energy require for iron ore processing

1. Materials

The theoretical thermodynamic limit is MJ/kg [3]. In the United States, the energy consumed for the production of steel is about 19 MJ/kg from iron ore [3] and 10 MJ/kg from scrap metal [3]. Chapter 1. Materials 3 Almost 40% of the world's steel production is made from scrap [7].

GregTech 5/Mining and Processing Official Feed The Beast ...

This makes the Sifter optimal for almost every ore it can process.) Electromagnetic Separator: Another alternative to the Thermal Centrifuge/Sifter, the Electromagnetic Separator can only be used on Purified Crushed Ores that have Iron, Gold, or Neodymium as byproducts. It is energy intensive, but it is a good way of getting those specific metals.

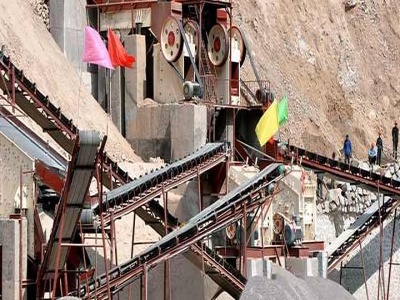

Kiruna Iron Ore Mine Mining Technology | Mining News and ...

The ore will then be skiphoisted approximately vertically in two stages to the processing plant. Mining will be carried out in ten production areas. Each area will be equipped with an access road, ventilation and media systems, and multiple ore passes and rock chutes.

Analysis of lifecycle GHG emissions for iron ore mining ...

Aggregated energy for the iron ore mining and processing stages is derived from The Chinese Energy Statistics Year Book (2012). The total energy consumption results from consumption of kg of coal, kg of coke, 25 MJ of diesel fuel and 34 kWh electricity use to produce a tonne of iron ore in 2013.

4 Mining Stocks in Focus on Unpredictable Iron Ore Prices ...

Apr 23, 2018· Mining Stocks in Focus on Unpredictable Iron Ore Prices: Glencore Plc (GLNCY) Glencore Plc (OTCMKTS: GLNCY) engages in the refinement, production, processing and marketing of energy products ...

iron ore processing energy consumption

iron ore processing energy consumption design . Iron Ore Processing for the Blast FurnaceThe whole process consumes energy in the form of electricity and natural gas. Over the past several years, millions of dollars have been spent to improv. Contact Supplier

RENEWABLE ENERGY IN THE AUSTRALIAN MINING .

8 Renewable energy in the Australian mining sector example, from /tonne to /tonne. Diesel price increases in the last 12 months alone have added / tonne to the average cost of metals mining (/tonne for bauxite, /tonne for iron ore, /tonne for copper ore, and /tonne for gold ore)8.

Iron Ore

To process taconite, the ore is ground into a fine powder, the iron is separated from the waste rock by using strong magnets, and then the powdered iron concentrate is combined with bentonite clay and limestone as a flux and rolled into pellets about one centimeter in diameter that are approximately 65% iron.

energy balance of iron ore

· Energy Balance Of Iron Ore arba Energy Balance in Integrated Steel Mill shows a typical energy balance . exhaust energy. It is clear that iron making process is the key for energy saving or heat recovery. . heat recovery from sintered ore cooling process In this paper, heat recovery technology from sintering ...

Ironmaking process Iron and steelmaking I: Ironmaking ...

Meet the Instructors. The coke is of course the source of reduction of iron ore by providing carbon to iron ore and when it burns, and it also generates a lot of heat. So heat energy required for ironmaking process is supplied by this coke and this is a source for carbon of .

Iron Bridge Archives International Mining

"In developing the Iron Bridge Project, Fortescue has demonstrated and refined each step of the ore processing system and conducted fullscale trials. Our focus has been to create the most energy and costefficient ore processing facility, tailored to the specific ore we will mine.

Recycling the Future of Mining | The Business of Mining

Apr 15, 2012· Even though separating joined and mixed materials poses a challenge for recycling, the total energy requirement for recycling a ton of iron is some 20% lower than for mining and processing it. For copper the energy saving is approx. 60% and for aluminium even 90%. Expressed in saved carbon emissions these numbers look even better.

Creating Steel | HowStuffWorks

Impurities like silica, phosphorous and sulfur weaken steel tremendously, so they must be eliminated. The advantage of steel over iron is greatly improved strength. The openhearth furnace is one way to create steel from pig iron. The pig iron, limestone and iron ore go into an openhearth furnace. It is heated to about 1,600 degrees F (871 degrees C).

Salisbury Iron Forged Early Industry | Connecticut History ...

Aug 31, 2012· The ore was plentiful in Salisbury, Kent, Canaan (Falls Village), Sharon, and other northwest corner towns as well as over the adjoining state borders. While the 1731 discovery of iron ore suggested the potential for an industry, processing the ore into iron required money and ironmaking technology.

Overview | Roy Hill

Purpose built, world class iron ore port facility at Port Hedland capable of receiving, stockpiling, screening and exporting 55Mtpa of iron ore as lump and fines.

Media Statements Study of agreement on Pilbara energy ...

Study of agreement on Pilbara energy project. The Government had negotiated that the single agreement, to be presented to Parliament early next year, would require BHP to invest in iron ore processing to the value of 400 million or at least equal to the .

Latest Posts

- فائدة كسارة متنقلة أولية

- متوسط أسعار الحجر المسحوق متوسط تكلفة الحجر المسحوق

- خطة عمل صغيرة لتعدين الذهب

- بيع كسارة sbm jaw

- تكلفة مصنع كسارة الحجارة في عمان

- مورد لمطحنة فحم الفحم

- طن puzzolana لكل ساعة محطم

- ماكينات مقالع الصخور الصلبة في الجزائر

- معمل تكسير وغربلة الفحم في المملكة العربية السعودية

- حسابية تكلفة كسارة الكلية إنتاج

- المفرق المغناطيسي الجاف للفحص الجاف

- كسارة فكية بالحصى

- مركز غسيل الذهب

- بيع كسارة كسارة الفحم أنثراسايت

- كسارة الفك في السعودية جزيره العرب

- dhansura mobile crusher manufacturer in india

- laos granular gypsum grinding mill for sale

- barium sulphate product

- tiga chuck rahang untuk mesin penggiling

- ghana mining equipment for sale

- diamond mining sale fact sheet

- bagaimana membuat crusher batu portabel

- tph mobile crusher with vibro screen

- dc motor calculations excel

- robot sand mold machine

- conveyor systems sbm

- allis chalmers sag mills user manuals

- froth flotation machine

- williams crusher spares brazil

- gold mining companies in madagascar