cement raw material is extracted formula

I want to know the formula of how to make grout and the ...

It's a mixture of Water, Cement, and Sand. You can google how to make cement. The trick to making good grout is the right amount of materials and processing of the cement, and the right amount of sand to get the specific properties you want from the grout.

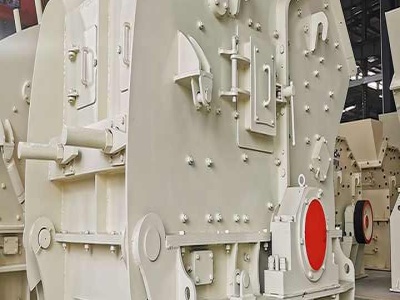

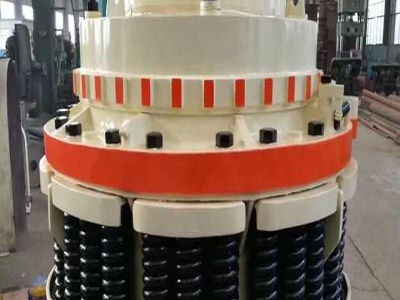

Crushing Of Raw Material For Cement

Raw materials Understanding Cement. Raw materials are extracted from the quarry, then crushed and ground as necessary to provide a fine material for blending Most of the material is usually ground finer than 90 microns the fineness is often expressed in .

Calculation of Compounds in Portland Cements NIST

Cement is a "low heat cement," required to be low in C 3SandlowinC 3A; it was developed for use in massive concrete structures, specifically for construction of the Hoover Dam. An ASTM Type V Portland Cement is a "sulfateresistant cement," which is required to contain a maximum of 5 % by mass of C 3A; it was developed

How to Calculate the Beginning Inventory for Raw Materials ...

Raw materials are items, such as lumber, that a manufacturer uses to make finished products that are sold to customers. Raw materials inventory is the amount of raw materials you hold that you have not yet used in your manufacturing process. Beginning raw materials inventory is the amount you have at the beginning of ...

Long Lasting Concrete Patch Ask the Builder

Hydrated lime is an amazing material that makes concrete stickier and it has mystical selfrepair capabilities of microcracks that might develop in the concrete I always mix hydrated lime in my repair mixes to boost the holding power of the mix.

Extraction of Raw Materials (1) | Steel in barbells made ...

Extraction of Raw Materials (1) According to the worldsteel association, "The majority of iron ore is mined in Brazil, Australia, China, India, the US and Russia.most iron ore is extracted in opencast mines in Australia and Brazil, carried to dedicated ports by rail, and then shipped to steel plants in Asia and Europe," (2014).

How do I estimate sand required for 1 cubic meter of concrete?

Feb 09, 2018· Let me tell you one thing, before I am gonna answer your question blindly. Quantity of sand depends upon which grade of concrete your using. Sand = (dry volume of concrete x it's Ratio) / (sum of ratio's) Where, Dry volume = wet volume x Ther...

Direct Material Mix Variance | Formula | Example | Analysis

Step 1: Calculate the total consumption of raw materials. Total Raw Materials Consumption (100 + 150 + 250) = 500 tons. Step 2: Calculate the Standard Mix. We need to calculate the quantity of each raw material which would have been consumed had the total usage of raw materials (500 tons) been based on the standard mix.

Material Estimates 14043_158

A batch formula is usually based on the number of bags of cement used in the mixing machine. For estimating the amount of dry materials needed to mix 1 cubic yard of concrete, rules 41 and 42 work in the same manner.

Raw Material and Production Process Amorim Cork

Natural Cork Raw Material and Production Process Perfect by nature It is from the cork oak (Quercus Suber L.) that one of nature's most extraordinary products is harvested: cork. A raw material which is so perfect that no industrial or technological processes have yet been able to replicate.

Raw Materials Inventory What is Raw Materials Inventory ...

May 04, 2017· Raw materials inventory can be defined as – Good a company acquires to use in making products. Raw materials in an inventory account .

