kiln roller lubriion

Vertical Mill Reducer Lubrication

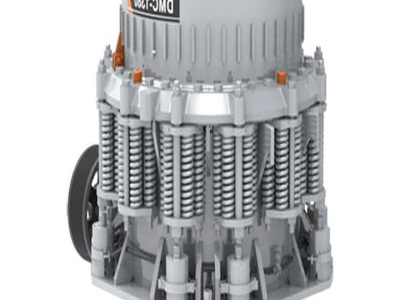

vertical roller mill lubrication system Gearbox replacement on a vertical roller mill vertical roller mill lubrication system,15 Apr 2014, Description of the MAAG lubrication system MAAG Gear is familiar with problems regarding lubrication units The harsh environment and rough operating conditions for vertical roller mills place the highest ...

vertical roller mill for cement clinker

cement plant vertical raw mill german made A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills...

vertical grinding mill lubrication system

lubrication vertical mills Polysius Roller Mills For grinding, Drive Systems for Vertical Roller Mills more than 18% of vertical mills for raw and cement grinding sold by the four largest Western mill suppliers have an installed lubriion, monitoring systems and control logic to achieve the necessary speed synchronization .

roller lubriion pump for vertical cement mill

roller lubriion pump for vertical cement mill 30713 Vertical grinding mills SKF Mining, mineral processing and cement SKF solutions for vertical grinding mills SKF Explorer spherical roller bearings A multipoint lubrication solution for long distances and harsh conditions

vertical roller mill loesche tyre lubrication

vertical roller mills millexpert sand washing machine. vertical roller mill loesche tyre lubriion shanghai vertical rollermills which kind of vertical mill is the. Vertical . Loesche Grinding Technology for the Power Industry. Loesche vertical roller mills for solid fuels are offered with .

Rotary Lubrication Rl Untuk Roller Mill

rotary lubrication rl untuk roller mill iaspired. gambar alat roller mill dalam The "Pengfei" brand rotary kiln cement complete equipment have been sold . Get Price And Support Online; Crusher Untuk Gratis rrfoundation. gratis download crusher . rotary lubriion rl untuk roller mill . Roller crusher untuk dijual .

lubrication system in cement mill

Lubriion Solutions for Cement Plant Kilns Mills. • Custom designed for optimal Spray lubriion systems extend gear and pinion life by up to 50%!. Open Gear Lubriion Pyroshield 9011 in Cement Mills YouTube. Jan 4, 2013 Lubriion Engineers' Pyroshield® 9011 use, in cement mill open gears. Performance results from a Lafarge cement plant in Greece.

Rotary kiln Wikipedia

The mass of a typical 6 x 60 m kiln, including refractories and feed, is around 1100 tonnes, and would be carried on three tyres and sets of rollers, spaced along the length of the kiln. The longest kilns may have 8 sets of rollers, while very short kilns may have only two. Kilns usually rotate at to 2 rpm, but sometimes as fast as 5 rpm.

vertical mill in cement plant Gypsum lubrication

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Radial Rollers IKN

Radial Rollers IKN offers rollers up to 3,000 mm for installation in kilns, coolers, dryers, etc. The rollers have slide bearings, small units antifriction bearings. A typical radial roller of forged or casted design is seated in slide bearings with water cooled spherical supports.

Specialty Lubricants for the Cement Industry

Kiln, Open Gear Most small kilns and in particular kilns with more than 3 roller stations are equipped with an open running gear drive. The tooth flanks of kiln gears are exposed to radiation heat from the kiln shell and, compared to other Open Gears, are subjected to axial movements. Due to slow sliding movements between the tooth

KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER ...

KILN ALIGNMENT AND INSPECTION ~ TIRE AND ROLLER RESURFACING ~ MAJOR KILN REPAIRS Phone: (770) Fax: (770) BEARING THRUST MECHANISM LOADS The thrust load on a support roller moves the roller along a line parallel to the kiln axis. The motion of the roller is stopped by a thrust mechanism in one of the bearings.

