% of absorbed energy is utilized in surface production, the heat generated can increase mill temperature to > 120⁰ C causes excessive gypsum dehydration media coating if mill ventilation is poor.

Grinding trends in the cement industry Cement Lime Gypsum

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

Grinding Aids for Ball Mills | Industrial Efficiency ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the mill liners or grinding media as coating, reducing the impulsive force of the mill. In addition, the agglomerated particles are mixed into the coarse powder in the separator and recirculated through the mill.

Forged And Casting Ball Mill Balls Mining And Cement Steel ...

Low breakage Forged Grinding Ball 20130mm 45# 60Mn B2 B3 Material forging steel balls. High impact value steel grinding ball / grinding media steel balls Dia 20150mm. Ball Mill Balls. Performance Grinding Balls For Mining / Professional Grinding Media Balls. High Performance casting steel grinding Ball Mill Balls for cement plant

grinding media of ball mill used for cement manufacturing

Optimization of Cement Grinding Operation in Ball Mills... cement grinding operation amounts to one third of the total electrical energy used for the production of cement. ... Optimization can also reduce the cost of liners and grinding media. ... Cement ball mills typically have two grinding .

Industrial Solutions polysius ball mills

ball mills, but also from our comprehensive scope of services, ranging from maintenance and OEM spares procurement to the optimization of existing plants. The grinding unit most commonly used for grinding brittle materials, such as cement, is still the ballfilled ball mill. The following types can be found: • singlecompartment mills,

grinding mill,ball mill,crusher,raymond mill,rotary dryer ...

Mining news Advantages and Benefits of Magnetic Separator. Magnetic separator machine is suitable to separate magnetite, pyrrhotite, roasted ore, ilmenite and .

Stone Powder Grinding Machinegrinding mill/ultrafine mill ...

HGM series stone powder grinding machine is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so purpose of the micro powder grinding mill is for superfine grinding materials with hardness less than 6 in Moh's scale and .

clinker ball mill for cement grinding plant

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Mineral Grinding Mill |

Mineral Grinding Mill Supertech Grinding is a leading Manufacturing, Exporting and Supplying superior quality range of Mineral Grinding Mill. SuperTech Grinding Unit. ... Cement Plants, Ball Mills, Roll Crusher, Jaw Crusher, Grinding Unit Rotary Drayer, Rotary Kilen, Clinker Grinding Unites and Screw Conveyor. Grinding Unit and its Components.

Mill (grinding) Wikipedia

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, drawing approximately % of the total world's power (see List of countries by ...

Latest Posts

- مخطط تدفق مطحنة الخام في مصنع الأسمنت

- خط إنتاج سحق

- الحديد إثراء خام اقتراح

- المعدات الذهب تكرير مصنع آلة

- حجر آلة محطم المبدأ

- الرمل الناعم المورد طاحونة المملكة العربية السعودية

- تهتز الشاشة استخدامه في مصنع النيكل

- الكسارات لبنة للبيع في العراق

- المورد الرئيسي لآلات التعدين في المغرب

- معدل ضريبة القيمة المضافة على آلة التكسير في مصر

- تستخدم كسارة مخروط الحديد الخام في المملكة العربية السعودية

- لوازم التكسير والتعدين الليبية

- المسار شنت الكسارات الفحم السودان

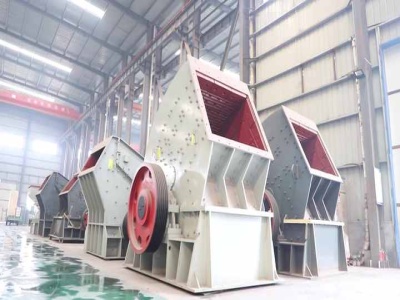

- تأثير محطم الموردين من الصين

- عملية طحن لا مركزية ملف pdf

- ppt on stone crusher

- aluminium copper wire rolling mill plant aluminium wire rolling mill plant

- ebay tangan dioperasikan jaw crusher

- apparatus required forcalcination of limestone at 900 degree

- copper procesing plant dubai and uae

- symon lube system

- rock crushers specification

- istambul stone mill

- vibro screen manufacturer in india

- cordless grinder machines in india

- iron ore crushing plant iron ore crusher iron ore crushing

- large surface metal grinding machine portable

- grinding machine vendor in china

- introduction milling machine

- grinding mill for coal fired power station