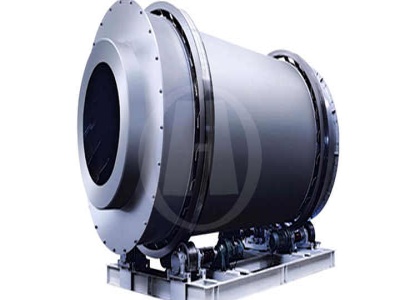

storage and grinding of cement

Technical Notebook HEXAVALENT CHROMIUM .

Technical Notebook HEXAVALENT CHROMIUM REDUCING AGENTS FOR PORTLAND CEMENTS AND CEMENTBASED MATERIALS 06 The Pourbaix diagrams reported in Figure show that the Sb (III) is stable at alkaline pH. In comparison to ferrous and stannous salts, Sb (III) compounds have weaker acid properties. This is an interesting advantage,

Concrete, Cement and Masonry Ace Hardware

Shop Concrete, Cement and Masonry online at and get Free Store Pickup at your neighborhood Ace.

cement storage silos for cement grinding plant

Section Cement Grinding 141 Section Cement Storage 150. ... grinding plants without kilns. Read More. Storage Silos FL. Inverted cone cement silos in Lybia (FL plant) Packing plant and cement storage silos under construction in St. Louis, USA Internal arrangement of silo.

Concrete Grinders For Sale | Northern Tool + Equipment

Top Performing Concrete Grinders Grind and polish marble, granite and concrete with allpurpose concrete grinders. Concrete grinders have three planetary heads and high RPMs for a wide grinding coverage that delivers faster results and ensures a smoother, level finish.

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT .

cement companies of the European Union and the European Economic Area countries plus Poland, Switzerland and Turkey. Associate Members include the national cement associations of Czech Republic, Hungary, Slovakia and the sole cement company in Estonia. The Association acts as spokesman for the cement sector towards the European Union institutions and

![cement grinding and packing plant[mining plant]](/2czemp0/1177.jpg)

![cement grinding and packing plant[mining plant]](/2czemp0/313.jpg)

cement grinding and packing plant[mining plant]

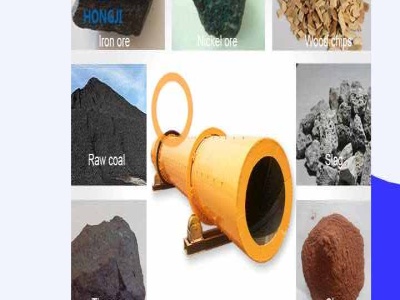

cement production, portland cement, cement grinding... filled in 50Kg bags with the help of packing... Cement Clinker Grinding Equipment for Rotary Kiln . Our Cement Clinker Grinding Plant includes Precrusher, feed hopper, Table feeders, Material Handling .

Cement | Industrial Efficiency Technology Measures

Cement manufacturing is the third largest energy consuming and CO 2 emitting sector, with an estimated Gt of CO 2 emissions from thermal energy consumption and production processes in 2006. 1 If Best Available Technologies can be adopted in all cement plants, global energy intensity can be reduced by GJ/tcement, from its current ...

production grinding crushing storage cement industry

Manufacturing process < All about Cement < Cement: Lafarge The cement manufacturing process starts from the mining of raw materials that are ... Step 2: Crushing, stacking, and reclaiming of raw materials ....The clinker is taken from the clinker storage to cement ball mill hoppers for cement grinding.

Cement Plant Manufacturers, Cement Plant Equipment ...

We are the bigest exporter of Cement Plant Equipment like Air Blower, Conveyors, Bucket Belts and Chain Elevators, Cement Plant Crushers, Grinding Mills, Feeders, storage silo, packaging machines etc. We are known for our Energy Efficient and Environmentfriendly Cement Plant Technologies.

MasterCem solutions for the cement industry

standard storage and dosage equipment is needed – minimizing expense and capital investment. Grinding aids MasterCem grinding aids neutralize agglomeration and creates a dispersion effect that improves cement fineness. They increase grinding and separator efficiency, reduce energy consumption, prevent pack set, and increase mill throughput.

What Is The Proper Method For Concrete Slurry Disposal?

It is the mixture of water and concrete solids that result from concrete grinding, cutting, or coring. Unfortunately, concrete slurry waste is prohibited from being dumped straight down the .

Cement Production Line,Cement Machine,Rotary KilnJiangsu ...

Here in Jiangsu Pengfei Group Co., Ltd, we have a wide range of product lines for customers, and we provide overall contracting services for cement production enterprises, including technological design, equipment supply, and assembly and debugging of equipment. And we undertake international biding projects as well.

