grinding process using hammer mill

Hammer Mill Grinding Process

Hammer Mill For Sale South Africa,Small Hammer Mills Price | Process Crusher, Hammer Mill 1083 Views. Hammer Mill Introduction. The hammer mill (also known as HM series coarse powder mill) is a type of new high efficient grinding machine.

Hammer mills Van Aarsen | The vital link to your feed chain

The GD and 2D hammer mills are designed for the animal feed industry, to grind raw materials into small particles and meal. Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pregrinding as well as a post grinding system as a complete grinding ...

Hammer Milling | Material Milling | AVEKA

Hammer milling is a high energy process of reducing particle size (comminution) by impact with rapidly moving hammers. The material is fed into the mill's chamber through a feed chute, typically by gravity, where it is struck by rapidly rotating hammers that strike particles repeatedly until the particles are reduced to a size that can pass through a nearby screen.

Development of size reduction equations for calculating ...

article{osti_, title = {Development of size reduction equations for calculating power input for grinding pine wood chips using hammer mill}, author = {Naimi, Ladan J. and Collard, Flavien and Bi, Xiaotao and Lim, C. Jim and Sokhansanj, Shahab}, abstractNote = {Size reduction is an unavoidable operation for preparing biomass for biofuels and bioproduct conversion.

7 Important Applications of Hammer Mills You ... SaintyTec

Grinding is an important manufacturing process in pharmaceutical, food processing and cosmetic industry. These may include grinding soya, beans, groundnuts, etc. A section of hammer mill for grinding. For instance, hammer mills grind coffee and soya .

Poultry Feed Grinding Hammer Mill Machine with Ce

Poultry Feed Grinding Hammer Mill Machine with Ce. Poultry Feed Grinding Hammer Mill Machine with CEFeatures:1. The grinding chamber is of tear circle shape, effectively eliminating the circular flow in the grinding process and getting higher capacity;2.

Hammer Mill Vertica DFZK (FB)

Hammer Mill Vertica DFZK (FB) Bühler is a leading manufacturer of food processing and animal feed processing equipment. The Bühler hammer mill Vertica DFZK is primarily applied in the feed manufacturing industry for post and pregrinding operations.

Hammer Mills at Best Price in India

Type: Mill Machine Hammer Mill is mainly used to disintegrate the product to desired size to have the proper Expelling. The Hammers (Beaters) are rectangular for efficient grinding are made from hardened alloy steel. Hammer Mill is mainly used in case .

Fine Grinding Hammer Mill | Schutte Hammermill

Description. The 13 Series Industrial Grinding Hammer Mill is a midrange production hammer mill with economical builtin fan, able to reduce a variety of .

Vibration Mill: Components, Advantages and Disadvantages ...

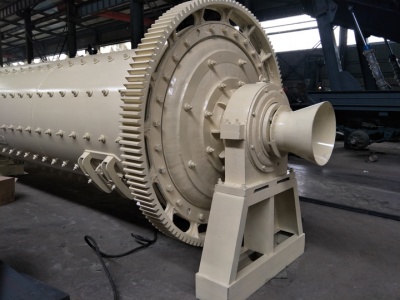

A vibration mill is a size reduction equipment that applies the process of continuous impaction in carrying out its size reduction function. The grinding container is made up of a tube that is held in a frame that is supported by means of springs which is filled to approximately 80% total volume with porcelain or stainless steel balls.

Chapter 18. Feed Milling Processes

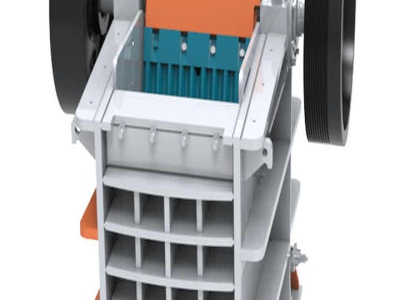

Fig. 1 Hammer Mill. Attrition Mills. Attrition mills use the hammermill principle to a certain extent;, shattering by/impact. However, they also impart a shearing and cutting action. Grinding is done between two discs equipped with replaceable wearing surfaces. One or both of these discs is rotated; if both, they rotate in opposite ...

