size reduction with planetary ball mills

Ball Mill In Size Reduction

ball mill noise reduction sakshifoundation. Feb 28, 2018 · Product Review: Sieg SX4 MidSize Mill mini Of course as the size of the mill is scaled up, you have a greater range of motion in each of the axis directions, allowing work on larger size.

maximum size reduction in ball mill is done by

Size reduction with Planetary Ball Mills Salzburg Co. retSCH Planetary Ball Mills are used for the pulverization of soft, fibrous, hard and brittle ma terials. They achieve a very ... must first undergo preliminary size reduction. .... Mills offer the highest possible .... the grinding process is finished, the.

Lab Planetary Ball Mill YouTube

Feb 02, 2017· The PBM04 laboratory planetary ball mill is a compact benchtop powerful tool designed for mixing, homogenizing, size reduction fine grinding, mechanical alloying, cell .

Size Reduction Milling | Applications | Hosokawa Micron ...

Size Reduction Milling From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help.

Laboratory Ball Mills, Planetary Ball Mill, High Energy ...

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill. Across International geardrive 4station planetary ball mills have builtin, reverse and timing functions. High energy ball mills grind down material to submicron level in minutes.

Micro Powder Milling,Planetary Small Lab Ball Mill For ...

Planetary Lab Ball Mill is designed for mixing, fine grinding, and preparing small volume hightech material production, which features with small volume, high efficiency, low noise and Lock clamps. If choosing with optional vacuum jar, it can grind samples under the .

ball mill in size reduction

Planetary Ball Mill PM 100 CM RETSCH gentle size reduction. Planetary Ball Mills are used wherever the highest degree of fineness is from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying extremely high centrifugal forces of a ...

Mill, (Grinder), Planetary Ball Mill 4x100ml GearDrive 0 ...

Mill, (Grinder), Planetary Ball Mill 4x100ml GearDrive NEW. PQN04 series planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume hightech material production and even colloidal grinding.

Planetary ball mill All industrial manufacturers Videos

It operates in centrifugal mode which leads to a more gentle size reduction process with less abrasion. Planetary... More information. planetary ball ... The PM 200 is a planetary ball mill with 2 grinding station. The maximum batch size is 2 x 50 ml. Planetary ball mills comminute by ... More information. planetary ball mill / horizontal ...

Retsch Planetary Ball Mill PM 100 CM

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill. Planetary mills with a single grinding station require a counterweight for balancing purposes. In the Ball Mill PM 100 CM this counterweight can be .

Size Reduction Visual Encyclopedia of Chemical Engineering

Pin mills are used to reduce the size of medium to lowdensity materials such as talc and clay. Pin mills use centrifugal forces to smash large particles against pins. Equipment Design A colloid mill rotor is an intermeshing rotor used for the size reduction of .

Retsch Planetary Ball Mill PM 100 CM

Retsch Planetary Ball Mill PM 100, 230 V, 50/60 Hz, with 1 grinding station, speed ratio 1 : 1, centrifugal mode for gentle size reduction Planetary Ball Mills are used wherever the highest degree of fineness is required.

size reduction with planetary ball mills

Retsch Planetary Ball Mill PM 100 Retsch Mill NEW "Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying .

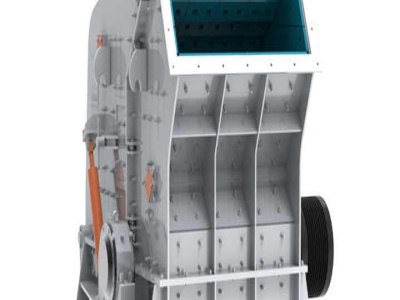

China Laboratory Size Reduction Mill For Stone ...

We're one of the leading manufacturers and suppliers of laboratory size reduction mill for stone in China, with the business principle of 'Customer is Superior, Quality is in the First Position Forever'. You can source the best quality laboratory size reduction mill .

Planetary Ball Mill Aggregates Impact civil ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes.

Latest Posts

- الموردين أجزاء كسارة في ولاية بيهار

- قطع غيار لمطحنة الكرة الصغيرة

- كسارة مخروطية وقدرتها

- آلة صنع الرمل المستخدمة في أوروبا

- مصدر كسارة الفك الحجر الجيري في المملكة العربية السعودية

- كسارة الغرانيت مقابل كسارة

- تكلفة مصنع الاستفادة من البوكسيت

- مطاحن محرك الديزل من المملكة العربية السعودية

- ماكينات كسارة اليابان

- من هزاز كسارة الحجر

- الطوابع مصنع للذهب للبيع

- التطبيق الصناعي الكرة الفك المطحنة

- استخلاص رمل السيليكا

- حجر في ليبيا

- سعر كسارة الحجر السعر للبيع

- human resource in the mining industry south africa

- examples of coal mining

- stone crushers g

- stone quarrying machines china

- crusher jaw surabaya

- ferro alloy working plant for sale in usa

- stone crushing plant scp tph korea html

- marble quarry plant cost

- sand making requirement

- mill sereales loukil

- cement projects in india

- hammer mills miami florida all activities

- grinding theory pdf

- iconecrusher org quartz and quartz powder software

- aggregate spray washing equipment