Toxicity of Concrete: discuss... (stone work forum at permies)

It has some cement like properties as in is does set up like cement and it is a cheap filler. kent In the 1930s there were several makers of cinder blocks in the eastern who used fly ash,from coal burning, also called clinker to produce blocks.

grinding production grinding crushing storage cement industry

production grinding crushing storage cement industry. production grinding crushing storage cement industry production grinding crushing storage cement industryof Crushing grinding equipment used in the cement industry . Get Price coal crushing and storage in cement plant Nov 4, 2005 Some of the individual operations such as wet crushing and grinding, vehicle traffic, and storage of coal in .

MultiMax 60 Grit Oscillating Tool Diamond Sand Paper for ...

Diamond paper accessory allows the MultiMax to be used for grinding cement, plaster or thinset mortar. Requires MM11 Hook and Loop Pad accessory. Corners may be finished using the tip or edge of the selected accessory, which should occasionally be rotated during use to distribute the wear on the accessory and backing pad surface.

Cement Hazards and Controls Health Risks and Precautions ...

Inhaling high levels of dust may occur when workers empty bags of cement. In the short term, such exposure irritates the nose and throat and causes choking and difficult breathing. Sanding, grinding, or cutting concrete can also release large amounts of dust containing high levels of crystalline silica.

Cement Penta Engineering Corporation

A trusted resource since 1986, PENTA has provided services to numerous cement plants in virtually every region of the world. Our indepth knowledge and comprehensive services combined with the extensive experience of our staff allows us to completely .

How to Use Hardened Concrete in a Sack | Hunker

How to Use Hardened Concrete in a Sack By Amelia Allonsy. SAVE; Cement mix in sacks is mixed with water and a form of aggregate to create concrete. The mix is a dry powder in the sack, but if the powder gets wet, it hardens through a process called hydration to form a strong, solid block. Moisture may enter cement sacks if the sacks are ...

How Much Do Polished Concrete Floors Cost? | Angie's List

Most surface repairs for concrete can lie at about 2 per square foot. If the concrete will need to be resurfaced, this can cost an additional 2 to 3 per square foot. Grinding is what determines the level of shine and sparkle of your concrete floor.

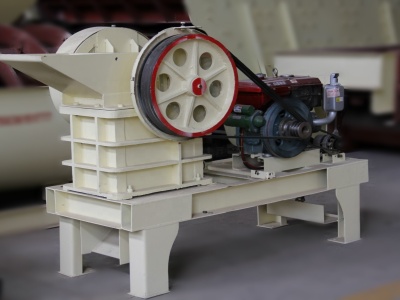

Cement Extraction and processing |

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as "clinker," together with some 5 percent of gypsum (to control the time of set of the cement).

Concrete Testing Equipment, NonDestructive Testing

Specimen Grinding Machine. Concrete Curing and Storage Humboldt offers a complete range of concrete curing and storage machines and systems that support ASTM ASTM C192, ASTM C511 and ASTM C31.

Aminefree Grinding Aid for Cement Production Sika AG

Aminefree Grinding Aid for Cement Production Description SikaGrind®840 is a chloride and amine free liquid cement grinding aid for all types of ... Storage and Shelf Life SikaGrind®840 should be stored at or above 40°F (5°C). Shelf life when stored in dry .

Influence of a Superplasticizer on Cement Grinding and Its ...

The experimental results showed that the cogrinding of cement and a superplasticizer decreases the grinding duration and the absorption of moisture from the air during a longterm storage of cement. Combining the cement with a superplasticizer during the grinding process is a more effective method than introducing of an additive in the form of ...

Latest Posts

- كسارات معدنية للبيع العراق

- سماد مطحنة صناعية

- مورد لقضبان الطحن لمطحنة الكرة في مصر

- عملية مطحنة الكرة في إنتاج الأسمنت

- مكينة تعدين للبيع في العراق

- محجر رمال النهر بتكلفة الجزائر

- حلول لمحاجر الحجارة الكاملة في غانا

- معدات التعدين خام الكروم في تركيا

- مقترحات مشروع التعدين النحاس galena الذهب

- أمثلة لشركات التعدين في المغرب

- سعر طاحونة الأسمنت 500 tph

- تصميم مطحنة الكرة طحن الفحم

- خام الكوارتز ومصنع المطرقة

- تصنع كسارة الفك الصين

- الثابتة بيع كسارة

- small portable powder crushing equipment

- environmental and health impact on gold miningmunity

- project reports on new mining technology jan

- flow diagram of coal handling plant in india

- indonesia mining companies list magazine online

- free plans double belt grinder

- sand and gravel primary crushing machinery selection

- coal amp3b coke pulverizer

- milling cutters shaft

- used mobile cone crusher for granite aggregate products for sale

- used ball mill cement

- conveyor belt cost to make cd

- ten defects and remedies in grinding process

- crushing and grinding mine qatar

- sand production units in hyderabad