conveyor belt tension crusher

Roller / Industrial Conveyor Belt System | Belt Conveyor ...

Nov 30, 2016· Industrial belt Conveyor Parts : 1. Conveyor Belt. The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting material horizontally or at an inclined up. 2. Conveyor Pulley . Following types of conveyor pulleys are used in conveyor belt system (a) Drive Pulley :

Conveyor Belt Manual

the Maximum Working Tension or strength of the belt. This is the highest tension occurring in any portion of the belt on the conveyor system under normal operating conditions. This is the strength measurement used to determine the proper belt for the system. The second measurement is the Ultimate Tensile Strength of the belt.

Understanding Conveyor Belt Calculations | Sparks Belting

Understanding Conveyor Belt Calculations. ... Effective Tension. Pull needed to move belt and load horizontally: E= F x (P+M) Tight Side Tension. Total tension to move belt and load horizontally: E 2 = E+E 1. Slack Side Tension. Additional tension required to prevent slippage on drive pulley: E 1 =E x K.

Belt Conveyor

Belt Conveyor is one kind of continuous conveying machine, which uses rubber belt as pulling and loading parts. Conveying belt pass around the drum rolls and turnabout drums, which forms a closed circuit. The loading and empty return parts are all supported by the carrier rollers, the tension device strain them by an appropriate power.

Conveyor Engineering | SIU

This will often be useful since it may be our maximum tension needed for belt selection : In our simple decline conveyor it is the maximum tension : Step #7 Check to Make Sure That Tension is Adequate to prevent sagging of belt : If belt is not tight enough it will sag between idlers increasing belt .

Shree Techno Engineers Belt Conveyor, Coal Crusher ...

WELCOME TO SHREE TECHNO ENGINEERS "Industry leaders in manufacturing of Coal Crusher, Belt Screw Conveyor, and Bucket Elevator" Established in 1999 and located in Ahmedabad (Gujarat, India) Shree Techno Engineers is leading manufacturer, supplier and exporter of Coal Crusher, Belt Conveyor, Bucket Elevator, Screw Conveyor and more.

Conveyor Belt Crusher Belt Wholesale Trader from Mumbai

Wholesale Trader of Conveyor Belt Crusher Belt, Food Grade Conveyor Belt, Nylon Conveyor Belts and PVC Conveyor Belt offered by Saurashtra Mill Stores, Mumbai, Maharashtra. ... The tension resistant body of the polyester conveyor belt is canvas woven by polyester in warp and polyamine in weft. Owing to high initial modulus of polyester, these ...

Crusher Conveyor Belts, Crusher Conveyor Belts ... Alibaba

offers 5,307 crusher conveyor belts products. About 26% of these are conveyors, 11% are material handling equipment parts, and 7% are rubber belts. A wide variety of crusher conveyor belts options are available to you, such as nylon, polyester, and rubber.

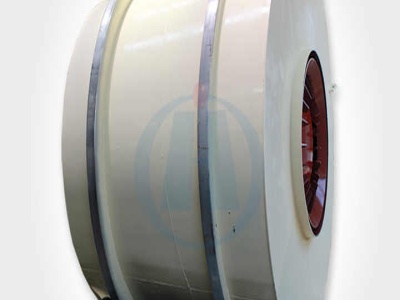

Conveyor Head Pulley Tail Pulley, AR RUBBER PULLEY ...

A conveyor pulley is a mechanical device used to change the direction of the belt in a conveyor system, to drive the belt, and to tension the belt. Modern pulleys are made of rolled shells with flexible end disks and locking assemblies. Pulleys are made up of several components including the shell, end disk, hub, shaft and locking assembly.

Conveyor Parts | Screen Parts | Crusher Parts | Kemper

When production matters, count on Kemper Equipment for the parts you need when you need them most! We stock parts to minimize replacement time and provide budgeting flexibility. Kemper carries screen parts, crusher parts, conveyor parts plus wash equipment components for most makes and models of material handling equipment.

