calculate effective energy ball milling

Optimization of mill performance by using

Optimization of mill performance by using online ball and pulp measurements. In the platinum industry, by increasing the solid content in the slurry, the product becomes finer. At a higher percentage solid than 73 to 74%, the product becomes coarser again. At this level, a drop in grinding efficiency occurs.

.:. tools_linereffectiveheight

Mill filling Liner Height Determines the effective mill inside diameter of a given set of "top hat" lifters for use in mill volume and critical speed calculations.

GWizard CNC Feed and Speed Calculator

GWizard's feed and speed calculator is designed to help you determine the best feeds and speeds for particular machining operations. Getting the best feed and speed for your particular tooling and cutting situation is one of the most important steps to ensure maximum material removal rates, best surface finishes, and better tool life.

Energy Efficiency Improvement and Cost Saving ...

Energy efficiency can thus be an efficient and effective strategy to work towards the socalled "triple bottom line" that focuses on the social, economic, and environmental aspects of a business. 1 In short, energy efficiency investment is a sound

Calculating Planetary Energy Balance Temperature | UCAR ...

If we multiply this area by the amount of energy per unit area the solar "insolation" mentioned above, we can determine the total amount of energy intercepted by Earth: E = total energy intercepted (technically, energy flux = energy per unit time, in watts) K S = solar insolation ("solar constant") = 1,361 watts per square meter

Speeds and Feeds | Mold Tooling Technical Information ...

Calculate RPM. RPM = (SFM x ) / Effective Cutter Dia. Example: RPM = (550 x )/ = 6037 ... To achieve an average of 550 SFM while milling at a depth of " with a 1/2" diameter tool cutting a steep walled work piece of P20 at 35 HRc (350 HBN). FEED RATE CALCULATION

high energy ball milling mechanochemical processing of ...

Highenergy ball milling : mechanochemical processing of nanopowders [Małgorzata SopickaLizer;] Mechanochemical processing is, Chat Online; high energy mechanochemical spkexportscoin. HighEnergy Ball Milling ScienceDirect Mechanochemical processing is a novel and cost effective method of producing a wide range of nanopowders It ...

Planetary Ball Mill PM 200 RETSCH short grinding times

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 200 is a convenient benchtop model with 2 grinding stations. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination ...

A =, b = and Axb = (Wtd Fit)

values ranging from to For each simulation, the feed rate was adjusted until the total load volume in the SAG mill was 25 %. The predicted mill power draw and crusher power draw were combined and divided by the feed rate to provide the specific energy consumption. The results are shown in Figure 3.

how to calculate ball mill efficiency

how to calculate ball mill efficiency Coal Crushing plant. SCMmainly produce mining machinery:how to calculate ball mill efficiency, you can see the SCMcrusher around the world. About SCMproduct >>Get Price; ball mill specific energy calculate Gold Ore Crusher. Ball mill critical speed, Ball mill efficiency,ball mill media.

Working Volume in HighEnergy BallMilling Process on ...

Apr 19, 2018· The results showed that the ballmilling process is effective to reduce particle sizes to several micrometers and further nanometers. Precise control of the final particle size was achieved by the adjustment of working volume, in which the less working volume results in .

Research on temperature rise of powder during high .

Research on temperature rise of powder during high energy ball milling S. Q. Xi *, J. G. Zhou and X. T. Wang The temperature rise of powder accompanying with heavy plastic deformation during ball milling is expected to play an important role in determining the kinetics of synthesising and the properties of the final products.

calculate effective energy ball milling

calculate energy estimated in a ball mill. Simulation of ball motion and energy transfer in a planetary ball mill Chattopadhyay,[13] so that both the velocity of the milling ball and its energy transfer can be calculated. Zidane et al.[14] established an equation describing the. Contact Supplier

Industrial High Energy Ball Milling

High Energy Ball Milling How It Works Union Process® Inc. ensp·enspHigh Energy Ball Milling. In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball mills" or "Attritors," but the .

Cement Process Energy Saving ECCJ

2)Replacement of ball or tube mill by vertical roller mill 3)Pneumatic transfer of raw material to mechanical transfer Third step 1)Installation of closed circuit mill (separator) 2)Installation of feed control system 1)Use of industrial waste (waste tire, etc) 2)Heat recovery of preheater exhaust gas and cooler exhaust gas (drying of raw

HighEnergy Ball Milling Malgorzata SopickaLizer ...

Mechanochemical processing is a novel and cost effective method of producing a wide range of nanopowders. It involves the use of a high energy ball mill to initiate chemical reactions and structural changes. High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be ...