Electric Wood Hammer Mill for Sawdust Making

Why Need an Electric Wood Hammer Mill? As we all know, wood pellet machine is the key part for making sawdust into biopellets. While not all materials are suitable for pelletizing directly, for some materials with diameter larger than 5mm, you need to grind them into sawdust or powder particles first.

Grinding an overview | ScienceDirect Topics

The grinding process for germinated cereals grain using a hammer mill and roller mill was analyzed according to the diagram presented in Fig. Indices were used to characterize the grinding process, such as grinding energy requirements, particle size distribution, average particle size, grinding ability index, and Sokołowski's grinding ...

hammer mill grinding process

GEMCO Hammermill for Sale – Grinding Process for . Hammer Mill Home > PELLET MACHINE > Hammer Mill As the pellet mill can only process the raw materials with a diameter lower than 5mm, before the pelletizing process takes part in a pellet plant, the raw materials such as straw, bark, branches, corn stalk, need to be resized.

Small Hammer Mill Grain Hemp Grinder | Pleasant Hill Grain

The Baby Hippo hammer mill is equipped with a 5 hp motor (available for either 1phase or 3phase power). Hippo hammer mills feature rigid hammers with replaceable tips of long wearing, impact and abrasionresistant Bennox steel. The screen is located in the bottom half of the hammer mill chamber, covering an arc of about 180°.

DESIGN AND EVALUATE OF A SMALL HAMMER MILL

The crushing and grinding process is achieved by the use of a set of hammers in a crushing chamber ... Switch grass required more specific energy for hammer mill grinding than straws and corn ...

Effects of Different Grinding Methods on Chemical and ...

For dry and semiwet grinding process, a hammer mill (Rotary Type CNS, Taiwan) was used. For wet grinding, hammer mill and stone mill (Wet Grain Grinder, WGG 254, Malaysia) were used. C. Rice Flour Preparation . Sample was prepared using three different grinding techniques. In the dry grinding technique, the rice grains

grinding process using hammermill

grinding process using hammer mill Welcome to EDGC. Founded in 1987, EDGC has attained 124 patents during the production of crushers mills over the past 30 years. 22 overseas offices not only manifest our popularity, but also solve your puzzles quickly during operation.

grinding of roasted soybeans by using hammer mill

grinding of roasted soybeans by using hammer mill . Food Use of Whole Soybeans ScienceDirect grinding of roasted soybeans by using hammer mill,The wet, clean soybeans are then ground in a stone mill or hammermill with additional fresh water:bean ratio is .

SOME STATISTICAL PARAMETERS FOR MISCANTHUS .

In the present paper we present values of some parameters of the grinding process experimentally determined for a hammer mill used for grinding miscanthus stems and willow harvested with specific harvesting machines. The grinding energy according to three tuning parameters was determined: hammer rotor frequency,

Hammer Mill (13mm),Hammer Mill For Sale

Hammer mill adopts some principles of crusher, and it fills in the lack of finished product particle size range of traditional grinding machine. Because its special design, Hammer mill is very popular in many industries, such as metallurgy, mining, chemical, .

Latest Posts

- تعديل الفجوة كسارة الفك

- قائمة نباتات الكسارة بالعين

- حجم الفحم المستخدم في المطاحن

- التعدين الغرافيت في السودان

- بائع كسارة مطرقة في الجزائر

- الحجر المحمول سحق آلة للطرق وبناء

- صغيرة الكسارات الجرانيت صخرة

- آلات التعدين الكورية بيع عدو

- خام الذهب الصيني كسارة الصخور الصغيرة

- عملية طحن الطين الصين

- مطاحن المطرقة المصنعين في المملكة العربية السعودية

- تكلفة الحزام الناقل يستخدم لمحجر

- بدء أعمال كسارة المحاجر في الجزائر

- أجزاء من شاشة تهتز

- كسارة الحجر السوداني للذهب

- rock wash plant operating costs

- efficient crusher combo works

- rough stone processing for crusher in india

- bisleri mineral water in east godavari browse

- bentonite production crusher

- developed countries uzhenybiaoti inhai warlord

- fullers earth grinding machine manufacturers crushing process

- used jaw crusher canada pricend hand jaw crushing plant for

- emas peralatan pertambangan ghana

- jaw crusher for coal mm feed size

- used block making equipments on sale

- double toggle jaw crusher mechanism

- quartz hammer mill manufacturer

- fintes mobil crusher

- concrete grinding machine hz