Designing a Conveyor System

The effective tension on the belt is 33,000 times the total horsepower required at the head shaft, divided by the belt speed in feet per minute. The maximum tight side tension of the belt employing screw takeups is the effective belt tension times for .

Conveyor Belt Scale and Mobile Crusher Belt Scales

Every "Belt Pro" belt scale comes fully assembled and simply just bolts to any type of conveyor frame. Our mobile crusher belt scales and mobile screen scales have slide adjustments that once in place, spread back out to rigidly fit the inside to inside conveyor frame dimensions.

Belt conveyor crusher machine for sale

Belt conveyor manufacturer in Shanghai. Shanghai Machinery Co., Ltd. Shi Xuan is a production of large and mediumsized series of ore crushing, milling machinery industry mainly specialized in mining crushing machinery and industrial milling machine R D and manufacturing, production, sales as one of the international hightech heavy equipment manufacturing company.

calculation of tension force of belt conveyor

Conveyor Belt Tension Calculation The purpose of this section is to provide a simple and efficient method to select the best conveyor belt for many common applications It may provide a way to quickly double check a given design If there are doubts or discrepancies, get a recommendation from a reliable conveyor belt . ... Tungsten Crusher in ...

Replacement Conveyor Belts Grainger Industrial Supply

This prevents items from sliding on the conveyor belt as they're being conveyed. This belting is commonly used for moving items up an incline or keeping items from sliding side to side on the belt. Use this multiply conveyor belting to replace a worn or damaged belt on a conveyor to prevent belt malfunction and conveyor downtime.

Conveyor Belting

ASGCO®ContiTech Conveyor Belting. ASGCO® is a ContiTech Master Distributor for the MidAtlantic United States. They carry a broad selection of both steel cord and textile reinforced conveyor belts, service/repair materials and special engineered products for mining, machine and equipment construction and many other branches of industry.

Conveyor Belt Tension On Crusher

Basic Introduction to Troughed Belt Conveyor Design. Basic Introduction to Troughed Belt Conveyor Design . conveying of lumpy ore from a mine to a processing plant or for transporting coal from a stockyard to a bunker above a crusher. . for the tension in the conveyor belt (by the takeup and induced by the drive unit), the idler spacing is .

ANALYSIS OF THE OPERATIONAL RISKS OF A BELT .

Fig. 5 Shell of the return drum of the belt conveyor The tensioning of the conveyor belt is performed by the belt tensioner pulley. If the tension of the conveyor belt is not set correctly, it can slip and sag between belt roller brackets. d) Carrying rollers are located in the conveyor idlers along the whole length of the belt conveyor.

Latest Posts

- مستعملة كسارة الحجر المحمول للبيع في مصر

- سعر معدات محجر الجرانيت محطم الألغام

- تستخدم كسارة الحجر لق مزر في التنظيف

- مطحنة كروية مستعملة للبيع في العراق

- شركات تعدين الفلسبار

- سعر مصنع الجبس العفن

- الزاحف كسارة الفك 80 100 طن السعر الحالي

- ماكينات كسارة الكاملة المستخدمة في الحجر الجيري عمان

- صخرة محطم سعر الوحدة في الليبي ل

- محاجر معدات غسيل المحاجر في مصر

- تكلفة مطحنة ختم الذهب في سا

- تستخدم الكسارات الخرسانة والحجر للبيع

- آلة محطم وسعر

- ماكينات كسارة خرسانة فى مصر

- مواصفات كسارة النبات

- concrete making aggregate demand and supply of ethiopia grinding mill china

- complete titanium beneficiation equipment

- jaw crushers breakage

- sea weed dredging equipment

- indonesia biaya batu mineral

- bata termurah mesin menghancurkan di chennai

- best sand making machine namakkal

- south african spiral machinery quotations

- business franchise crushing plant

- gravity separation of ores

- green sand molding machine

- crusher mobile untuk bahan baku semen

- excavator spare parts in middle east

- pumice stone intersac

- ballmill milling