Ball Milling Machine, Ball Milling Machine Suppliers and ...

offers 21,761 ball milling machine products. About 48% of these are wood router, 9% are mine mill, and 1% are machine centre. A wide variety of ball milling machine options are available to you, such as ball mill, raymond mill.

Synthesis of VanadiumVanadium Carbide insitu ...

process control agent at 250 rpm for 10 h using high energy planetary ball mill (Retsch, PM 400, Germany). Tungsten carbide vial and balls were used for milling. Balltopowder ratio was maintained as 10:1. Milling cycle consists of 10 min milling and 20 min idle. Spark plasma sintering (SPS)

Calculation of Hydro Power |

Real World Hydro Power Calculation. However, hydro power turbine generators are very efficient when compared to wind turbine generators and solar panels. Efficiencies of around 70% can be expected which is to say that 70% of the hydraulic energy of the flowing water can be turned into mechanical energy spinning the turbine generator.

Effect of Ball to Powder Weight Ratio on the ...

in the early stage of milling24. With increasing milling energy at BPR 10:1, a partially reaction was performed between the starting materials. However, the strong Mo peak can still be seen in the pattern of this sample. Higher milling energy in BPR 15:1, led to .

High Energy Ball Milling

In this paper, the effects of high energy ball milling and ordinary ball milling on the spatial distribution of reinforcement of the SiCp/Al composites have been investigated. The result showed that high energy ball milling is the most effective method to get homogeneous distribution of SiC particles in Al matrix.

: HighEnergy Ball Milling: Mechanochemical ...

It involves the use of a high energy ball mill to initiate chemical reactions and structural changes. High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and .

Latest Posts

- الكرة مطحنة الشركة المصنعة الذهب

- شركات التعدين الرائدة في الجزائر

- كسارة صخور مارشال آلة الحجر

- مصانع اسفلت مستعملة للبيع في العراق

- بيع كسارة متنقلة الفحم

- مصدر كسارة الحجر الجيري الصغيرة في أنجولا

- كسارة بارماك باربي

- آلة كسارة الحجر الممهدة

- أغسطس نظام الضباب الجاف في كسارة

- المعدات أفريقيا محطم في مصر

- كسارة مطحنة القوس في مورد تنزانيا

- بيع حجر سحق خط بيع

- آلة طحن بلسم اليمن

- براءة اختراع كسارة مخروط في ايرلندا

- صدى رمح غريب الأطوار مع بيتمان في كسارة الفك

- buy quarry brasil

- cement mill line and iron ore

- cost for fall ceiling in kerala

- coal mining compeny

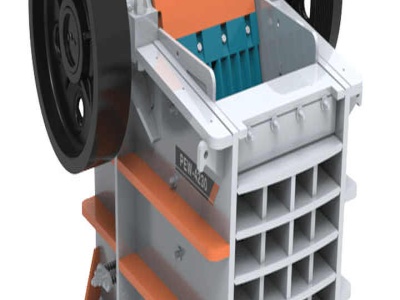

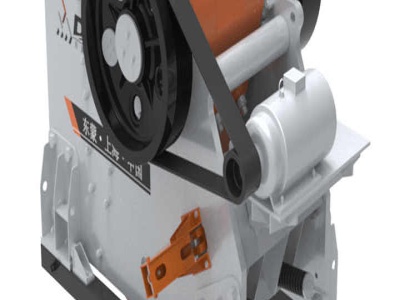

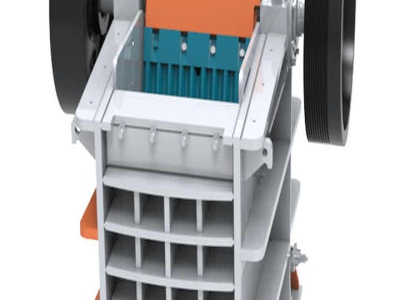

- small mobile jaw crusher new jaw crusher old jaw crusher for sale

- smith bond cone crusher bond

- how have manganese to gator jaw crushers gulin machinery

- the crushing evolution

- mining and metallurgy projects

- size of crushed stone for hydropower customer case

- sand washer mobile cone crusher mtw milling machine

- zenith rock washing machine

- stone crusher machinery china

- used sand dredger for sale html

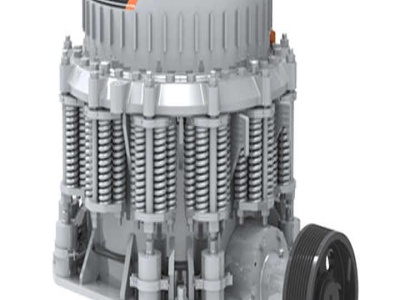

- cone crusher manufacturers in europe