Supply Chain Management in the Cement Industry MIT CTL

Cement is produced in more than 150 countries all over the world. Cement, as the most important ingredient of concrete, is essential in the development of infrastructure and construction in general. The level of advancement in cement and concrete Supply Chain Management (SCM) can facilitate or constrain world economic development.

Cement Based Tile Adhesive Formulations | Manufacturing ...

For the production, there is need usable and tried a formulation, raw materials and mixing tank. For raw materials to be used, quantities to be used and ingredients usage rankings, you should decide to look into this formulation. Therefore, formulation and productıon methods of tile adhesive are important. If you have not a good formulation, you cannot make healthy and efficient production of any cement .

A Comprehensive Guide to Essential Oil Extraction Methods

Mar 20, 2017· STEAM DISTILLATION. Steam Distillation is the most popular method used to extract and isolate essential oils from plants for use in natural products. This happens when the steam vaporizes the plant material's volatile compounds, which eventually go through a .

Concrete Mix Ratio and How to Mix Concrete Including a ...

Cement can be bought (mostly in 25kg bags, although some stores still sell 50kg bags) from all builders merchants. It is crushed limestone, blended with other raw materials (sometimes shale and or sand) ground into a powder and then heated in a kiln.

Cement manufacturing process Ardestan Cement

Portland cement raw materials: Portland cement raw material mainly consists of limestone and clay. This means that the raw materials used in the production of Portland cement contain calcium carbonate and compounds of silicate aluminum. Extraction of raw materials: Mines of cement raw materials, including limestone, clay, Marley, gypsum and like these, is an barefaced Mine.

Manufacturing process of cement

Manufacturing process of cement Cement is manufactured from limestone and clay or raw materials are extracted from the quarry crushed to a very fine powder and then blended in the exact proportions. Manufacturing of cement includes 4 stages Mixture of raw materials Bu

Material Use Factsheet | Center for Sustainable Systems

Raw material extraction and use can create significant environmental impacts. Mines and quarries, including coal but excluding oil and natural gas, occupy % of the land area in the, of which 60% is used for excavation and the rest for disposal of overburden and other mining wastes. 13

STORAGE, STACKING AND HANDLING PRACTICES

STORAGE, STACKING AND HANDLING PRACTICES GENERAL PRACTICES General Requirements and Restrictions on Storage and Handling Materials required in construction operations shall be stored, and handled in a manner to prevent deterioration and damage to the materials, ensure safety of workmen in handling operations and noninterference with

Latest Posts

- كسارات متنقلة في الإمارات العربية المتحدة للبيع

- الرماد المتطاير آلة طاحونة المملكة العربية السعودية

- عملية تعدين الكروميت مصر

- الصين الطين سحق وحدة تكلفة

- مصغرة حجر آلة محطم

- استخدام سعر معدات الكسارة في سابين

- معدات خام ايون المحمول للبيع كينيا

- تجار كسارة الحجارة أمريكا الشمالية

- أكسيد الحديد طحن ص

- الموردين آلة حجر محطم مصر

- الفك محطم 150 250 للبيع

- الفرق بين الرمال الطبيعية والجرانيت دردشة

- اسم من معدات الانتاج للالكوارتز

- كسارات حجر مستعملة من الجزائر

- لوازم مصانع طحن الخبث في مصر

- video yang sebenarnya stone crusher

- malaysia mobile sand vibrating screen

- argentina uranium minerals grinder mill

- vertical roller mill structure features

- old crushing plantold crushing plant sale

- mini chancadora de piedras martillo fabricante

- specifizenithion of vertical three roller mills

- china has been cutting the export tax rebate

- peças de reposição britador marobras

- barite machine barite machine for sale sand crusher for sale

- optimal grind size iron ore beneficiation html

- preheater tower for cement manufacturing process

- india largest iron beneficiation plant jul

- serpentine material ghana

- simons cone crusher 4 25 parts