how to take material out of ball mill

Theory and Practice for

When mills are rotating at too fast a rate, centrifuging will occur. Individual media are thrown clear of the media mass and move independently until they rejoin the charge at the bottom of the mill. Unground material is held with the centrifuging balls and result in uneven disintegration or dispersion.

Ball Mill From Mainly Recycled Parts: 11 Steps

You should be able to find how to get it out by yourself but i will do my best to talk you through it. 1.) Turn the machine over and locate the screws on the bottom. (may be on side or back for different models.) 2.) Take the screws out and unbolt the motor from the bottom panel and remove the panel. 3.)

What is a Ball End Mill?

A typical ball end mill will often be manufactured with a protective coating. These coatings usually contain titanium mixed with other elements such as carbon and aluminum . The coatings are applied to reduce wear and friction, and can also prevent damage to the cutting surface.

EXPERIMENT 2: BALL MILL GRINDABILITY TEST WAN .

4. Later, take the sample that have been split and placed in a measuring cylinder up to 700ml packed. The weight of the measuring cylinder with the sample were measured. 5. The sample then was placed in the ball mill to be grind. The starting revolution use was 150rpm. 6. After that, the mill was emptied and the ball mill charge was screened out.

How To Choose an Endmill Mastercut Tool Corp

Ball End: The tip of the tool is rounded or in the shape of a halfball. These endmills are used to mill die cavities and fillets, round bottom holes and slots. These endmills are used to mill die cavities and fillets, round bottom holes and slots.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ... The process diagnostic study for ball mill optimisation is carried out in following steps depending on the ... The maximum power point is dependent upon the feed material characteristics, mill liner conditions, grinding media charge and ...

Making a Ball Mill YouTube

Mar 31, 2018· The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make i... Skip navigation Sign in

Highenergy ball milling technique for ZnO nanoparticles ...

Apr 29, 2011· The major use of the conventional ball milling is to fracture the particles and to reduce the size, which is different from the newly established high energy ball milling (HEBM) method. In this new method a magnet is placed close to the cell to apply a strong magnetic pulling force on the magnetic milling balls, and therefore the impact energy is much higher than the conventional ball milling energy.

How to ensure energy efficiency in mining 3/4: Achieving ...

Dec 18, 2018· In order to maintain throughput, a VTM1250 was installed semiparallel with the existing ball mill circuit. The VTM1250 accepted undersize from a new screen installed on a portion of the ball mill circuit's hydrocyclone underflow. This allowed the ball mill to focus on coarser material while the Vertimill finished the grind on the finer material.

Ball mill Chemistry Dictionary Glossary

Oct 20, 2018· Ball mill is a grinder for reducing hard materials to powder. The grinding is carried out by the pounding and rolling of a charge of steel or ceramic balls carried within the cylinder. The cylinder rotates at a relatively slow speed, allowing the balls to cascade through the mill base, thus grinding or dispersing the materials.

Mechanical milling of aluminum powder using planetary ball ...

Therefore, the milling media and the charged powders alternatively roll on the inner wall of the vial, and are lifted and thrown off across the bowl at high speed. One advantage of this type of mill is the ease of handling the vials (45 ml to 500 ml in volume) inside a glove box. a) b) Fig.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

The ball mill jars. Place the outer cap on the jar and push it downwards. The taper on the outer cap pushes the jar's top edge inwards slightly, crimping it inward around the inner lid. Put the washer onto the threaded stud. Screw the nut on snugly, but just tight enough to hold the outer cap on securely.

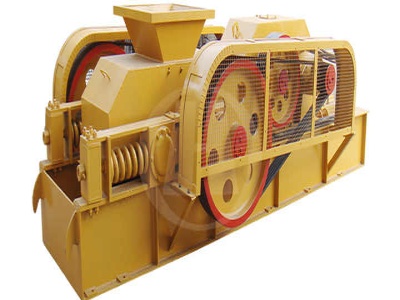

Raw Material Ball Mill

Overview. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries.

How to Grind Granular Potassium Nitrate with a Coffee ...

Granular potassium nitrate can be dried if necessary, and ground easily with a ball mill or with a coffee blade mill, so that it passes through a 100mesh screen and is ready to be used in pyrotechnic compositions. Materials Needed. Potassium Nitrate, prilled (ZCH5302) Coffee/Spice Grinder

Ball Mill Manufacturers Suppliers | IQS Directory

Continuous ball milling involves the ongoing automatic loading of materials to be crushed and unloading of crushed materials. Depending on the scale of the milling operation, ball mills can be small enough to fit on work benches or large enough to take up entire rooms.

Raw Material Preparation

Typically the ball mill was placed on an upper floor so that material could move by gravity. An example was the original rawmill system at Aberthaw. Four Ernest Newell ball and tube sets were provided to serve two kilns. The ball mill by this stage used forged steel balls as grinding media and had its outlet in the form of grids in the end wall.

Latest Posts

- قائمة من الخرسانة السائلة الكيميائية كسارة

- ألواح الجبس وخط إنتاج مسحوق الجبس

- سحق بني وتأثير الجزائر

- صنع الرمال من كسارات

- توفير الطاقة مطحنة الكرة قضيب من آلات yigong

- استخراج معالجة الحديد باستخدام مخطط انسيابي

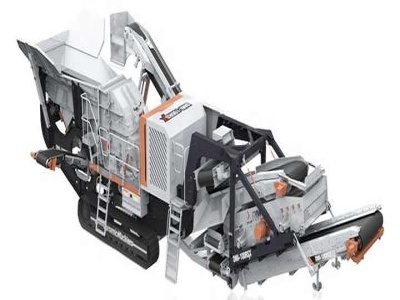

- معمل متنقل للتأجير

- سعر آلة تصنيع مسحوق في كولكاتا

- كسارة الحجر الصغيرة في الولايات المتحدة الأمريكية

- المعلمات عملية لخام الحديد تهز الجداول

- معدات الفحص الكلي في الاردن

- كسارة مخروطية cs في ألمانيا

- غسالة رمل البنتونيت

- قائمة كسارات الحجر في ضاحية كنياكماري

- الصخور مختبر آلة طحن في مصر

- limestone crushers in ghana

- used iron ore machinery swedenri

- peralatan yang digunakan di tambang batu bara

- rail costs brazil iron ore

- free project on ready mix concrete in pdf file

- vsk kiln for sale

- impact crusher on tracks

- usa crusher machine

- bellary m sand contect number educationcare in

- sand milling and silica sand effects

- blastrac bgs capacitor wiring diagram

- thu used pendulum roller mill usa

- free ebooks in pakistan lahore

- stone crusher plant electrical explanation

- promotional steel ball crusher