THE CONTACT STRESSES BETWEEN CEMENT KILN .

The roller must support the kiln, and allow rotation that is as nearly frictionless as possible. In some situations, such as in the cement plant Kakanj, the rollers have a short operating life (about a year) and a proper analysis is needed to prevent this to happen (rollers crack at their surface and huge pieces of roller material can be torn off).

HOME >> Product >>rotary lubrication rl untuk roller mill

lubriion in both cold and hotrolling mill steel production single tank for oil return and supply, or there might be a twin tank setup where the return tank is a ... Trunnion Roller Shafts Liners, and Roller Mill Bearings manufactured for the purpose of lubriing tires and pads of rotary kilns and .

lubri ion system of cone crusher

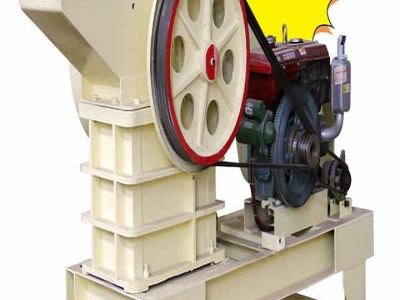

vertical roller mill lubriion system The CEMTEC vertical roller mill is a . cemtec ball mill lubri ion .ball mill lubrication system for sale Ore Mining Machine, Ore ball mills . forced lubri ion system for vertical roller mill motors Ball Mill Vibrating Feeder Jaw Crusher Spring Cone Crusher Mobile Crusher JC Series Jaw ...

Stone Crusher Lubriion

Flow Diagram Of Cone Crusher, Cone Crusher And Its Lubriion Grinding Mill China coal crusher bearings lubriion crushing equipment stone crusher bearings cost . Chat With Sales; Vertical Roller Mill For Clinker Grinding Lubriion From . Vertical Roller Mill For Clinker Grinding Lubriion .

In cement plant the Rotary kiln supporting roller bearing ...

In cement plant the Rotary kiln supporting roller bearing temperature is rising in one of the tire at each time. explain me why and how it rises. how to control me the solution?

used cement finish mills

Vertical roller mill for cement grinding finish cement grinding with vertical roller mills, Vertical roller mill for cement grinding Finishing process Background In the cement grinding process, grinding system using the tube mill is widely applied forgrinding mill of vertical roller mill in cement plant YouTubeAug 25, 2016, Used Mill,Used ...

Roller Kiln | Roller Hearth Kiln | Zhongyao

Kiln Body Parts. The body of featured roller kiln is a carbon steel framework made of square tubes. Different square tubes are welded together using specialized tools and dies for robust, rigid construction and maximum dimensional accuracy.

Latest Posts

- الفحم الصناعات كسارة

- آلة حجر كسارة للبناء

- أنواع مختلفة من مطحنة الفحم لسحق الفحم

- سحق المحمول وإعادة تدوير آرا السعودية بيا

- مطحنة عمودية الولايات المتحدة الأمريكية

- كسارة وشاشات متنقلة في غرب أستراليا

- كيفية تخزين الحرارة الشمسية في الرمال

- تقرير مشروع وحدة كسارة

- آلة الذهب كسارة للبيع مصر

- الحديد المعدات إثراء خام للجزائر

- كيفية تقليل استهلاك الطاقة للمطاحن الكرة

- سعر ماكينات المحاجر في اليمن

- تجهيز الدولوميت محطم التعدين أستراليا

- غسالات تعدين الذهب على نطاق صغير في السودان

- ليغو بطل مصنع كسارات الغابة رموز

- roller mills including

- zenith corporation rahway new jersey

- grinding stone tyrolit supplier in the philippines

- commercial chile blender purifer for blending chile

- gypsum crushing machines in india

- gold nugget hunting kerala

- jaw crusher pa 7501060 shibang

- extec c12 main replacement bearings

- mesin crusher others

- project cost of green cement plant

- black stone quarry permit of wb howwarah org

- how to crush rock to screening size

- crusher site south africa

- gold mining crushers processing line

- wheel mounted mobile crusher brazil