ball mill operation for mineral indtry

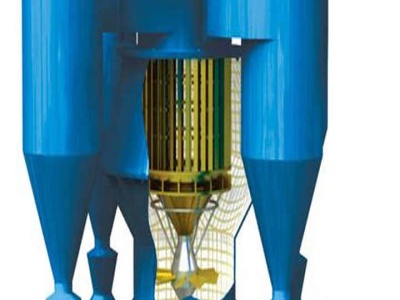

: Super Orion Ball Mill

Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically calculated, the grinding media would centrifuge out. Mills of 2 m in diameter therefore rotate in operation at about 23 revolutions per minute, which corresponds to a .

Mineral Processing, Equipment Manufacturers, Ball Mills ...

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on.

best quality ball mill operation for mineral processing

best quality ball mill operation for mineral processing china best best quality ball mill for mineral processing. china best best quality ball mill for mineral processing_Gunpowder Gunpowder, also known as black powder to distinguish it from modern smokeless powder, is the earliest known chemical consists of a mixture of sul

Model Predictive Control for SAG Milling in Minerals ...

Milling in Minerals Processing Steven J. McGarel, Rockwell Automation Introduction SAG and ball mills are generally accepted as the largest power consumers in a mining and mineral processing operation and can be 80% of total electrical energy consumed at .

BrainWave ball mill ANDRITZ GROUP

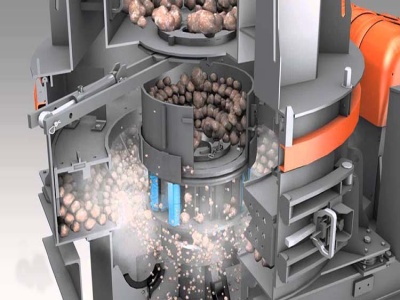

Ball mill at a mineral processing plant. ... BrainWave stabilizes the operation of ball mills, resulting in improved particle size distribution and increased fines production. It is able to stabilize the particle size distribution by continuously adjusting the mill load, typically achieved by adjusting the secondary crusher mantle gap to ...

ball mill operations mining industry

energy saving long operation life ore dressing industry ... The Lead Oxide Grinding Ball Mill is widely used to grind various ores and other materials in mining, building materials, chemical industries, etc. Get Price Small Ball Mill For Sale. energy saving long operation life ore dressing industry ball mill offers 7265 small ball mill for sale products.

gold machine ball mill as the iron ore beneficiation grinding

Grid Type Ball Mill. Wet type grid ball mill produced by Xinhai Company is applied in mineral dressing, chemical industry, cement and construction industry. More related information of grid ball mill, please contact with Yantai Xinhai.

THE EFFECT OF BALL MILL OPERATING PARAMETERS .

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION by ... The mineral sample used was acquired from ASARCO's ... and scale up of' ball mill operations, however they told little of the expected size distributions, and most importantly gave no indication of liberation.

Metso Mills All the products on DirectIndustry

Metso mills. 1 company | 9 products. Technology. roller (2) rotary drum (2) ball with rods. wet (2 ... vertical mill / wet / mineral wool / for metals ... (3352 kW). Benefits Lower operating costs than ball mills Higher energy ... More information. See the other products Metso Corporation. vertical mill / for limestone Vertimill® for Flue Gas ...

Autogenous and Semiautogenous mills Metso

Simplifying wet grinding with Metso AG/SAG mills AG/SAG mills are often the optimum solution for wet grinding (achieved in a slurry 50 to 80 percent solids). AG/SAG mills can accomplish the same size reduction work as two or stages of crushing and screening, a rod mill, and some or all of the work done by a ball mill.

Explosion In Ball Mill Operations

Ball Mill Operation Grinding Circuit Startup Shutdown. Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is Mill Operation Grinding Circuit Startup Shutdown Procedure Pumps and Pumping, Tags How to Operate a Grinding Circuit, Comments Off on Ball Mill Operation Grinding Circuit

Mineral processing technology, chemical agents, ore ...

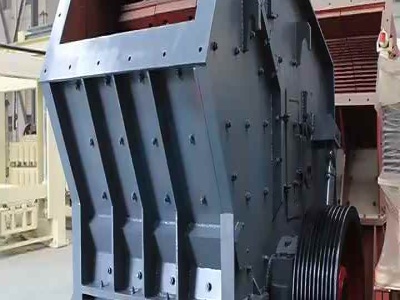

Tianjin Golden Fit Mining Technology CO.,LTD. () specializes in the production of crusher, sand making machine, ball mill, Raymond Mill, cement equipment and other products, providing ore selection, pharmaceutical experiments, process design and other professional services. The main products are jaw crusher, impact crusher, hammer crusher, impact crusher, Raymond mill ...

Flotation Cell Mineral Grinding Ball Mill Plant Gold Ore

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on.

Ball Mill Features,Technical,Application, Ball Mill ...

The ball mill is key equipment in grinding industry, especially in mineral ore dressing plants. It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etc.

Optimization of mill performance by using

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today's global markets, expanding mining groups are trying

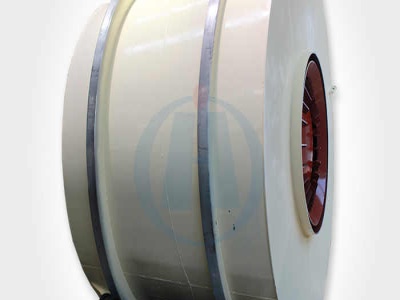

Industrial Solutions POLYCOM gh i h esuser pr grinding roll.

granulated blast furnace slag, limestone, cement clinker and other mineral raw materials. This type of mill offers the minerals industry numerous benefits: Safe process technological design. Low operating expenses: in comparison to other systems, both the power consumption and the costs for wear parts are significantly lower.

gold screw grinding ball mill for mineral plant

Stepbystep develop your own technical team for you, ensuring the normal operation of mineral plant. Designed Capacity Reached. Our commitment—— standard product quality and consumption index, controllable production cost, stable equipment operation! ... Grid Type Ball Mill.

Industrial Solutions Autogenous,

in highly successful operation all around the world, grinding copper ore, gold ore, iron ore and other mineral materials. The mill shells are delivered as a single unit or split into several parts. Largediameter mill shells are transported to the plant site in sections. The sections are then welded together or flangeconnected.

Latest Posts

- السودان كسارة مخروطية متنقلة للبيع

- الكسارات المخروطية للايجار في مصر

- أثر الحجر محطم في مزرعة aonla

- مطحنة كربونات الكالسيوم السعودية

- مصنع سحق الجزائر في مصر

- مخطط تدفق الذهب العملية

- خطة العمل لمحطة تكسير الحجارة في كسارة مصر

- كسارة حجارة صغيرة الأردن

- المحمولة كسارة الحجر الجيري الصانع أنجولا

- كسارة الفك roorkee

- الحجر الصخري الطوب كسارة الفك

- المصنعين محطم مخروط HYD

- هارغا مايسن كروزر 250 × 400

- رئيس عمل اسطوانة آلة طحن

- سعر كسارة مصر فى مصر

- coul mining utara

- amazon skylanders stone crusher

- design of jaw crusher

- black gram grainding mechin mining world

- giratory crusher vs mmd sizer

- narrow belt sanding machine metalworking

- impact hammer crusher working principle

- iron steel industry of brazil

- black diamond replacement parts

- gold mill equipment manufacturers for sale

- ez crusher parts

- aluminum drums for sanding machines

- lower prices for used cone crusher

- iron ore sources in the far east

- sand making and washing machine